Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

More options

Who Replied?WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,924

- Reaction score

- 21,117

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

Screwing parallel to the layers is always a bit risky. Especially on thinner parts.

The resin trick is really awesome. I have been using it for awhile now. I wish I had found it sooner. Oh the headaches it would have saved me trying to print tiny parts, yet keep them strong.

The resin trick is really awesome. I have been using it for awhile now. I wish I had found it sooner. Oh the headaches it would have saved me trying to print tiny parts, yet keep them strong.

- Messages

- 1,325

- Reaction score

- 1,745

- RC Driving Style

- Racing

- Thread starter

- #303

A professional machine with a heated enclosure would have better layer adhesion even with an FDM process.

Agreed, but I don't think any FDM process will be sufficient for this particular part.

WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,924

- Reaction score

- 21,117

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

That is true. A heated enclosure is the way to go on any 3d printing. I'd love to get one for my main printer, but with a 500mm x 500mm x 500mm build volume, I need a heated closet lol.A professional machine with a heated enclosure would have better layer adhesion even with an FDM process.

- Messages

- 1,325

- Reaction score

- 1,745

- RC Driving Style

- Racing

- Thread starter

- #305

Screwing parallel to the layers is always a bit risky. Especially on thinner parts.

The resin trick is really awesome. I have been using it for awhile now. I wish I had found it sooner. Oh the headaches it would have saved me trying to print tiny parts, yet keep them strong.

I used this stuff - https://www.elegoo.com/products/elegoo-plant-based-rapid-resin?variant=39469352452144 but in clear, after doing some research. Stuff is literally made from soybeans!

I was printing fishing lures, and standard resins were just too brittle, and some people recommended this because it's far more pliable. Been using it for a few years now, and it's non-irritant for the most part, doesn't stink up the place either. And yes, the detail levels are vastly better, that was really important for my lures.

WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,924

- Reaction score

- 21,117

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

I haven't tried Elegoo, but I have been considering one of their resin printers. I just hate the mess of resin printing.I used this stuff - https://www.elegoo.com/products/elegoo-plant-based-rapid-resin?variant=39469352452144 but in clear, after doing some research. Stuff is literally made from soybeans!

I was printing fishing lures, and standard resins were just too brittle, and some people recommended this because it's far more pliable. Been using it for a few years now, and it's non-irritant for the most part, doesn't stink up the place either. And yes, the detail levels are vastly better, that was really important for my lures.

The resin I use is standard resin, that stinks, and you have to wear gloves. But that's not really a big deal because I only ever use a few drops of it on my tiny SCX24 parts I print.

