I've seen this asked a couple of times so I thought I'd share how I put a 2 speed in my Traxxas Rustler.

Some background:

This was my first nitro RC. I've been working on cars all my life but my background is IT and Engineering. I got the stadium truck from my dad. He bought it probably close to 15 years ago. He did the break in and started tuning the carb and the throttle hung and it met a curb. He put it in a box and that's where it laid until I asked him about it this past March. He gave me everything he had for it. When he hit the curb he broke the upper chassis deck which cost me $10 from our local RC shop. While I was there I decided to do the power up program and swap the old receiver and transmitter with a new TQI one and add a full waterproof receiver box.

It took me a couple of hors of cleaning out the carb with brake cleaner and q tips before it'd slide like butter.

Next was the motor. I knew it was seized because I couldn't move it by hand at all. I took the glow plug out and added a couple of drops of 5w30 in the head. I 3d printed an adapter for the one way bearing with a 17mm hex on it so I could spin the motor with a ratchet. I heated up the block with a heat gun and tried to wiggle the crank back and forth. I sprayed some WD40 to try and break down the rust. very slowly did it start to move until eventually I heard a metallic click and the crank moved freely. I used the ratchet until my hand got tired and put the 17mm on my 1/4" impact. Added some more 5w30 and spun the motor very slowly. After a couple of minutes I'd spin faster and faster until the impact was full speed. Slapped it all back together and the damn thing ran.

