gandalfnz

RCTalk Addict

- Thread starter

- #161

Hello

Ok, here's the feedback so far.

Clutch has held up quite well and works good, but after a few runs I have noticed that already clutch spring is starting to wear due to touching the clutch bell. Those clutches are crap from the factory, as the spring is not sunk in enough, and is almost in line with the top surface of the clutch shoe and sticks out. Hard to understand why they manufactured it like this. I have replaced it with the same half/half clutch but aluminum this time, as I don't have any other.

Brake disk was rubbing quite a lot on the flywheel and I had issues tuning because of it, so I sanded it down and made the diameter smaller so it clears the flywheel, to my surprise, the car still brakes really good, I can't see the difference.

I also installed a clutch bell with higher tooth count, so it should be faster now as well.

So many changes went into this car lately, I can't wait to test it and see how it holds up.

@tudordewolf

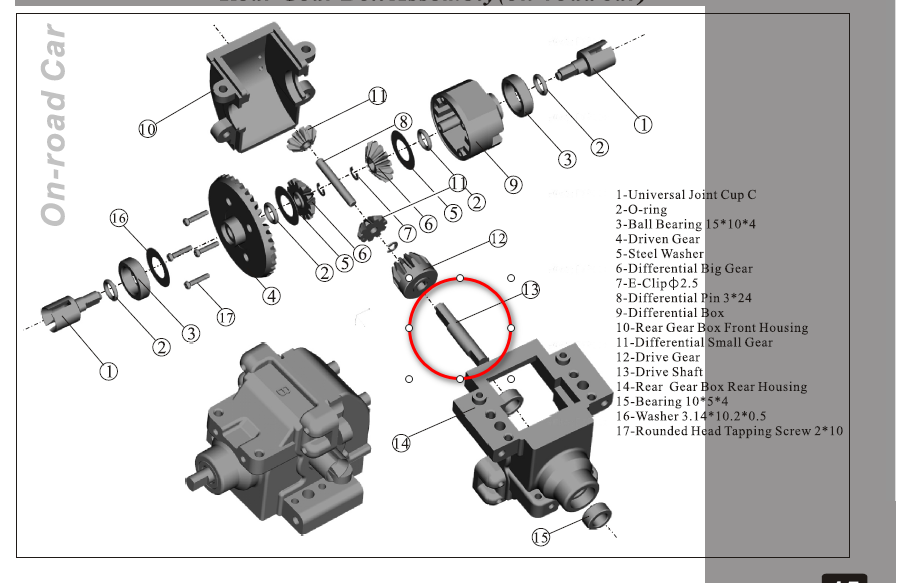

While taking the car apart I noticed that my driveshaft (as per pic) is quite worn, due to grub screw not being tight.

However, am I having issues locating this spare part?

Ok, here's the feedback so far.

Clutch has held up quite well and works good, but after a few runs I have noticed that already clutch spring is starting to wear due to touching the clutch bell. Those clutches are crap from the factory, as the spring is not sunk in enough, and is almost in line with the top surface of the clutch shoe and sticks out. Hard to understand why they manufactured it like this. I have replaced it with the same half/half clutch but aluminum this time, as I don't have any other.

Brake disk was rubbing quite a lot on the flywheel and I had issues tuning because of it, so I sanded it down and made the diameter smaller so it clears the flywheel, to my surprise, the car still brakes really good, I can't see the difference.

I also installed a clutch bell with higher tooth count, so it should be faster now as well.

So many changes went into this car lately, I can't wait to test it and see how it holds up.

@tudordewolf

While taking the car apart I noticed that my driveshaft (as per pic) is quite worn, due to grub screw not being tight.

However, am I having issues locating this spare part?