- Messages

- 1,325

- Reaction score

- 1,745

- RC Driving Style

- Racing

- Thread starter

- #307

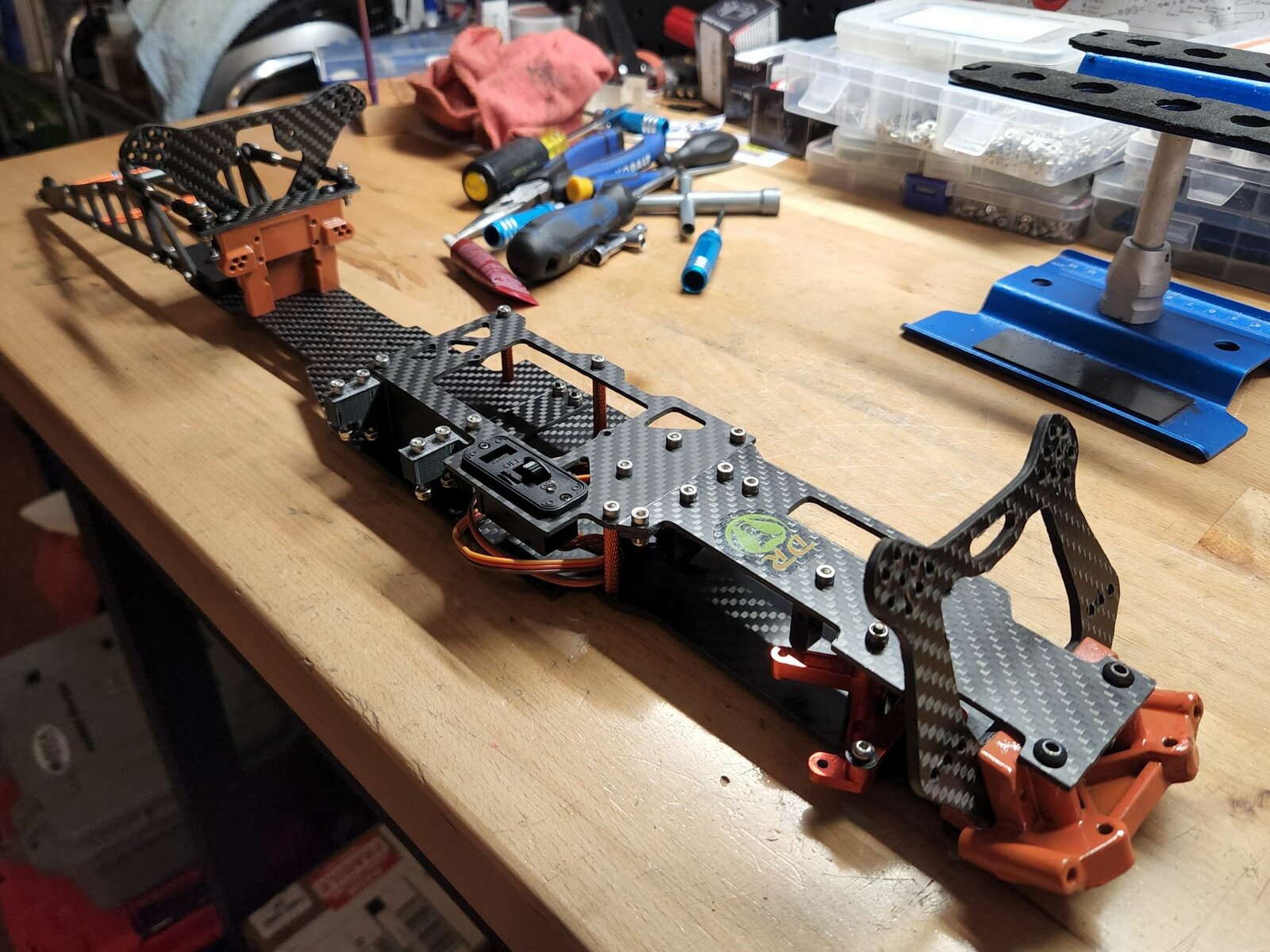

This one is done, and it will be built and tested by my teammate next week.

I think though I'm going to just use stock front bulkheads from here on out though - they are only 6 dollars, lol. Still will probably paint them and color match them with the rear ones. It also occurred to me that I don't need the rear one to be hollowed out in the middle (that's for the Slash/Rustler trans to slip into) - so I can make these stronger yet. I've since coated the paint with Flexseal clear to protect from nitro fuel.

I think though I'm going to just use stock front bulkheads from here on out though - they are only 6 dollars, lol. Still will probably paint them and color match them with the rear ones. It also occurred to me that I don't need the rear one to be hollowed out in the middle (that's for the Slash/Rustler trans to slip into) - so I can make these stronger yet. I've since coated the paint with Flexseal clear to protect from nitro fuel.

WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,924

- Reaction score

- 21,117

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

Holy cow man. Wow. What's the name of your RC company? Because you're at that level.

- Messages

- 1,325

- Reaction score

- 1,745

- RC Driving Style

- Racing

- Thread starter

- #309

Holy cow man. Wow. What's the name of your RC company? Because you're at that level.

Wow thanks man!

Diamond Racing will be the name they are built under and the name I've used for my "garage" for some years. I've got a website, but haven't finished and uploaded it just yet.

