This build is looking really nice man!

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

More options

Who Replied?WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,922

- Reaction score

- 21,116

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

My very first car was a 65 Mustang. It was missing the grille bars in the front grille that extend off each side of the horse corral in the center, and I was too poor to buy new ones, even if I could find them.Nothing better than sitting in the shop on a Sunday morning. Just tinkering with my drag car.

I was thinking about how the tires expand and rub the body. I have belted tires but I don’t want the ugly black half moons so I covered the inside with aluminum. It’s tape for duct work and it’s .02mm thick. Has a nice glue on like a sticker.

The cool thing is it’s so thin you can rub out wrinkles with you thumbnail. I am going to bet you could use this stuff to cover panels on the outside. And polish it or make it look like metal.

It wraps around corners and sticks pretty well. The writing comes off with alcohol.

I’m going to mess with this stuff today.

My dad had a badass woodshop and lots of high end hardwood. So I traced the shape of the bars I needed onto pieces of wood and made them on the bandsaw. I then took some similar aluminum tape and wrapped and polished them. From even close up, people could never tell they were fake.

- Messages

- 1,486

- Reaction score

- 2,612

- Location

- Iowa

- RC Driving Style

- Racing

- Crawling

- Scale Builder

- Flying

- Thread starter

- #103

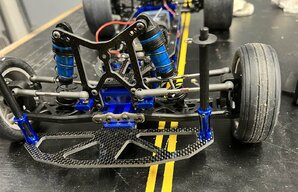

Been playing with the corner weight scale. I don’t have the proper parts but I just want to see how easy it is to adjust the corner weights. My thinking is to set everything to even 50- 50 side to side and then 30-70 front to rear and half power, middle gear set.

As the power comes up it will want to go right I believe so I can adjust from this neutral point.

It’s just a mater of moving and changing shims. And the sway bar end links. Even 1mm from side to side makes a difference on the scale.

Only going two digits since I can’t adjust the springs with threaded collar.

As the power comes up it will want to go right I believe so I can adjust from this neutral point.

It’s just a mater of moving and changing shims. And the sway bar end links. Even 1mm from side to side makes a difference on the scale.

Only going two digits since I can’t adjust the springs with threaded collar.

Attachments

- Messages

- 1,486

- Reaction score

- 2,612

- Location

- Iowa

- RC Driving Style

- Racing

- Crawling

- Scale Builder

- Flying

- Thread starter

- #104

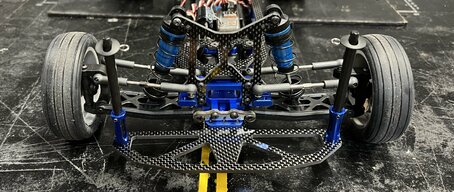

I made a tow gauge to set the front end. The rear is pre set but the front is adjustable . Since I changed the front caster with the different bulkhead I reset the camber and the toe. After that I wipe off the tires and roll it across the floor. With no motor it’s pretty smooth. Photos show before and after .

Attachments

Last edited:

- Messages

- 1,486

- Reaction score

- 2,612

- Location

- Iowa

- RC Driving Style

- Racing

- Crawling

- Scale Builder

- Flying

- Thread starter

- #105

I put a red LED on the wheelie bar. Just for visibility and so I know if I have the radio turned on.

It’s just a rod end with the 5mm LED held in place with an O ring and some glue.

It’s just a rod end with the 5mm LED held in place with an O ring and some glue.

Attachments

Good idea with the power on rain light. Be good for night events and days with limited visibility 132ft down range.I put a red LED on the wheelie bar. Just for visibility and so I know if I have the radio turned on.

It’s just a rod end with the 5mm LED held in place with an O ring and some glue.

Both my bracket truck and rail scored a fair number of round wins against cars in the other lane failing to switch on. Left them behind sitting dead at stage. My drag racers ran a fan on the ESC. Not for cooling, but the vibration of the fan through the chassis re-assured me car was switched on. In the excitement and hustle of pre-stage, it is easy to forget.

Personally, I've always been a proponent of staging by radio rather than hand staging. Inevitably, that puts me in the minority. Makes racing more realistic and evens the odds a bit at launch. Also makes staging part of the race more so than an exercise in exact positioning of the car. Staging by hand is more about aiming the car. Radio staging ups the skill quotient a notch. And, by its very nature, eliminates overlooking a switch on.

Exciting build, you have there. Both you and Breydon posting up some good stuff here. Cheers and round wins guys. 'AC'

- Messages

- 1,486

- Reaction score

- 2,612

- Location

- Iowa

- RC Driving Style

- Racing

- Crawling

- Scale Builder

- Flying

- Thread starter

- #107

I also got my body mounts. These make a complete circle of metal around the transmission and motor. The whole cage is under tension and the shims between the shock towers is deleted.