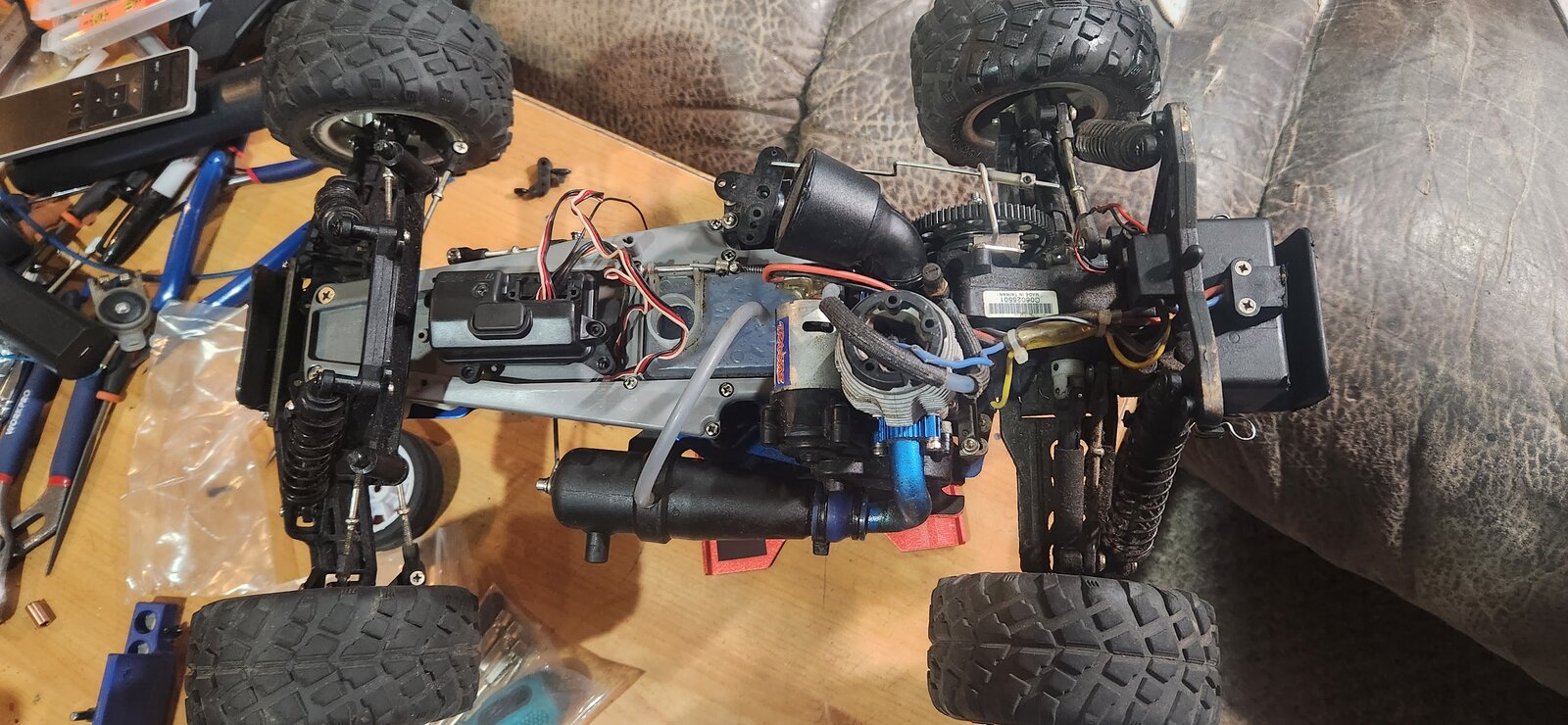

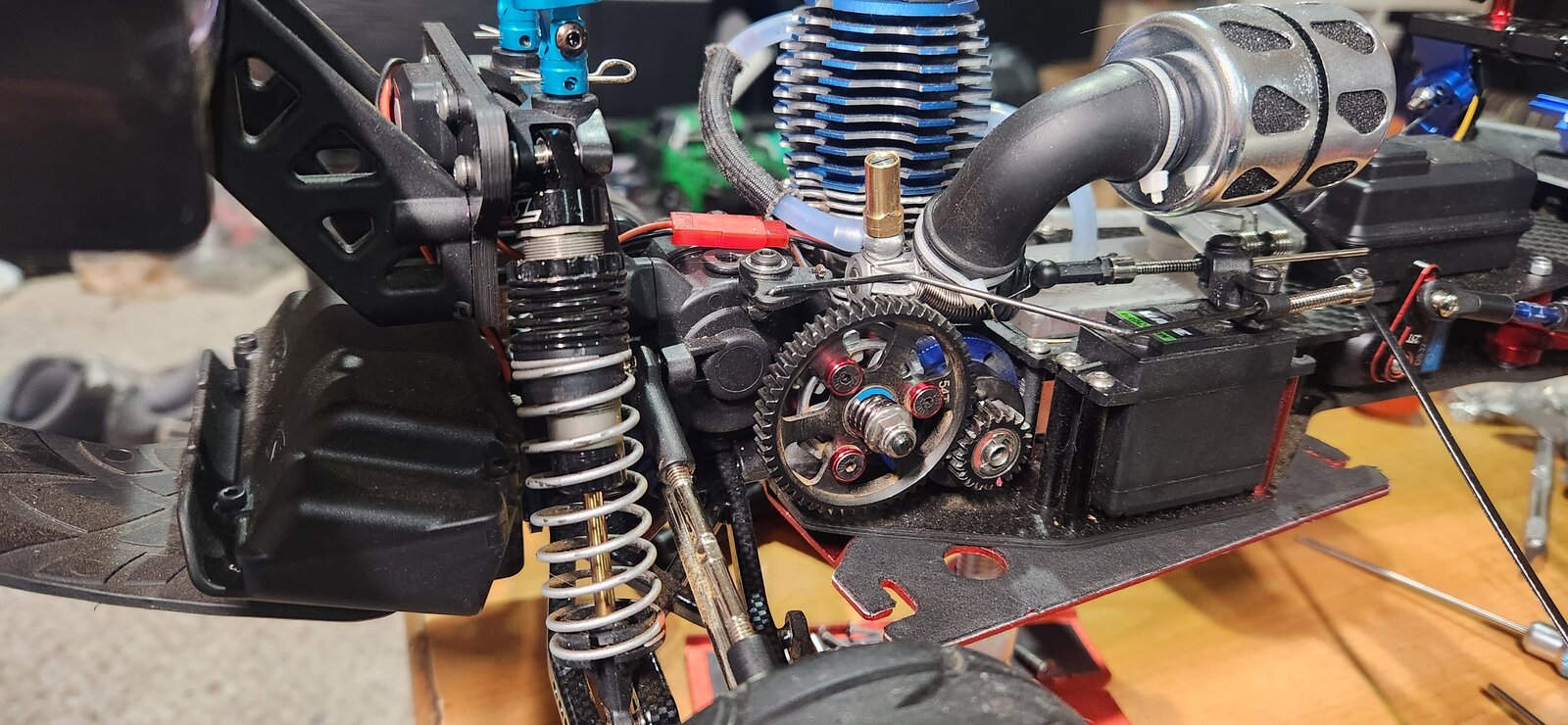

I bought a HPI Savage X. The Rustler took the back seat for a while but I did swap the 2.5r out for another 2.5r using the power up program. But I decided to do something completely ridiculous with my rustler. First I decided to put a HPI 4.6 big block in it. Nowhere near practical but honestly I wanted to see if it'd work. I had to cut a custom carbon fiber chassis plate. I did this in my backyard with a dremel, a drill press and the original chassis plate as a template. The aluminum parts in the picture are from Integy and are actually from a Rustler VXL.

I took the 4.6 out and put it in my Revo and slapped my Dynamite 19 back in the rustler but I wanted more out of it.

