Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

More options

Who Replied?WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,809

- Reaction score

- 20,903

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

Did you try the oven method mentioned?struggling to get the piston sleeve out...

STONER RC

BUILD it, SEND it, BASH it, FIX it, REPEAT

Lifetime Supporter!

Supporter

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 4,429

- Reaction score

- 3,862

- Location

- Brick, New Jersey

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

- Flying

- Boating

Did you happen to get out your sleeve? If not you can try freeze off. It's a blue and white can thats at any auto parts place. It should shrink the part enough to get it out. With a little pressure.

WideOpen

RCTalk Addict

Supporter

- Thread starter

- #45

been a busy day, did my civil parade duty then made it to HobbyTown and spent $100 then came home and changed the fuel filter and hoses on my tractor, then cut grass. I did take the truck and controller to HobbyTown and the guy behind the counter said "wrong controller" for the little gizmo. Somewhere in all my busy, I found the controller he said to look for, and whalla - it communicated! Now I just have to get that stupid piston sleeve out.

WideOpen

RCTalk Addict

Supporter

- Thread starter

- #47

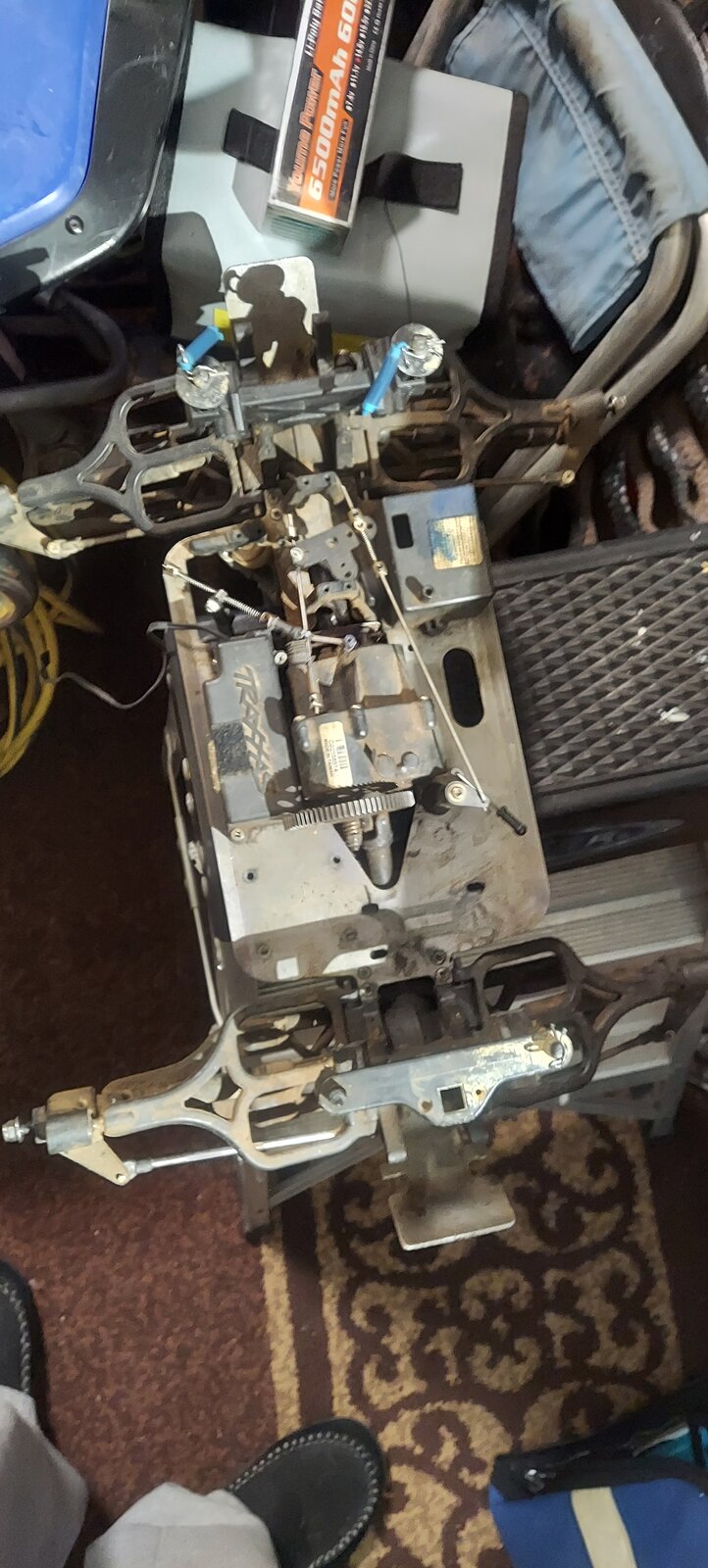

Still have not been able to remove the cylinder sleeve - it is a booger. However I began messing with the communications part of it a little more today. That boy of mine had this set up kinda screwy - this is about a 2006 TMaxx Classic 2.5 - can someone shoot me a picture of the bottom of what this machine should look like? He had the pinion arm positioned incorrectly and I am wondering about other things - heck I'd guess I'd also like a picture of the top side of the chassis works too.