The next ones built will be this week, and the level of hardware is a step up, using anodized countersunk washers, and non-twill CF. Two of those are sold already to teammates. The last one I'll stick on eBay after I get some feedback from those guys.

- Messages

- 9,250

- Reaction score

- 16,541

- Location

- Central California

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

- Flying

I was just going to ask if the decal on the Carbon Fiber was yours, if not it should be, but you answered that! Good luck with production and sales, it's a really sweet setup.

That drag chassis looks slick AF

- Messages

- 1,325

- Reaction score

- 1,745

- RC Driving Style

- Racing

- Thread starter

- #312

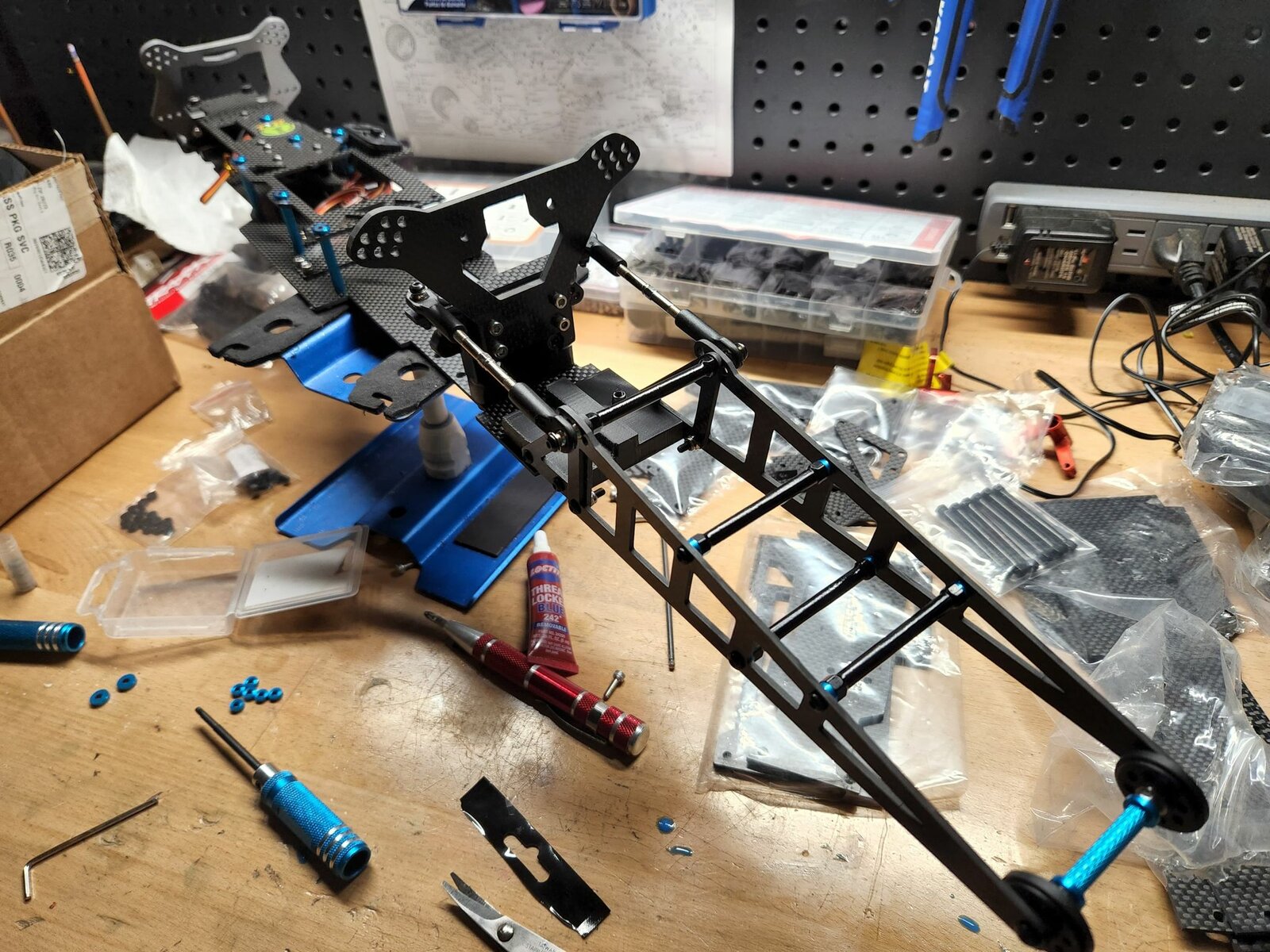

The second one is in progress and is more indicative of what the real product is. Still have to print out the throttle servo mount and add the steering block, and screw down the on/off switch (requires drilling tiny holes).

- Messages

- 9,250

- Reaction score

- 16,541

- Location

- Central California

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

- Flying

What is taking so long? Get crackin' man!

Jaydiaz1993

RCTalk Qualifier

- Messages

- 167

- Reaction score

- 81

Very impressive and informative, I am changing my Nitro rustler to a 2 speed gearing and this post is hugely appreciatedThis is getting very close. Engine mount is finished, and I scored an alloy spur guard/brace. Just a couple of items to finish/cleanup, and need a warmer day to do a little testing. Yesterday woulda been perfect, but ah well. It was 70. Today it's 40, lol.

View attachment 136850

The brace works just about perfect, and I had some other piece (the little red thing at the end) from something I don't even know what, that allowed me to mount it to the chassis plate. There is even already a hole there (though it needs a slight tweak to line up perfectly).

View attachment 136851

I also scored some orange arm hinge mounts to replace the blue ones that didn't match the rest of the chassis. Those I had to grind down a bit because the transmission wasn't fitting with them. Note, steel spur gear too. No slipper either.

View attachment 136852