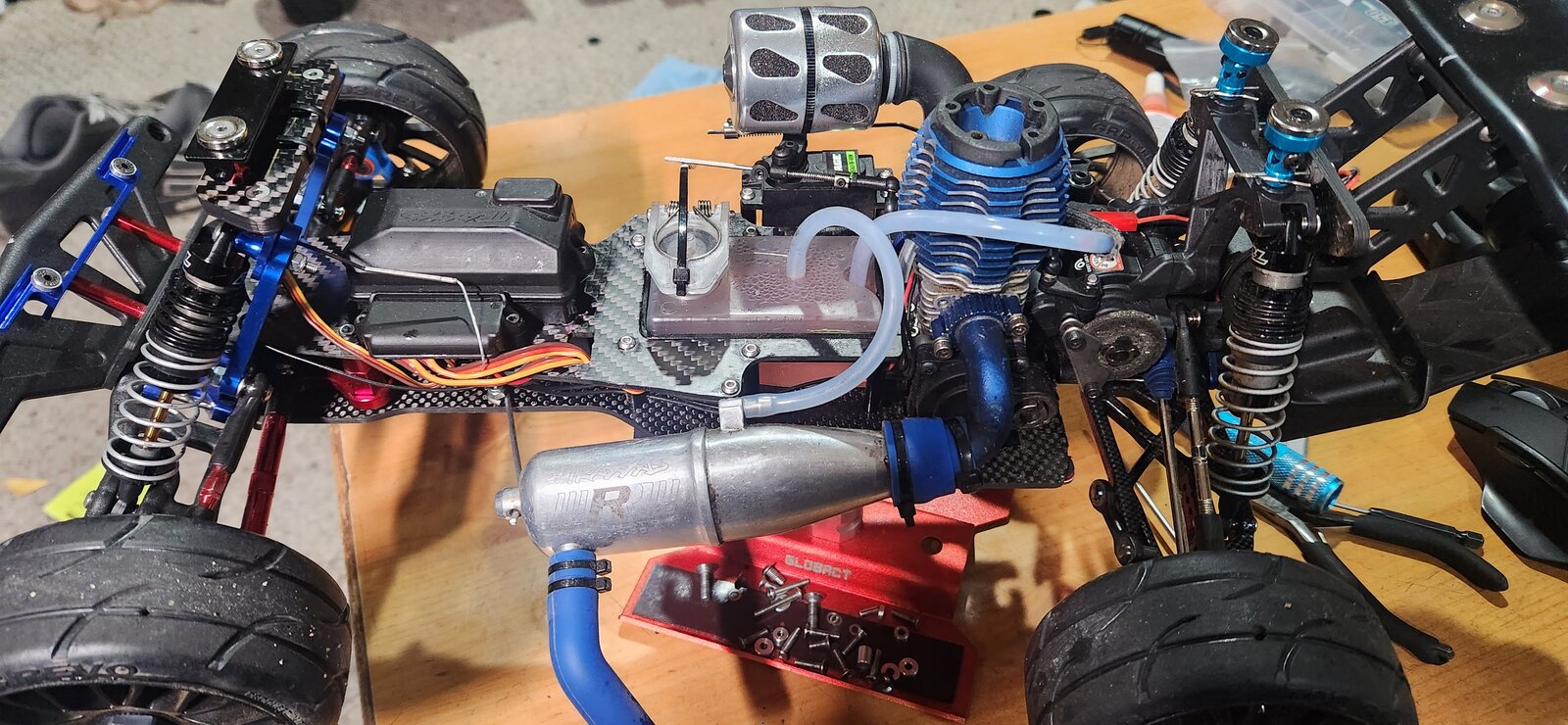

My local RC shop had 1 OS 11k 18TM carb still in stock, yes they still had 1. I didn't need it but I knew how hard they were to find because of COVID and they were backordered I decided to buy it. I took the 2.5r that was swapped out with the power up program and dropped in a 3.3 crank with the OS 11K carb. Doing that woke up the motor something fierce.

