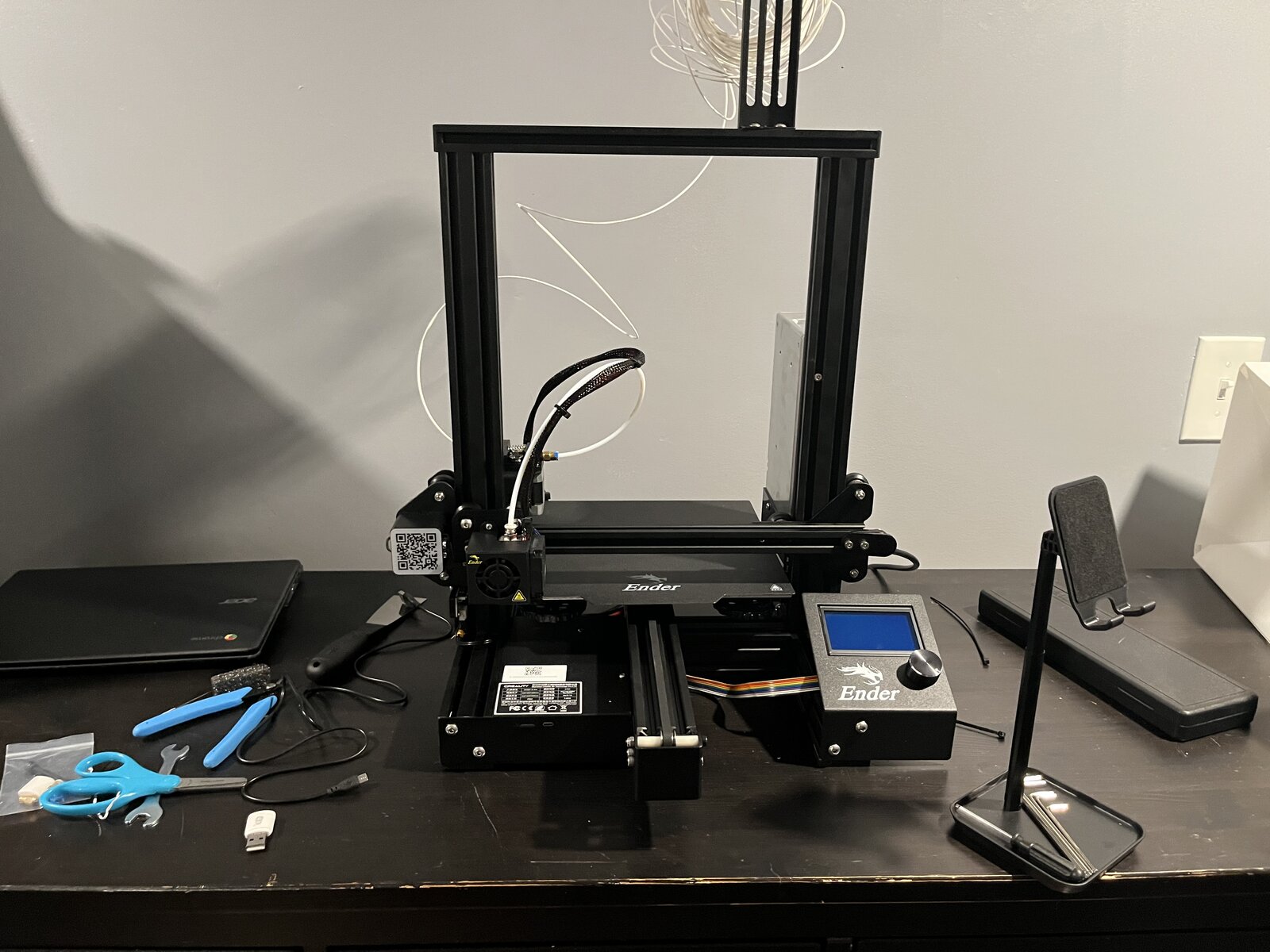

Damn does this thing look sick got it yesterday assembled it and printed a gear came out like crap (it was not a good design it’s was for testing) going to print some Jerry cans today also might be getting a 1/10 crawler this week enless I pick something different

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

More options

Who Replied?- Messages

- 170

- Reaction score

- 165

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

I got got a 3d printer yesterday too.