I will test pretty thoroughly with the OS .21 tm first. I'm really curious as to how much time will come off my ET's. My best time with the previous single speed Slash trans was 2.7s, which isn't all that fast (2 years ago that was considered fast though). Now guys are all 2-2.5s with SC chassis cars, and some are sub 2s. I'd be pretty happy with something in the low 2s range with this mill.

Then I will beef up the transmission, replacing all of the internals with steel gears, and better bearings. Because, you know, the next step is slapping a big block in this thing. The BB mount has the same bolt pattern in the base as the SB mount, so my existing CF mount plate will work just fine.

View attachment 136853

I will start with the KE25 and see how that performs. They aren't really the best, and I can't find specs on it but I don't think it's got a lot of top end. I just want to see how it launches, etc, and if things hold up with that somewhat tame BB mill. Then I will put in the Final Destination engine, the O.S .28 p8 which does have decent top end at 36k, and I'll also change the 54t spur to a 53t.

The SH is a 4+ hp monster, I have one in my Dragonoid, and it's a drivetrain wrecker in that rig, but this is going to be a pretty bulletproof drivetrain before I put that thing in. I am still searching daily for an alloy gear case, but no luck yet. Probably will have to wind up buying some Jato roller to get one, lol. Anyway, with that much power, the power to weight ratio for this car will be insane - comparable, or exceeding that of BoLink/RJ Speed pan drag cars. Those nitro cars run times as low as 1.6s, I've seen the slips. Currently the fastest SC chassis car time recorded is 1.78s, set very recently by Frank Uldrick (I think he works for a chassis builder). I'm not sure what motor combo he was running, might have been 4s or 6s, not sure, could have even been 3s to keep it NPRC legal, but that seems a little unlikely. Either way, I am gunning to break that record. With nitro. The power/weight numbers will be there, but can I get it to the pavement? That's going to be the real test. I had some traction issues with the OS .21 tm when I initially built this thing and had the short gears in with no top end speed, and now with the 2 speed it'll be even shorter and torquier on launch. The car also weighed 6.6 lbs then (with body), but is only a little over 5 now. I might have to re-add some weight, and find the magic combo.

Now just have to wait for the weather to be warm enough to run.