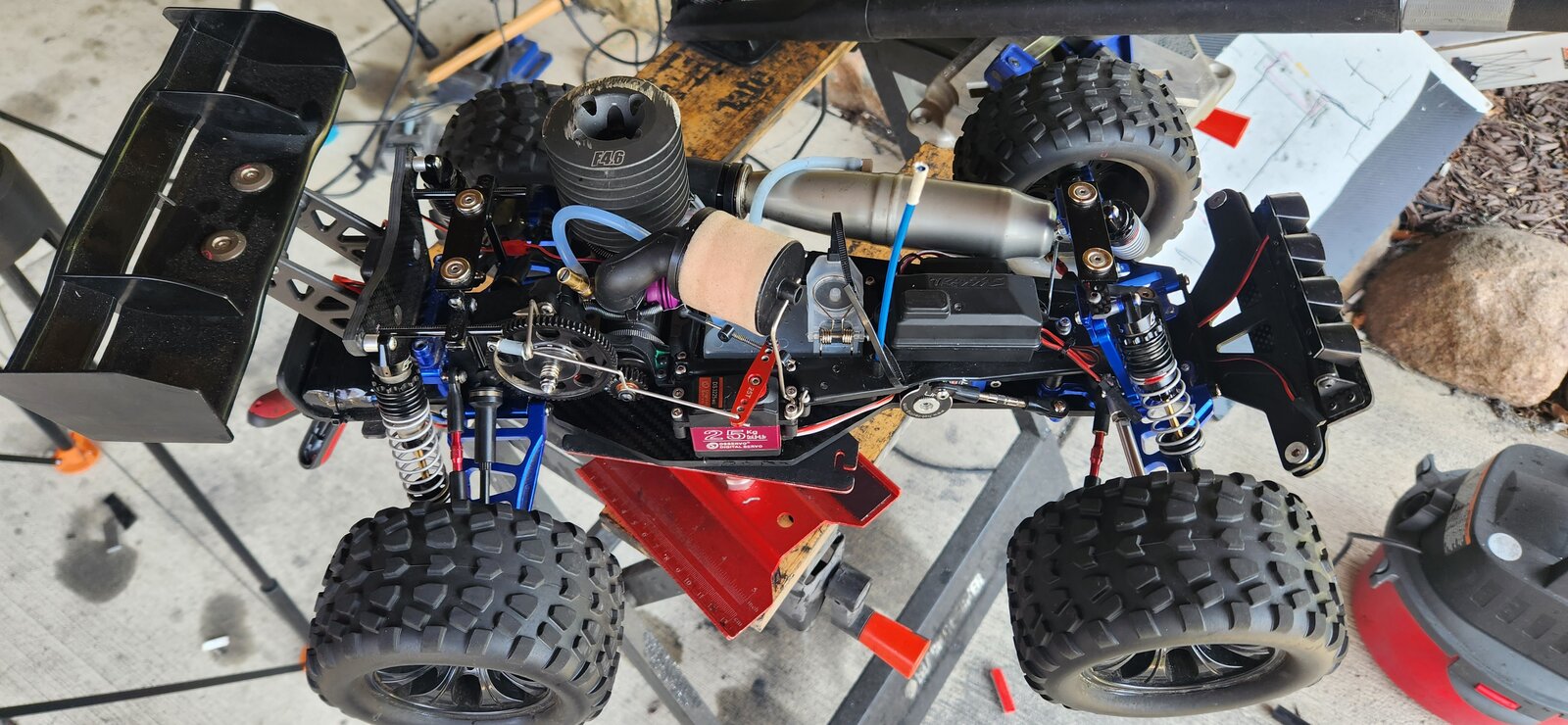

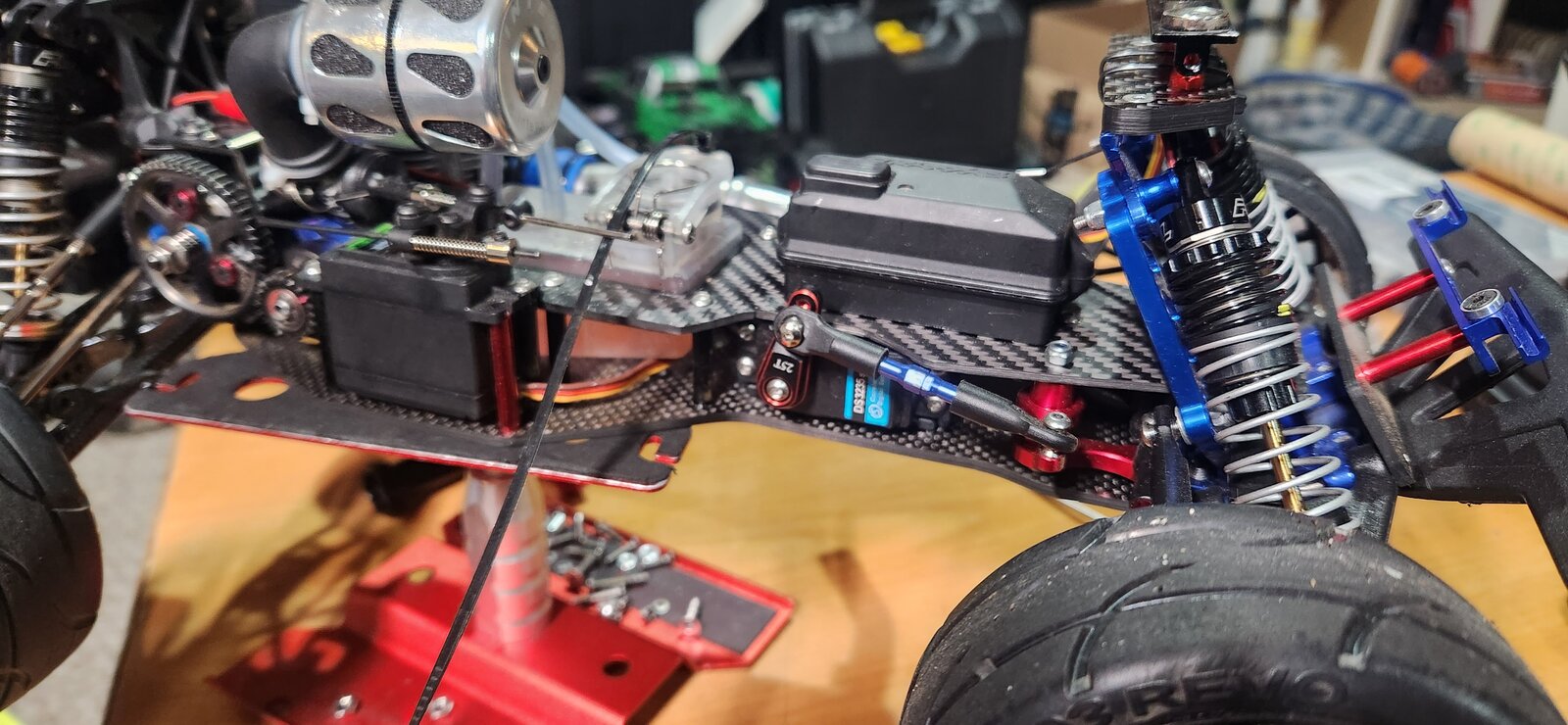

After that I decided to think about what I could do to take this build over the top. I started looking for a Jato 2 speed. I found a brand new one off Ebay for $100. Along with the 2 speed I started thinking what else I'd need to make it work with the Rustler. I knew I'd need a custom chassis plate so it ended up making things easier. I bought an engine mount, throttle/brake linkages, brake parts, shock tower, control arms, drive shafts, caster blocks, suspension links, wheelie bar and battery box for a Jato. Basically everything from the motor mount and back is from a Jato. I also decided to drop in the Hot Racing Jato 2 speed steel gear set.