- Messages

- 9,190

- Reaction score

- 16,401

- Location

- Central California

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

- Flying

Success! Glad to hear you finally got it.

STONER RC

BUILD it, SEND it, BASH it, FIX it, REPEAT

Lifetime Supporter!

Supporter

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 4,429

- Reaction score

- 3,862

- Location

- Brick, New Jersey

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

- Flying

- Boating

Here you go bud Tmaxx 2.5 nitro underStill have not been able to remove the cylinder sleeve - it is a booger. However I began messing with the communications part of it a little more today. That boy of mine had this set up kinda screwy - this is about a 2006 TMaxx Classic 2.5 - can someone shoot me a picture of the bottom of what this machine should look like? He had the pinion arm positioned incorrectly and I am wondering about other things - heck I'd guess I'd also like a picture of the top side of the chassis works too.

And top veiw

Attachments

STONER RC

BUILD it, SEND it, BASH it, FIX it, REPEAT

Lifetime Supporter!

Supporter

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 4,429

- Reaction score

- 3,862

- Location

- Brick, New Jersey

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

- Flying

- Boating

Sorry it looks like crap. My 2.5 is actually torn down to basically just the trans and drive train.I threw the motor and steering servo in this morning for the pics. This is what it really looks like. LoLIf you need the exploded veiws paper work. I can send that to you as well.just let me know bud

STONER RC

BUILD it, SEND it, BASH it, FIX it, REPEAT

Lifetime Supporter!