- Messages

- 540

- Reaction score

- 889

- Location

- Western Washington

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

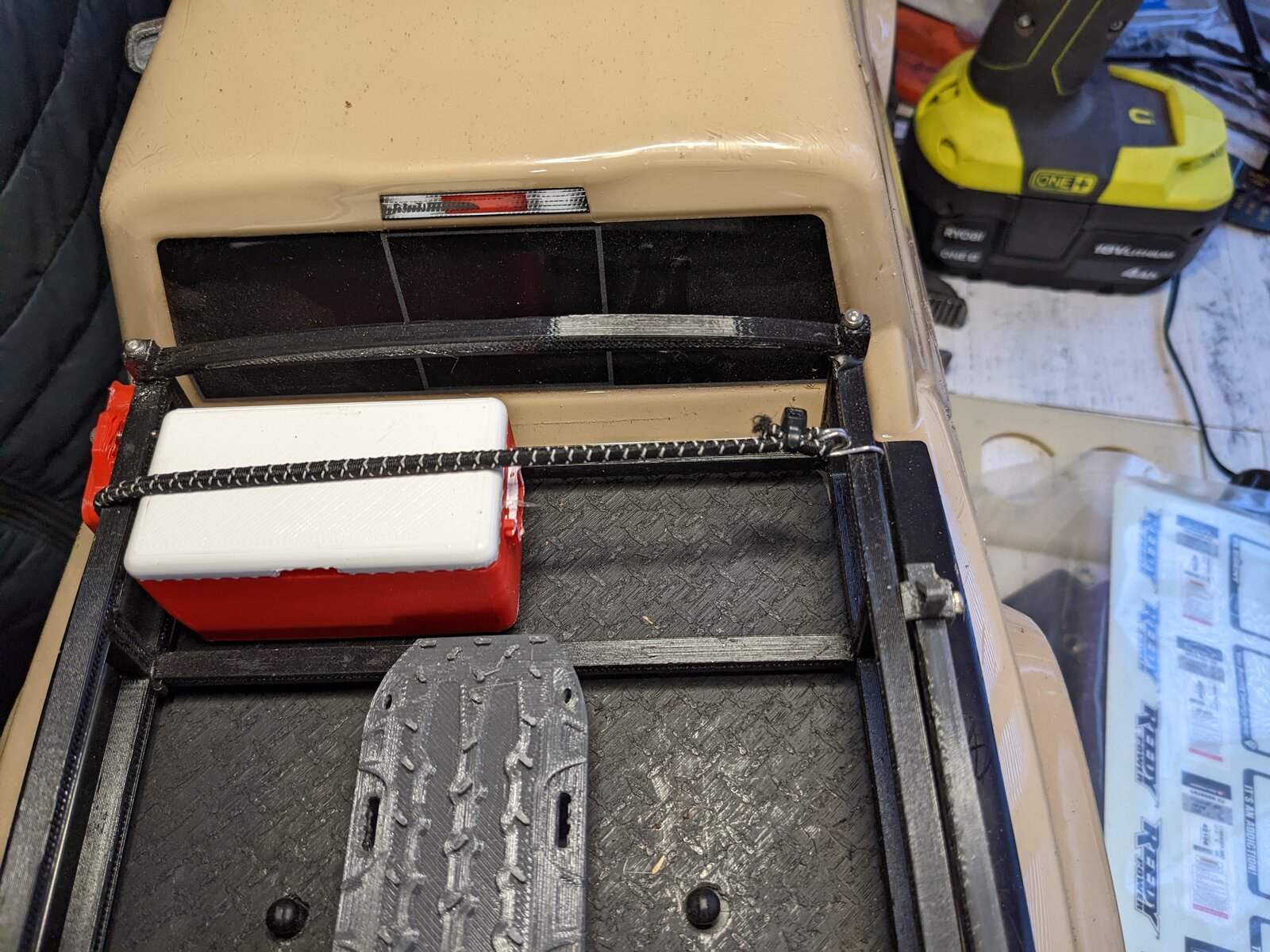

This is the way.