The wing is off a Losi 8ight I mounted to the shock tower with a custom cut carbon fiber plate

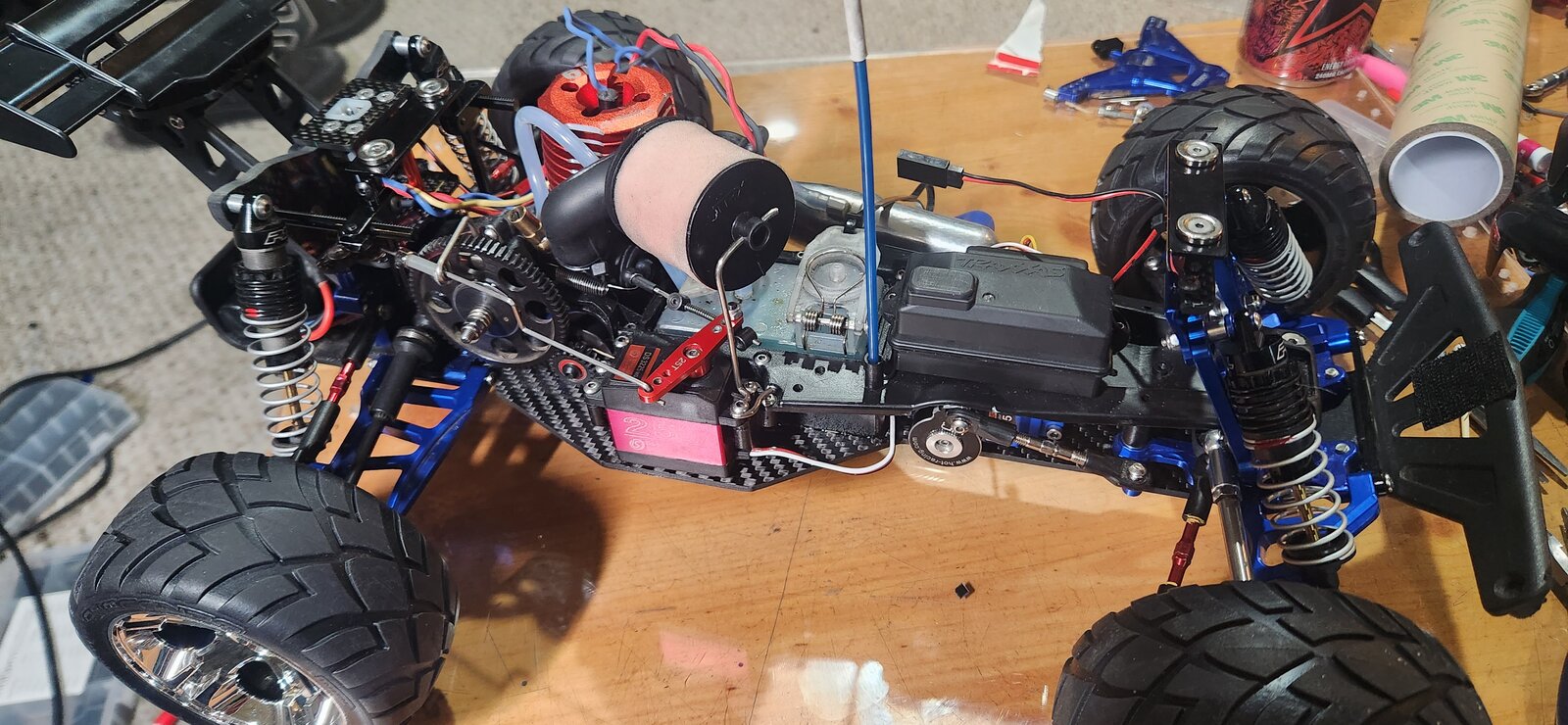

I'm using RPM control arms, caster blocks and steering blocks off a 2wd electric slash.

I did a MIP 12mm to 17mm hex conversion from a Rustler, but I did need smaller front axles so I used some from a bandit.

Proline shocks all the way around.

I've got the front brackets for the sway bars but I haven't found a way to stabilize it yet so that's taken the backseat for now and I removed the sway bars.

