Though this is technically not a 3D printer, a CNC is similar in how designs are created, but the opposite in how parts are made because you cut away material instead.

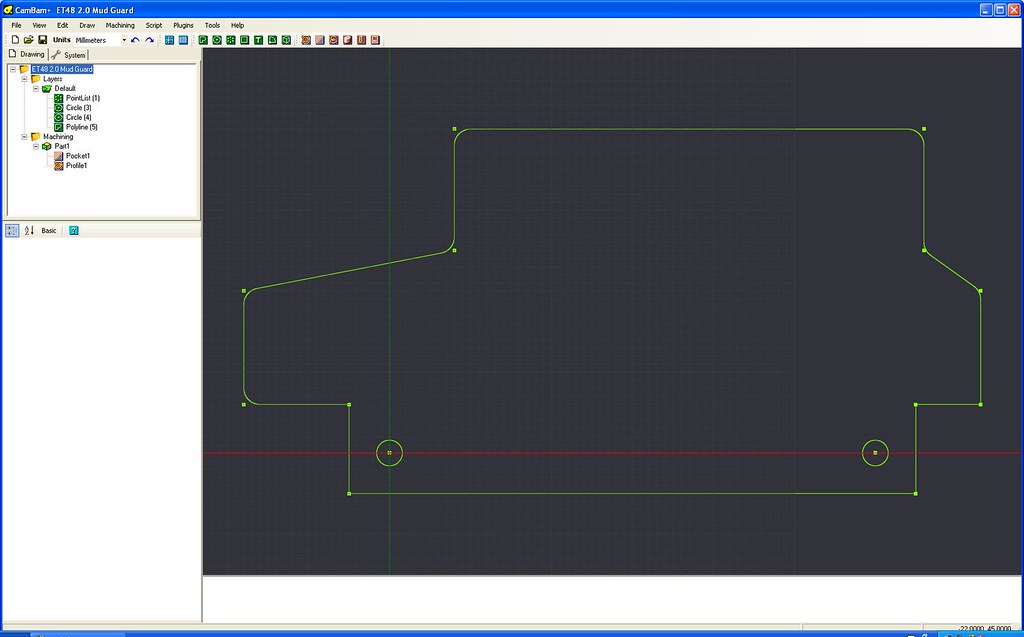

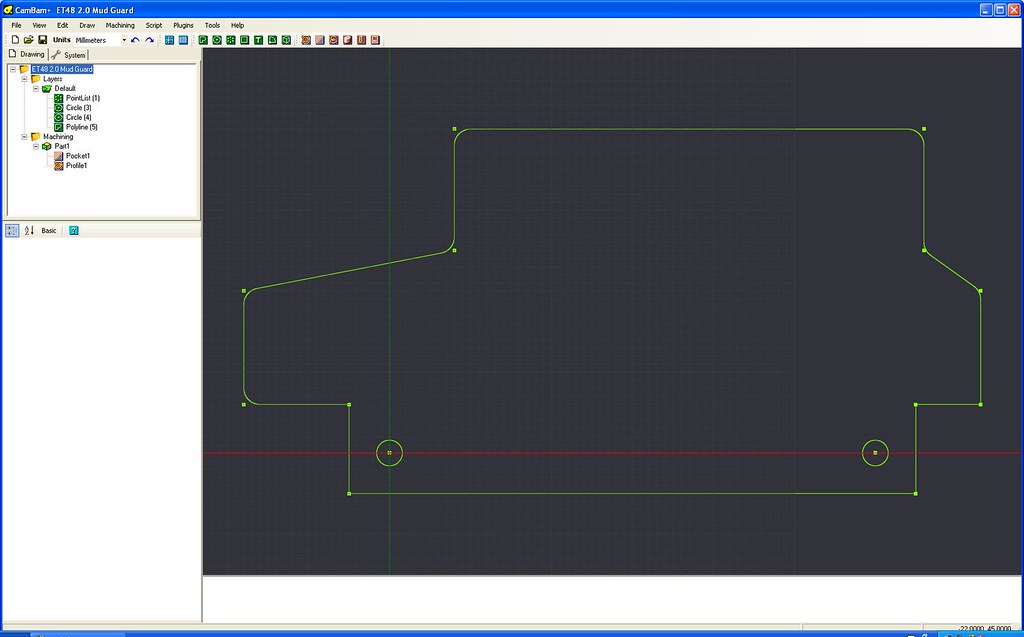

It's hard to believe that my CNC is approaching 10 years old... I just pulled it out of storage this week as someone hit me up to design some new mud guards for their TEKNO ET48 2.0 truggy, he sent me the measurements of the hole spacing and this is what I came up with:

I based the design off an existing point list I used in the past for the SCT410.3 and EB48 2.0 designs I made many years ago.

For those interested in seeing my CNC, here's what it looked like out of the box:

The CNC came with a fully licensed copy of Mach3 which accepts G-Code from any CAM based product for the tooling:

https://www.machsupport.com/software/mach3

After trying several different CAD programs, I decided to go with CamBam which integrates the CAD drawings and generate tool paths for the G-Code in the same program making the best combination between low cost and ease of use that I found at the time. I continue to use the same product today!

http://www.cambam.info/

I've milled many parts over the years ranging from Kydex to Carbon Fiber as well as Aluminum!

I will only mill aluminum if I'm desperate, it takes a lot of effort to manually oil the cutting bit and it's hard on the spindle which tends to need replacement every 8 hours of cutting aluminum where Kydex and Carbon Fiber can go many years before I have to replace a spindle cutting those materials.

I no longer have a 3D printer as I have found the quality of the parts I've milled with my CNC to be far superior, though I may invest in another 3D printer again someday as my CNC is limited to 2.5D cuts.

It's hard to believe that my CNC is approaching 10 years old... I just pulled it out of storage this week as someone hit me up to design some new mud guards for their TEKNO ET48 2.0 truggy, he sent me the measurements of the hole spacing and this is what I came up with:

I based the design off an existing point list I used in the past for the SCT410.3 and EB48 2.0 designs I made many years ago.

For those interested in seeing my CNC, here's what it looked like out of the box:

The CNC came with a fully licensed copy of Mach3 which accepts G-Code from any CAM based product for the tooling:

https://www.machsupport.com/software/mach3

After trying several different CAD programs, I decided to go with CamBam which integrates the CAD drawings and generate tool paths for the G-Code in the same program making the best combination between low cost and ease of use that I found at the time. I continue to use the same product today!

http://www.cambam.info/

I've milled many parts over the years ranging from Kydex to Carbon Fiber as well as Aluminum!

I will only mill aluminum if I'm desperate, it takes a lot of effort to manually oil the cutting bit and it's hard on the spindle which tends to need replacement every 8 hours of cutting aluminum where Kydex and Carbon Fiber can go many years before I have to replace a spindle cutting those materials.

I no longer have a 3D printer as I have found the quality of the parts I've milled with my CNC to be far superior, though I may invest in another 3D printer again someday as my CNC is limited to 2.5D cuts.