Front and rear bumpers, bumper lights, beadlocks, hub nut covers, bed rack, Gerry cans, jack, cooler, forward mount servo relocate, LCG battery tray, and a couple other accessories for it all 3d printed.

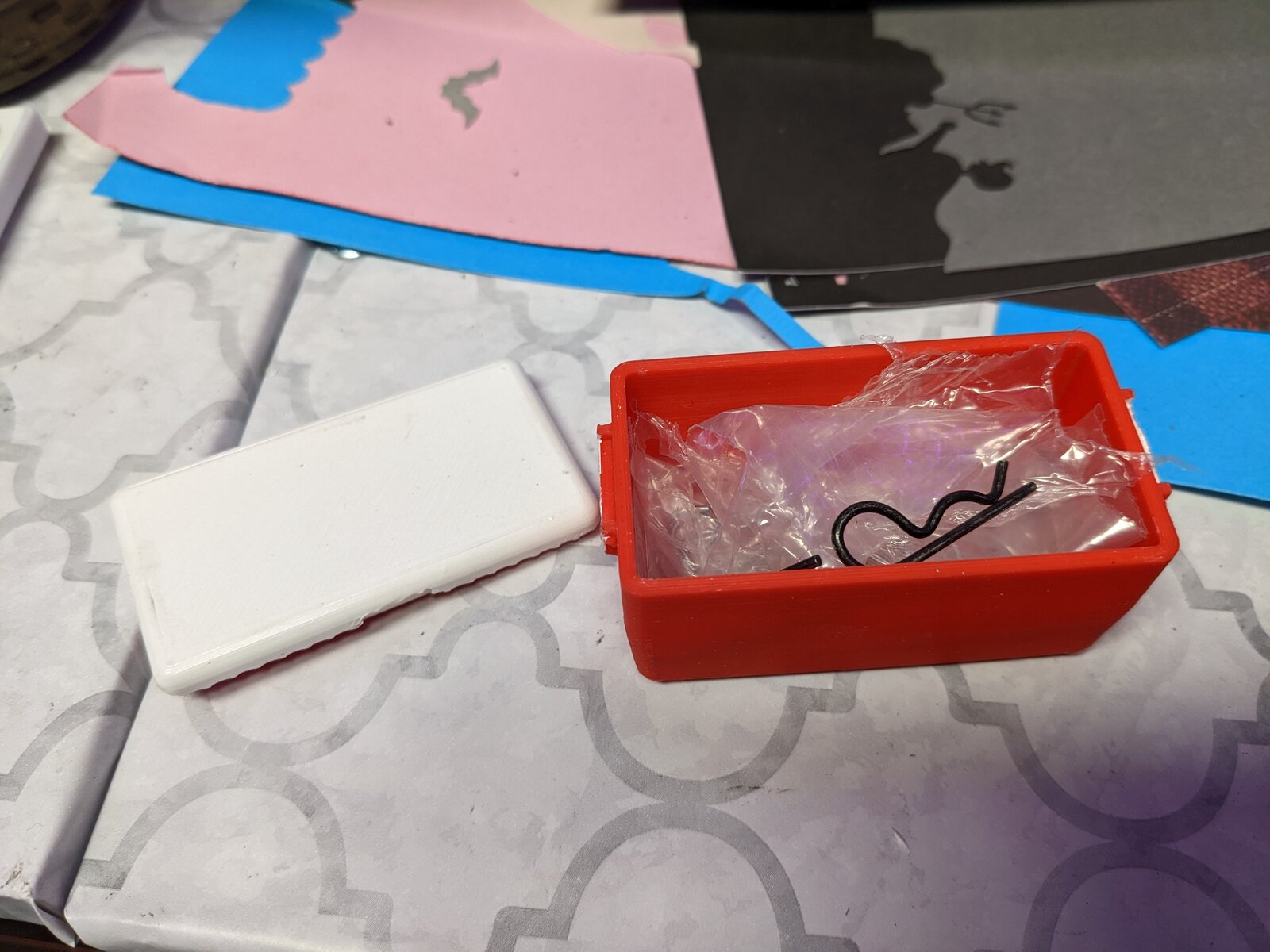

I like to have some function too. This cooler also doubles as storage for my body clips, extra body clips, and extra hub nuts.

Front and rear bumpers, bumper lights, beadlocks, hub nut covers, bed rack, Gerry cans, jack, cooler, forward mount servo relocate, LCG battery tray, and a couple other accessories for it all 3d printed.

I like to have some function too. This cooler also doubles as storage for my body clips, extra body clips, and extra hub nuts.

2wdMod

RCTalk Talkaholic

Nice Dude!! now for the next 6 months of learning curve as you encounter problems,LOL

- Thread starter

- #5

Nice I will ask you some questions because I bought a sport todayThis is the way.

Front and rear bumpers, bumper lights, beadlocks, hub nut covers, bed rack, Gerry cans, jack, cooler, forward mount servo relocate, LCG battery tray, and a couple other accessories for it all 3d printed.

View attachment 157340View attachment 157341View attachment 157342View attachment 157343

I like to have some function too. This cooler also doubles as storage for my body clips, extra body clips, and extra hub nuts.

View attachment 157344View attachment 157345

Nice Dude!! now for the next 6 months of learning curve as you encounter problems,LOL

That is no joke. I almost threw my first one in the trash I got so frustrated with it in the beginning.Nice Dude!! now for the next 6 months of learning curve as you encounter problems,LOL

- Thread starter

- #7

Same here this thing printed for 1 hours did a little bit of a gas can and stopped printing only have been trying to get it to print something for 7 hoursThat is no joke. I almost threw my first one in the trash I got so frustrated with it in the beginning.

WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,924

- Reaction score

- 21,117

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

They can be frustrating. What are your print settings? Temps, layer height, outer perimeters, top and bottom layers, etc? And what filament are you using?

2wdMod

RCTalk Talkaholic

I have been a machinist for most of my life, I put getting a printer off until about 3 yrs ago .. I was intimidated by learning something new.. After I jumped in I actually was surprised as to how simple it really is.. Mainly I was intimidated by my own experience.. If I crash a mill with a .750" carbide end mill in it , thats a $75 crash minimum if it only takes out the tool.. Then theres the cost of the part that most likely was ruined in the crash.. So yeah to set up a machine that the worst things that happens when you "crash" it is you might scratch the build plate was both refreshing ,and a little underwhelming.. LOLThat is no joke. I almost threw my first one in the trash I got so frustrated with it in the beginning.

WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,924

- Reaction score

- 21,117

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

Shoot, I saw crashes costing tens of thousands of dollars. When a 3d printer crashes, it just goes click click clickI have been a machinist for most of my life, I put getting a printer off until about 3 yrs ago .. I was intimidated by learning something new.. After I jumped in I actually was surprised as to how simple it really is.. Mainly I was intimidated by my own experience.. If I crash a mill with a .750" carbide end mill in it , thats a $75 crash minimum if it only takes out the tool.. Then theres the cost of the part that most likely was ruined in the crash.. So yeah to set up a machine that the worst things that happens when you "crash" it is you might scratch the build plate was both refreshing ,and a little underwhelming.. LOL