This weekend I will be fitting a Jato body on it it getting rid of the magnet mounts. Last night I got it to hit 45 according to the GPS sensor but I know the Jato is rated for 65+. I've got a 20T clutch bell and a 54T spur gear. Even though it has a 2.5r in it, it should be able to come close to that because from what I've seen the main difference between the 3.3 and 2.5 is the crank. The piston and connecting rod are the same so it's basically a 3.3 in a 2.5 block. Well that's what I've seen/heard and I could be completely wrong.

Some background:

This was my first nitro RC. I've been working on cars all my life but my background is IT and Engineering. I got the stadium truck from my dad. He bought it probably close to 15 years ago. He did the break in and started tuning the carb and the throttle hung and it met a curb. He put it in a box and that's where it laid until I asked him about it this past March. He gave me everything he had for it. When he hit the curb he broke the upper chassis deck which cost me $10 from our local RC shop. While I was there I decided to do the power up program and swap the old receiver and transmitter with a new TQI one and add a full waterproof receiver box.

It took me a couple of hors of cleaning out the carb with brake cleaner and q tips before it'd slide like butter.

Next was the motor. I knew it was seized because I couldn't move it by hand at all. I took the glow plug out and added a couple of drops of 5w30 in the head. I 3d printed an adapter for the one way bearing with a 17mm hex on it so I could spin the motor with a ratchet. I heated up the block with a heat gun and tried to wiggle the crank back and forth. I sprayed some WD40 to try and break down the rust. very slowly did it start to move until eventually I heard a metallic click and the crank moved freely. I used the ratchet until my hand got tired and put the 17mm on my 1/4" impact. Added some more 5w30 and spun the motor very slowly. After a couple of minutes I'd spin faster and faster until the impact was full speed. Slapped it all back together and the damn thing ran.

I bought a HPI Savage X. The Rustler took the back seat for a while but I did swap the 2.5r out for another 2.5r using the power up program. But I decided to do something completely ridiculous with my rustler. First I decided to put a HPI 4.6 big block in it. Nowhere near practical but honestly I wanted to see if it'd work. I had to cut a custom carbon fiber chassis plate. I did this in my backyard with a dremel, a drill press and the original chassis plate as a template. The aluminum parts in the picture are from Integy and are actually from a Rustler VXL.

I took the 4.6 out and put it in my Revo and slapped my Dynamite 19 back in the rustler but I wanted more out of it.

My local RC shop had 1 OS 11k 18TM carb still in stock, yes they still had 1. I didn't need it but I knew how hard they were to find because of COVID and they were backordered I decided to buy it. I took the 2.5r that was swapped out with the power up program and dropped in a 3.3 crank with the OS 11K carb. Doing that woke up the motor something fierce.

After that I decided to think about what I could do to take this build over the top. I started looking for a Jato 2 speed. I found a brand new one off Ebay for $100. Along with the 2 speed I started thinking what else I'd need to make it work with the Rustler. I knew I'd need a custom chassis plate so it ended up making things easier. I bought an engine mount, throttle/brake linkages, brake parts, shock tower, control arms, drive shafts, caster blocks, suspension links, wheelie bar and battery box for a Jato. Basically everything from the motor mount and back is from a Jato. I also decided to drop in the Hot Racing Jato 2 speed steel gear set.

The wing is off a Losi 8ight I mounted to the shock tower with a custom cut carbon fiber plate

I'm using RPM control arms, caster blocks and steering blocks off a 2wd electric slash.

I did a MIP 12mm to 17mm hex conversion from a Rustler, but I did need smaller front axles so I used some from a bandit.

Proline shocks all the way around.

I've got the front brackets for the sway bars but I haven't found a way to stabilize it yet so that's taken the backseat for now and I removed the sway bars.

This weekend I will be fitting a Jato body on it it getting rid of the magnet mounts. Last night I got it to hit 45 according to the GPS sensor but I know the Jato is rated for 65+. I've got a 20T clutch bell and a 54T spur gear. Even though it has a 2.5r in it, it should be able to come close to that because from what I've seen the main difference between the 3.3 and 2.5 is the crank. The piston and connecting rod are the same so it's basically a 3.3 in a 2.5 block. Well that's what I've seen/heard and I could be completely wrong.