gandalfnz

RCTalk Addict

- Thread starter

- #21

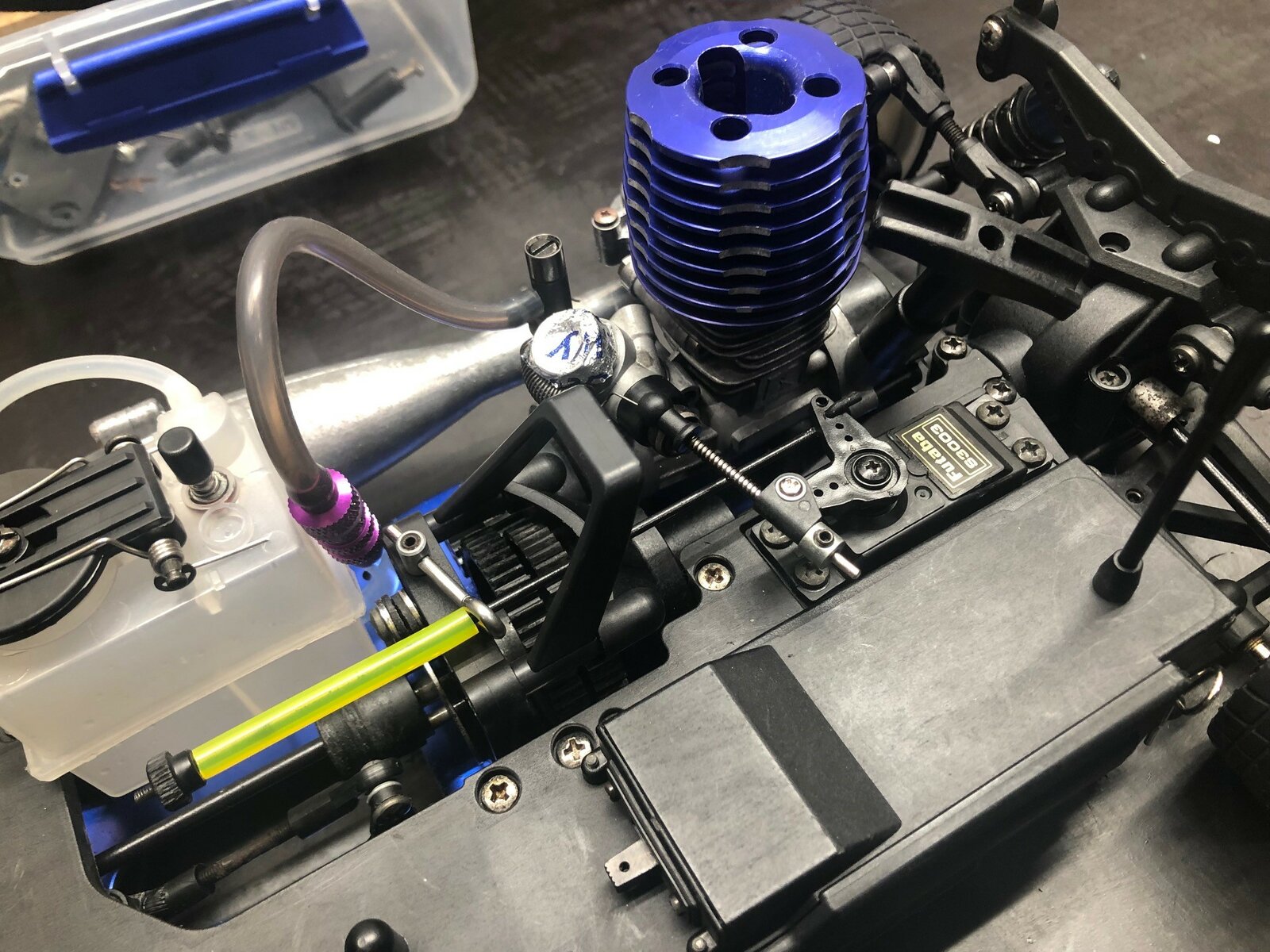

Almost there, FW05 is 90% finished, need to drill new engine mounts on the chassis.

Waiting on a front bumper set from Japan.

Throttle linkage on original setup was for a rotary carb, rotated the servo by 180 and few minor changes, works really well.

Waiting on a front bumper set from Japan.

Throttle linkage on original setup was for a rotary carb, rotated the servo by 180 and few minor changes, works really well.