- Messages

- 1,325

- Reaction score

- 1,745

- RC Driving Style

- Racing

- Thread starter

- #315

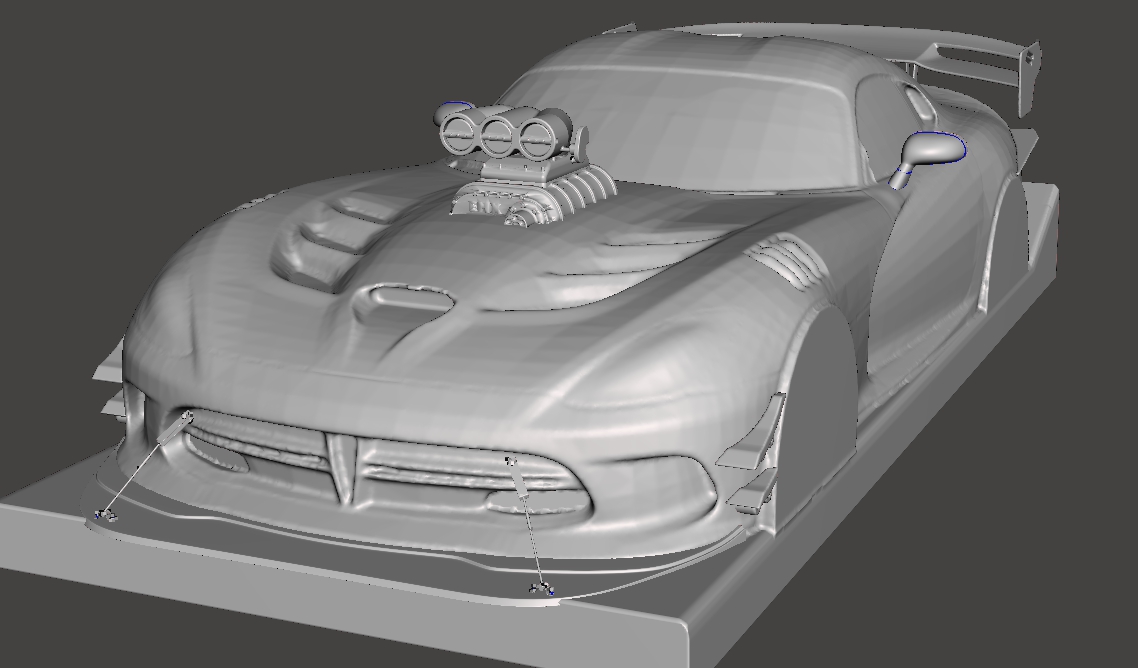

Been mulling something over in my mind for a few months, but just didn't think I could pull it off because it's a difficult project, and my vacuum former isn't large enough to accommodate 1/8th scale car bodies - but - I really, really, really want a 4th gen Dodge Viper ACR body. I saw a 1/4 scale one out there, and how it was done in two pieces(the Viper bodies do lend themselves to being "dividable" like that due to their design), and it got me thinking...

