STONER RC

BUILD it, SEND it, BASH it, FIX it, REPEAT

Lifetime Supporter!

Supporter

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 4,429

- Reaction score

- 3,862

- Location

- Brick, New Jersey

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

- Flying

- Boating

Nice save dad!!Hmmquite a bit actually lol. From installing a diff backwards to forgetting screws to diff cases that then took a good 20 mins to tear the rig back apart and install the screws. Also have sent rigs at my face numerous times and thankfully was able to high five them out of the way or side step and just get missed

here's one, I almost took my Bigrock to the face but high fived it to stop it. Couldn't move as my daughter was standing directly behind me a couple feet so if I moved it would have taken her out

if you look at the end of the video you'll see her shadow standing right behind me.

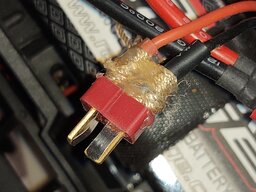

pre brushless lithium explosion circa 2008

my first go with a conversion of a Nitro to Brushless using a 4074 2000kv inrunner motor intended for large air , a 4s 4000mah 30c soft pack also intended for sky, and the original HobbyWing xerun 150 esc, original flysky 2ch 2.4 radio.

The metal beast Nitro Quake full running weight of 14 pounds...

I'm holding the truck in my arms while buttoning up the final touches for initial run, and derp der here switches on the truck first...

Luckily one of the center output cups grub screw sheered quickly, otherwise id have needed skin grafts on my entire left arm and chest...

Lol

Oh yes the good Ole rc tire tatoo.. I've had that one before. Pretty sure most of the guys here have had that tattoo..I once accidentally did a burnout with my Typhon on my leg, I was testing to see if it hit LVC or not and the gyroscopic force of it brought it to my knee...