2wdMod

RCTalk Talkaholic

Exactly!! My worst crash was one in the early 90's .. I was running a HUGE Mitutoyo BHN1325 CMM machine .. I forgot to remove a check stud from a hole and it crashed the probe, and the head.. about 20K in damages by the time the mitutoyo guys had to come rebuild it.. Yeah "coincidently" I was in the market for a new job a couple weeks later.. BTW , you start to view crashes a little different when its all on your dime.. Thats why I used crashing an end mill as an example as a minimal crash.. at $75 per tool , a bad afternoon of setting up a job crashing a couple tools and you have covered the cost of a printer, probably enough filament to run it for a couple weeks LOLShoot, I saw crashes costing tens of thousands of dollars. When a 3d printer crashes, it just goes click click click

Last edited:

WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,924

- Reaction score

- 21,117

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

That is the reason I left the best job I ever had. A guy crashed a Haas lathe, doing $12k damages, and the owner, who rarely spoke to us, pulled us all off to the side and said the next person that crashes a machine was getting fired. I left there a few weeks later, along with my buddy who crashed the lathe. He was actually moving back to Florida anyway. My boss tried to convince me I had nothing to worry about when I gave my notice, but it was too late. But in hindsight, leaving that shop was the dumbest move I ever made.Exactly!! My worst crash was one in the early 90's .. I was running a HUGE Mitutoyo BHN1325 CMM machine .. I forgot to remove a check stud from a hole and it crashed the probe, and the head.. about 20K in damages by the time the mitutoyo guys had to come rebuild it.. Yeah "coincidently" I was in the market for a new job a couple weeks later..

Last edited:

Not being a machinist I didnt understand any of what I was doing in the beginning. Kept getting failed print after failed print. If it hadnt been for WF teaching me Id have pitched that first one. Now I can make them print I just need to learn how to 3d model now.I have been a machinist for most of my life, I put getting a printer off until about 3 yrs ago .. I was intimidated by learning something new.. After I jumped in I actually was surprised as to how simple it really is.. Mainly I was intimidated by my own experience.. If I crash a mill with a .750" carbide end mill in it , thats a $75 crash minimum if it only takes out the tool.. Then theres the cost of the part that most likely was ruined in the crash.. So yeah to set up a machine that the worst things that happens when you "crash" it is you might scratch the build plate was both refreshing ,and a little underwhelming.. LOL

I also got an Ender 3 for Christmas, it's a good machine.Damn does this thing look sick got it yesterday assembled it and printed a gear came out like crap (it was not a good design it’s was for testing) going to print some Jerry cans today also might be getting a 1/10 crawler this week enless I pick something different

View attachment 157335

Which Ender 3 did you get?I also got an Ender 3 for Christmas, it's a good machine.

2wdMod

RCTalk Talkaholic

yeah that part will take some time and experimentation, but once you get a hold on the fact that if you can draw it you can make it real , your imagination really is your only limiting factor.Not being a machinist I didnt understand any of what I was doing in the beginning. Kept getting failed print after failed print. If it hadnt been for WF teaching me Id have pitched that first one. Now I can make them print I just need to learn how to 3d model now.

I think the v1.Which Ender 3 did you get?

- Messages

- 540

- Reaction score

- 889

- Location

- Western Washington

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

Not being a machinist I didnt understand any of what I was doing in the beginning. Kept getting failed print after failed print. If it hadnt been for WF teaching me Id have pitched that first one. Now I can make them print I just need to learn how to 3d model now.

What has helped me on the design side is re-working other designs to fit my needs.

2wdMod

RCTalk Talkaholic

YES!! that is a great way to start , by editing existing designs. Helps get your feet wet for sure.. STL editing took me a minute because its not really like editing a step file.. Its drag and drop compared to X,Y,Z coordinate based programs like standard solid works or even the BobCad/cam I use for my mill..What has helped me on the design side is re-working other designs to fit my needs.

- Messages

- 170

- Reaction score

- 165

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

I just made my first 3d print (benchy). It turned out very good, the only problems I noticed were, a little stringing and for some reason there was a vertical line (1.5mm wide) that the filament wasn't done right. What would cause this? I would take a picture, but I used black pla, so the picture wouldn't be high res enough for you to see what I am talking about.