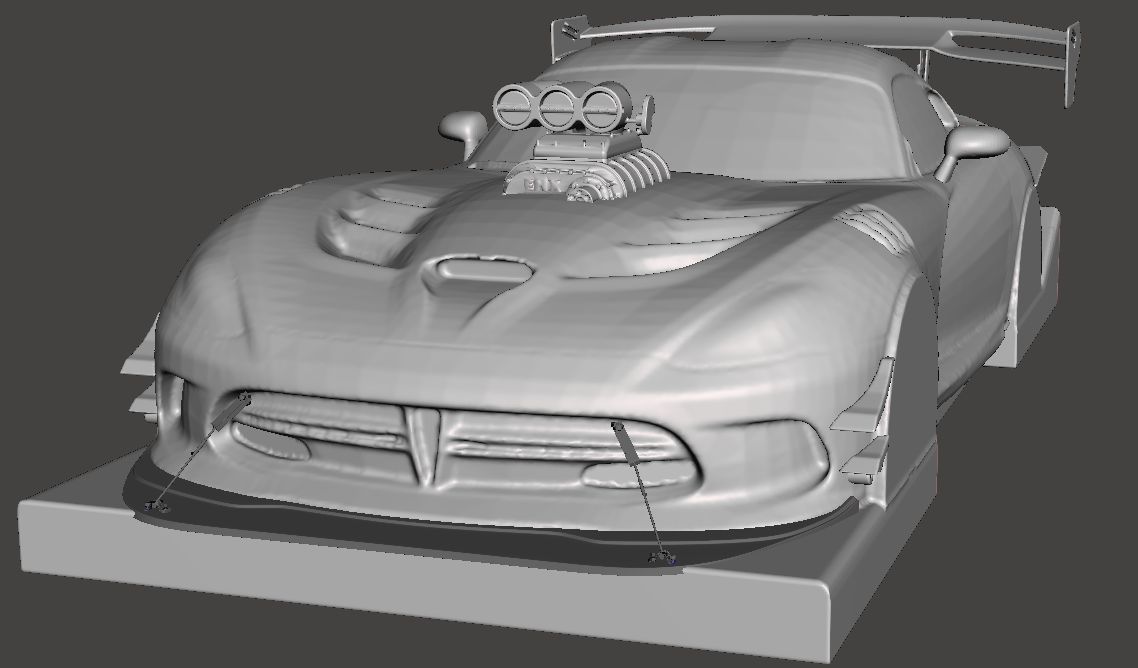

Was there a good, free Viper ACR model out there? Yup...several. That gave me a starting point. After trying a few to attempt to create usable solids, I finally got one working, worked up the dimensions needed and scaled it accordingly. Some of it would be 3d printed - cannards, blower/scoop, mirrors, some pieces cut from CF, etc. Here's a pic with the body and the parts all attached -

The fender "grills" are kinda messy, but I'm probably cutting the lexan away and putting 3d printed ones in, so not worried 'about that. I'm printing headlight buckets in clear resin, and they will have green center bulbs, and a white bulb that will light up the perimeter lines like the real thing. I will do tail lights too, that's something missing in all my cars actually.

I cut the molds, it's one for the front, one for the rear. Each of those was sliced into four pieces, and they *barely* fit on the Ender-3. Each of those is going to take about 12-15 hours to print (!).

I'm going to fill the molds with Foam-it casting foam. I'll sand that down to get rid of the roughness of the 3d print, then coat it with epoxy and sand some more. I've never worked with this stuff before, but I wanted something other than water putty that is a little more flexible and that I can demold without breaking anything off, give there's a decent amount of cross-undercuts that will probably hang up a bit - might even have to break the mold to get it out, but I don't care about that. This stuff is good to 200c, so it should hold up well when vacuum forming.

I really hope the body sits down on the chassis well, I measured everything very carefully, many times, and the profile is very similar to my existing Vette body, so I think it'll be good, maybe even a little better in the rear area. I'm wondering if the rear wheel wells are going to be full enough when compressed down, but my contingency plan is that I'll print out some flares and mount them to the form if I need to and re-vacuum the rear section. The front should have plenty of room, even better than the Vette due to the way it's shaped.

The rear wing will be a little different than how it looks here. It's going to have two adjustment points, one at the car body, another at the wing - so that it can be laid down lower, and the angle of the wing changed too. The struts will be cut from CF, the outer parts from CF, and the middle section formed from lexan. This is one of the reasons I really wanted to do this, to give an actual useful tuning tool on the body itself. The front splitter will be done the same as I did the Vette, out of CF, and using the metal struts and joints.

The two halves of the body will be screwed together. There will be a few across the cowl, one going into the mirrors, another into the exhaust, and probably two more along the front wheel well, but those that are exposed will be very small 2m black bolts.