Supporter

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 4,429

- Reaction score

- 3,862

- Location

- Brick, New Jersey

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

- Flying

- Boating

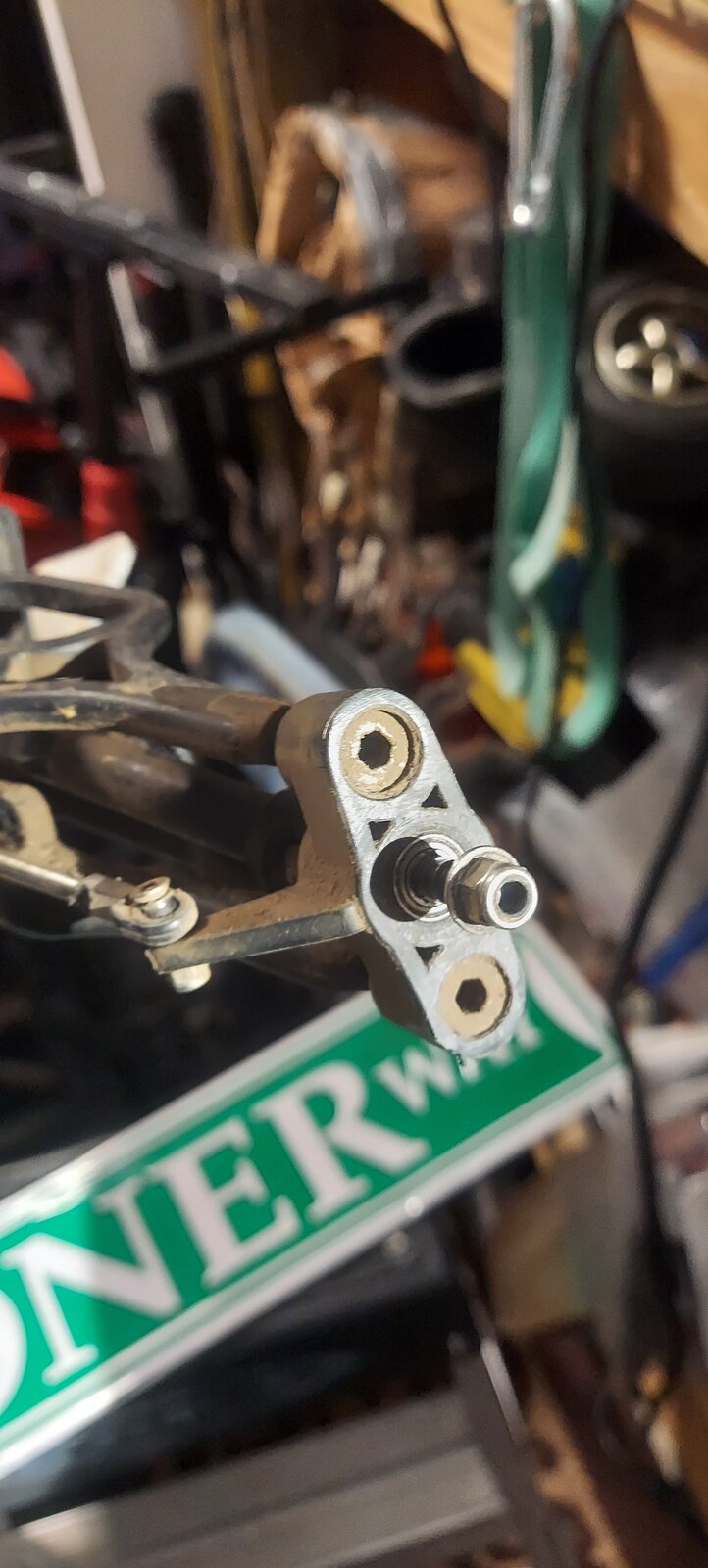

Are you taking about the ball cap screws. That are counter sunk into the knuckles depending how much camber you have on your wheels?

STONER RC

BUILD it, SEND it, BASH it, FIX it, REPEAT

Lifetime Supporter!

Supporter

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 4,429

- Reaction score

- 3,862

- Location

- Brick, New Jersey

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

- Flying

- Boating

Or you talking about the tie rod end screw that is also a counter sunk to set into the tie rod end?

I believe hes talking about the screw holding the tie rod ball end to the pillow ball hub. If so then it doesn't really matter what the screw head is as long as it doesn't hit or interfere with normal operation. Thats actually true of any screw anywhere on the kit....Unless your OCD like me and you want everything exactly like the manual says lol.Are you taking about the ball cap screws. That are counter sunk into the knuckles depending how much camber you have on your wheels?

View attachment 129118

STONER RC

BUILD it, SEND it, BASH it, FIX it, REPEAT

Lifetime Supporter!

Supporter

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 4,429

- Reaction score

- 3,862

- Location

- Brick, New Jersey

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

- Flying

- Boating

It definitely doesn't matter. Use what ever screw you have that will fit. And not interfere like you Wolf said. LOL

STONER RC

BUILD it, SEND it, BASH it, FIX it, REPEAT

Lifetime Supporter!

Supporter

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 4,429

- Reaction score

- 3,862

- Location

- Brick, New Jersey

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

- Flying

- Boating

Did you try taken the easy start off the motor and putting a wrench on the one way bearing. And try and turn it. Do you have a vice to put it and hold it. If it's gummed up you also could try to heat up the caseing see if you can get the gummed fuel loosened up a little to turn itEngine is locked up. I have it pulled,

The nearest HobbyTown is 40 minutes away and they don't open until I get to work and they close too early after I get off of work - well, I could make it, it'd just be fighting traffic and rushing.

- Is the backplate the plate directly under where the exhaust comes out?

- Will there be gaskets in there that I will need to replace?

- Is there something else I can soak this in beside the after run oil?

WideOpen

RCTalk Addict

Supporter

- Thread starter

- #60

That - that just don't seem logical to meI believe hes talking about the screw holding the tie rod ball end to the pillow ball hub. If so then it doesn't really matter what the screw head is as long as it doesn't hit or interfere with normal operation. Thats actually true of any screw anywhere on the kit....Unless your OCD like me and you want everything exactly like the manual says lol.

View attachment 129120