The only thing left is the original plastic transmission. I’m working on that. And I want to build a slipper clutch.

But for now the chassis is done. Now to add power.

The only thing left is the original plastic transmission. I’m working on that. And I want to build a slipper clutch.

But for now the chassis is done. Now to add power.

Attachments

Another great looking build man. I'm jelly!

- Messages

- 1,486

- Reaction score

- 2,612

- Location

- Iowa

- RC Driving Style

- Racing

- Crawling

- Scale Builder

- Flying

- Thread starter

- #109

Well I’m burning rubber and doing wheelies!! Other than that last night was a total disaster.

Ok I have some solvable issues.

I bought a carbon fiber plate to mount the ESC above the battery. That allows me to move the battery back and forth.

First off I don’t like moving the CG up. And turning the battery around makes the wires from the ESC to short. And puts the motor leads pushed toward the sway bar. Could make an extension or use a battery with a lead and plug, but the weight is already perfect so that was a waste of time and money. About 15 bucks. I’ll use it someplace.

Second the steering block. Bump steer comes from having the tie rods at angles because of the position of the steering rack. When I went to the zero caster set up I figured I needed the zero caster rack mount. The bump steer was minimal but I ordered the other mount. Now when you push on the front end the wheels practitioners clap together. And I can’t mount the servo horn. Need totally different steering arms or just go back to the original rack mount. Fail number two.

Now let’s talk about solder. I bought super cool little heat sink bullet connectors. The monster X uses 8 AWG on the battery side with 5mm bullets. The ones I got are to small.

And the motor wiring is to short. But that was not my real problem. I have a 30 watt soldering iron. I would like to use lead free solder because of the higher melt point than lead. And the wiring are already tinned with lead free. My cheep 30 watt soldering iron won’t melt the lead free solder and trying lead solder made a crumbly alloy and That made a mess of things. I got them soldered but it is totally unacceptable cold solder.

I’m going to need a 70-100 watt soldering iron for get enough heat quickly enough to properly solder heavy 10 gauge wires.

But the battery and ESC fit and was programmed with castle link. Set up the motor, and I was able to spin the shine off the tires and do a tiny little wheelie. So it’s all good.

Ok I have some solvable issues.

I bought a carbon fiber plate to mount the ESC above the battery. That allows me to move the battery back and forth.

First off I don’t like moving the CG up. And turning the battery around makes the wires from the ESC to short. And puts the motor leads pushed toward the sway bar. Could make an extension or use a battery with a lead and plug, but the weight is already perfect so that was a waste of time and money. About 15 bucks. I’ll use it someplace.

Second the steering block. Bump steer comes from having the tie rods at angles because of the position of the steering rack. When I went to the zero caster set up I figured I needed the zero caster rack mount. The bump steer was minimal but I ordered the other mount. Now when you push on the front end the wheels practitioners clap together. And I can’t mount the servo horn. Need totally different steering arms or just go back to the original rack mount. Fail number two.

Now let’s talk about solder. I bought super cool little heat sink bullet connectors. The monster X uses 8 AWG on the battery side with 5mm bullets. The ones I got are to small.

And the motor wiring is to short. But that was not my real problem. I have a 30 watt soldering iron. I would like to use lead free solder because of the higher melt point than lead. And the wiring are already tinned with lead free. My cheep 30 watt soldering iron won’t melt the lead free solder and trying lead solder made a crumbly alloy and That made a mess of things. I got them soldered but it is totally unacceptable cold solder.

I’m going to need a 70-100 watt soldering iron for get enough heat quickly enough to properly solder heavy 10 gauge wires.

But the battery and ESC fit and was programmed with castle link. Set up the motor, and I was able to spin the shine off the tires and do a tiny little wheelie. So it’s all good.

Attachments

- Messages

- 9,249

- Reaction score

- 16,540

- Location

- Central California

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

- Flying

Sounds like fun, NOT! Setbacks are annoying, but fixable.

Personally I would not suggest using lead free solder. Not that you can't make it work but its harder to work with, its more expensive, It hardens with a dull look so it makes it harder to tell how much oxidization is in your solder joint, and the higher temps needed to melt lead-free solder comes with significant component stress; therefore, low dielectric components are more vulnerable to failures. Lead-Free also has lower "wettability". Low wettability makes the solder joint function ineffectively in meeting the demands of self-regulation ability, tensile power, and shear capacity. Consequently, low wettability causes a high rejection rate of solder joints, especially when you fail to conduct adjustments to cater to this shortcoming.I have a 30 watt soldering iron. I would like to use lead free solder because of the higher melt point than lead. And the wiring are already tinned with lead free. My cheep 30 watt soldering iron won’t melt the lead free solder and trying lead solder made a crumbly alloy and That made a mess of things. I got them soldered but it is totally unacceptable cold solder.