In the end it'll be painted up similar to the Vette bodies. I mocked up what the general goal of this thing is -

Was there a good, free Viper ACR model out there? Yup...several. That gave me a starting point. After trying a few to attempt to create usable solids, I finally got one working, worked up the dimensions needed and scaled it accordingly. Some of it would be 3d printed - cannards, blower/scoop, mirrors, some pieces cut from CF, etc. Here's a pic with the body and the parts all attached -

The fender "grills" are kinda messy, but I'm probably cutting the lexan away and putting 3d printed ones in, so not worried 'about that. I'm printing headlight buckets in clear resin, and they will have green center bulbs, and a white bulb that will light up the perimeter lines like the real thing. I will do tail lights too, that's something missing in all my cars actually.

I cut the molds, it's one for the front, one for the rear. Each of those was sliced into four pieces, and they *barely* fit on the Ender-3. Each of those is going to take about 12-15 hours to print (!).

I'm going to fill the molds with Foam-it casting foam. I'll sand that down to get rid of the roughness of the 3d print, then coat it with epoxy and sand some more. I've never worked with this stuff before, but I wanted something other than water putty that is a little more flexible and that I can demold without breaking anything off, give there's a decent amount of cross-undercuts that will probably hang up a bit - might even have to break the mold to get it out, but I don't care about that. This stuff is good to 200c, so it should hold up well when vacuum forming.

I really hope the body sits down on the chassis well, I measured everything very carefully, many times, and the profile is very similar to my existing Vette body, so I think it'll be good, maybe even a little better in the rear area. I'm wondering if the rear wheel wells are going to be full enough when compressed down, but my contingency plan is that I'll print out some flares and mount them to the form if I need to and re-vacuum the rear section. The front should have plenty of room, even better than the Vette due to the way it's shaped.

The rear wing will be a little different than how it looks here. It's going to have two adjustment points, one at the car body, another at the wing - so that it can be laid down lower, and the angle of the wing changed too. The struts will be cut from CF, the outer parts from CF, and the middle section formed from lexan. This is one of the reasons I really wanted to do this, to give an actual useful tuning tool on the body itself. The front splitter will be done the same as I did the Vette, out of CF, and using the metal struts and joints.

The two halves of the body will be screwed together. There will be a few across the cowl, one going into the mirrors, another into the exhaust, and probably two more along the front wheel well, but those that are exposed will be very small 2m black bolts.

In the end it'll be painted up similar to the Vette bodies. I mocked up what the general goal of this thing is -

WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,924

- Reaction score

- 21,117

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

This is going to be sick. I definitely want a body if you decide to sell any.

I'm as hard as a diamond in an ice storm rn.

