My first parts are in from Tekno. Despite the roller coaster ride of whether to designate it to a parts expense and buy a new kit, I've opted to do what I originally planned with it.

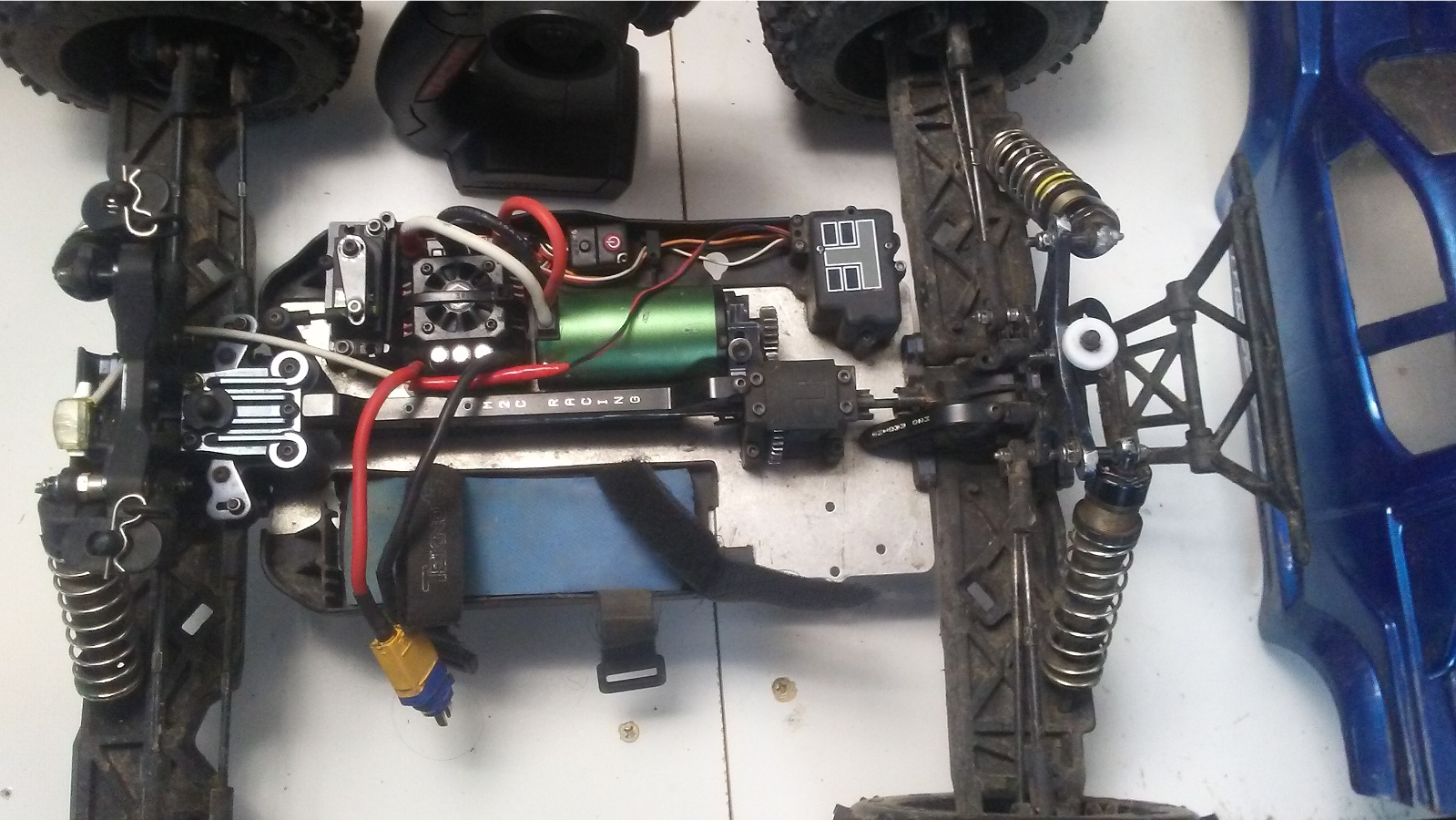

Please excuse the poor quality camera from my cheap smartphone. The radio was added as the original only came with a receiver. I have had a couple of runs in wettish conditions so there is a bit of dirt. Overall it look pretty good.

The battery adapter is a band-aid that my good friend Nick put on to run an extra pair of 2S packs he has until my batteries arrive.

At some point I'll need to do something about the spring combination, there is a Green in front and a Yellow in back. I haven't yet verified if the shocks are fit front to back; the tekno manual has the 137mm in the rear and I think on my rig they my be up front.

Goodies from Tekno. Mostly parts associated with the installation of the sway bars, which I want. I may delay installing them for now, we'll see. Does anyone have a comment about whether they are needed?

The front SCT bumper was highly recommended by Nick as I am an RC beginner. My intention is also to let my 6 year old girl drive the rig; bumpers are a good thing to have. I personally like the look of the A Block cover/bumper.

The rear diff gearbox is here because we identified a broken part.

Nick drilled a deeper hole and installed a longer screw as a temporary measure.

This is the state of my MT410 mostly as it was purchased. Of course Nick put a bit of time going over everything and bringing it back to Tekno recommended initial setup.

Right now the truck will move but I'm waiting for the new Jx Pdi-6221mg 20kg Large Torque Digital Coreless Servo. I stripped the gears on the Rage server depicted above when I splashed it though a puddle of water, and after the electronics went haywire. I fixed that by drying back all the water I could find on the electronics. Because Nick and I sometimes do some night-time driving there is a light up front so I can track where and which direction the truck is going.

If you want to see more progress with my MT410 RC repairs and other things do like this post so that I know the extra time posting is worth the efforts.

Please excuse the poor quality camera from my cheap smartphone. The radio was added as the original only came with a receiver. I have had a couple of runs in wettish conditions so there is a bit of dirt. Overall it look pretty good.

The battery adapter is a band-aid that my good friend Nick put on to run an extra pair of 2S packs he has until my batteries arrive.

At some point I'll need to do something about the spring combination, there is a Green in front and a Yellow in back. I haven't yet verified if the shocks are fit front to back; the tekno manual has the 137mm in the rear and I think on my rig they my be up front.

Goodies from Tekno. Mostly parts associated with the installation of the sway bars, which I want. I may delay installing them for now, we'll see. Does anyone have a comment about whether they are needed?

The front SCT bumper was highly recommended by Nick as I am an RC beginner. My intention is also to let my 6 year old girl drive the rig; bumpers are a good thing to have. I personally like the look of the A Block cover/bumper.

The rear diff gearbox is here because we identified a broken part.

Nick drilled a deeper hole and installed a longer screw as a temporary measure.

This is the state of my MT410 mostly as it was purchased. Of course Nick put a bit of time going over everything and bringing it back to Tekno recommended initial setup.

Right now the truck will move but I'm waiting for the new Jx Pdi-6221mg 20kg Large Torque Digital Coreless Servo. I stripped the gears on the Rage server depicted above when I splashed it though a puddle of water, and after the electronics went haywire. I fixed that by drying back all the water I could find on the electronics. Because Nick and I sometimes do some night-time driving there is a light up front so I can track where and which direction the truck is going.

If you want to see more progress with my MT410 RC repairs and other things do like this post so that I know the extra time posting is worth the efforts.