I’m going to need a 70-100 watt soldering iron for get enough heat quickly enough to properly solder heavy 10 gauge wires.

Theres a whole lot of other drawbacks to using lead free solder but they mainly have to do with soldering on PCBs which isnt something most of us have to worry about but the other things I listed are things you should take in to account.

Either way though Id move up to a 60W soldering station

Last edited:

- Messages

- 1,486

- Reaction score

- 2,612

- Location

- Iowa

- RC Driving Style

- Racing

- Crawling

- Scale Builder

- Flying

- Thread starter

- #112

I have plenty of both but yes I don it like lead free solder.

I tried a 100 watt pistol grip soldering gun. It did nothing but over heat the wires. I have a butane soldering pen that worked great. Should have got that out last night.

What a difference.

These little heat sinks also form a mechanical bond bolting the soldered wire to the post. On the right is last nights mess.

I tried a 100 watt pistol grip soldering gun. It did nothing but over heat the wires. I have a butane soldering pen that worked great. Should have got that out last night.

What a difference.

These little heat sinks also form a mechanical bond bolting the soldered wire to the post. On the right is last nights mess.

Attachments

Last edited:

Those heat sink connector look pretty cool

- Messages

- 1,486

- Reaction score

- 2,612

- Location

- Iowa

- RC Driving Style

- Racing

- Crawling

- Scale Builder

- Flying

- Thread starter

- #114

I have to order some 4mm bullet connectors that have a nail shape head.

And I have more 10AWG wiring coming with 6.5mm ends pre soldered so all I have to do is the motor.

I also found the proper linkage for the steering.

I think I’m almost to the point that I might as well replace the control arms and put together a stock DR10 from all the parts.

And I have more 10AWG wiring coming with 6.5mm ends pre soldered so all I have to do is the motor.

I also found the proper linkage for the steering.

I think I’m almost to the point that I might as well replace the control arms and put together a stock DR10 from all the parts.

I've been wondering about these types of conversion chassis and whether or not it would be better to use one or just order a dedicated kit.I have to order some 4mm bullet connectors that have a nail shape head.

And I have more 10AWG wiring coming with 6.5mm ends pre soldered so all I have to do is the motor.

I also found the proper linkage for the steering.

I think I’m almost to the point that I might as well replace the control arms and put together a stock DR10 from all the parts.

- Messages

- 1,486

- Reaction score

- 2,612

- Location

- Iowa

- RC Driving Style

- Racing

- Crawling

- Scale Builder

- Flying

- Thread starter

- #116

I think it depends on the level of interest first. And how much experience you have and extra parts you have. I can build a crawler from aftermarket parts with ease. Building a vehicle that you never built before or even drove before is going to have issues with the learning curve.

I think the no prep world is going to get more popular and that will lead to more money for R and D. So if you just starting out. Cheapest is an RTR and from there speed is money.

I think the no prep world is going to get more popular and that will lead to more money for R and D. So if you just starting out. Cheapest is an RTR and from there speed is money.

- Messages

- 1,486

- Reaction score

- 2,612

- Location

- Iowa

- RC Driving Style

- Racing

- Crawling

- Scale Builder

- Flying

- Thread starter

- #117

Thing I got most of the issues work out and next year is looking good.

Got the ESC and motor and some wires and the like. But it’s all up and weight 4.75 pounds.

Added one shim to the right front and the corners went perfect. Hope everyone has a great Christmas.

Got the ESC and motor and some wires and the like. But it’s all up and weight 4.75 pounds.

Added one shim to the right front and the corners went perfect. Hope everyone has a great Christmas.

Attachments

- Messages

- 9,249

- Reaction score

- 16,540

- Location

- Central California

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

- Flying

@Iowa crawler Hope you have a great Christmas as well.

WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,922

- Reaction score

- 21,116

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

Looking good man. I spent the last 2 days prepping and masking the body, and I still have a lot of masking to do. I decided to do the trim around the windows in chrome, so just masking that all off with my old eyes has been a challenge. Still have to mask the bumpers in, so hopefully tomorrow I can get the chrome sprayed at least. I may try using liquid mask for the bumpers.

- Messages

- 1,486

- Reaction score

- 2,612

- Location

- Iowa

- RC Driving Style

- Racing

- Crawling

- Scale Builder

- Flying

- Thread starter

- #120

I have been playing with the front steering linkage. It still has just a little bit of bump steer. I have the links level and the chassis is just nose down a fraction. I don’t even know if that is good.

I think the angle of the steering blocks from the DR10 kit are doing something strange with the zero caster bulkhead. Seems odd and probably steers just fine. But when you move the chassis up and down. The wheels move in and out just a little.

I think the angle of the steering blocks from the DR10 kit are doing something strange with the zero caster bulkhead. Seems odd and probably steers just fine. But when you move the chassis up and down. The wheels move in and out just a little.