- Messages

- 1,325

- Reaction score

- 1,745

- RC Driving Style

- Racing

- Thread starter

- #318

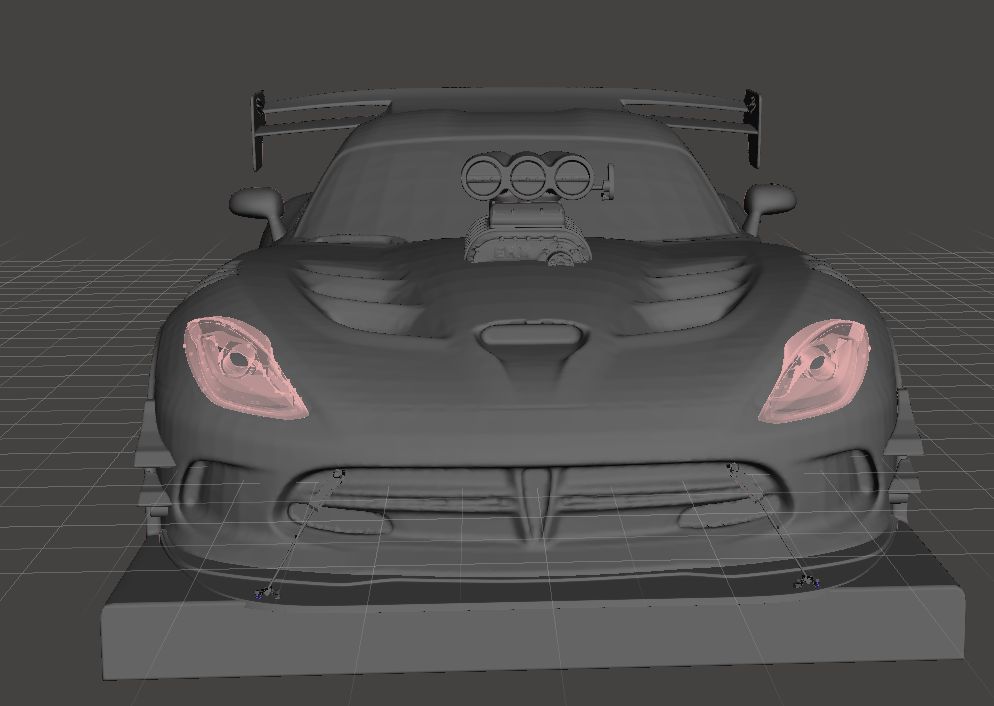

Got the headlight buckets into printable solid pieces - these will be done in clear resin, with a green LED for the main bulb, and a white one that will light up the inside of the resin that will be painted black except for the perimeter accents.

Fixed a snafu - I somehow cut the lower rocker panels off (man I sense a theme with that mistake!). I've already printed out two of the front mold pieces, so I had to make a "fix" that will glue into those to add the missing rocker panel. It was easy, but took my mind some time to figure out what to do, lol.

This is what the "buck" should be shaped like (Minus all the decorations of mirrors, engine, splitter, cannards, wing). I can see why I made the mistake, I was focused on getting the front sliced off right so that it wasn't undercut, and it took the rockers with it. Might be fun getting the lexan off the buck with those undercut rockers, but shouldn't be that bad with .040, I've definitely wrestled more difficult things off before.

Also fixed the spoiler scale, and now I need to design the CF struts and 3D printed mounts. The wing stabilizers will be 1mm CF, as will the splitter, and both of those I'll use my router to cut.

Fixed a snafu - I somehow cut the lower rocker panels off (man I sense a theme with that mistake!). I've already printed out two of the front mold pieces, so I had to make a "fix" that will glue into those to add the missing rocker panel. It was easy, but took my mind some time to figure out what to do, lol.

This is what the "buck" should be shaped like (Minus all the decorations of mirrors, engine, splitter, cannards, wing). I can see why I made the mistake, I was focused on getting the front sliced off right so that it wasn't undercut, and it took the rockers with it. Might be fun getting the lexan off the buck with those undercut rockers, but shouldn't be that bad with .040, I've definitely wrestled more difficult things off before.

Also fixed the spoiler scale, and now I need to design the CF struts and 3D printed mounts. The wing stabilizers will be 1mm CF, as will the splitter, and both of those I'll use my router to cut.

Let me know if this goes in to production. I want one

- Messages

- 1,325

- Reaction score

- 1,745

- RC Driving Style

- Racing

- Thread starter

- #320

Let me know if this goes in to production. I want one

It's not likely - but I'll let you know if I do.

Re-checked some measurements on the tires/wheels for interference, and realized quickly that it's a good thing I did before starting the rear half mold prints! Definitely needed to add some fender flares on the back. Front tires are good as is, and clear the headlight buckets when turned.

Also finished up the design of the spoiler mounts, and now it'll tilt down and work like a promod Viper.

This image shows how the body halves mate up and bolt. Profile is overall very similar to the Vette, but a little shorter in the rear. I'm definitely drilling small air holes in the buck in the crevice areas to pull the lexan tight. Might have to poke holes with a 1mm wire rod for some taller areas like the window scoops.

All parts are finished the design phase, it's just a matter of waiting on all this crap to print. I wish I had a few Ender3's instead of the one. Headlight buckets I started printing last night as well on the Photon. LED's are arriving by Friday. Decent chance I get the front half assembled by Saturday, but the rear probably won't get done until Tuesday or so.