Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

More options

Who Replied?- Messages

- 5,976

- Reaction score

- 9,896

- Location

- Baltimore

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

- Thread starter

- #22

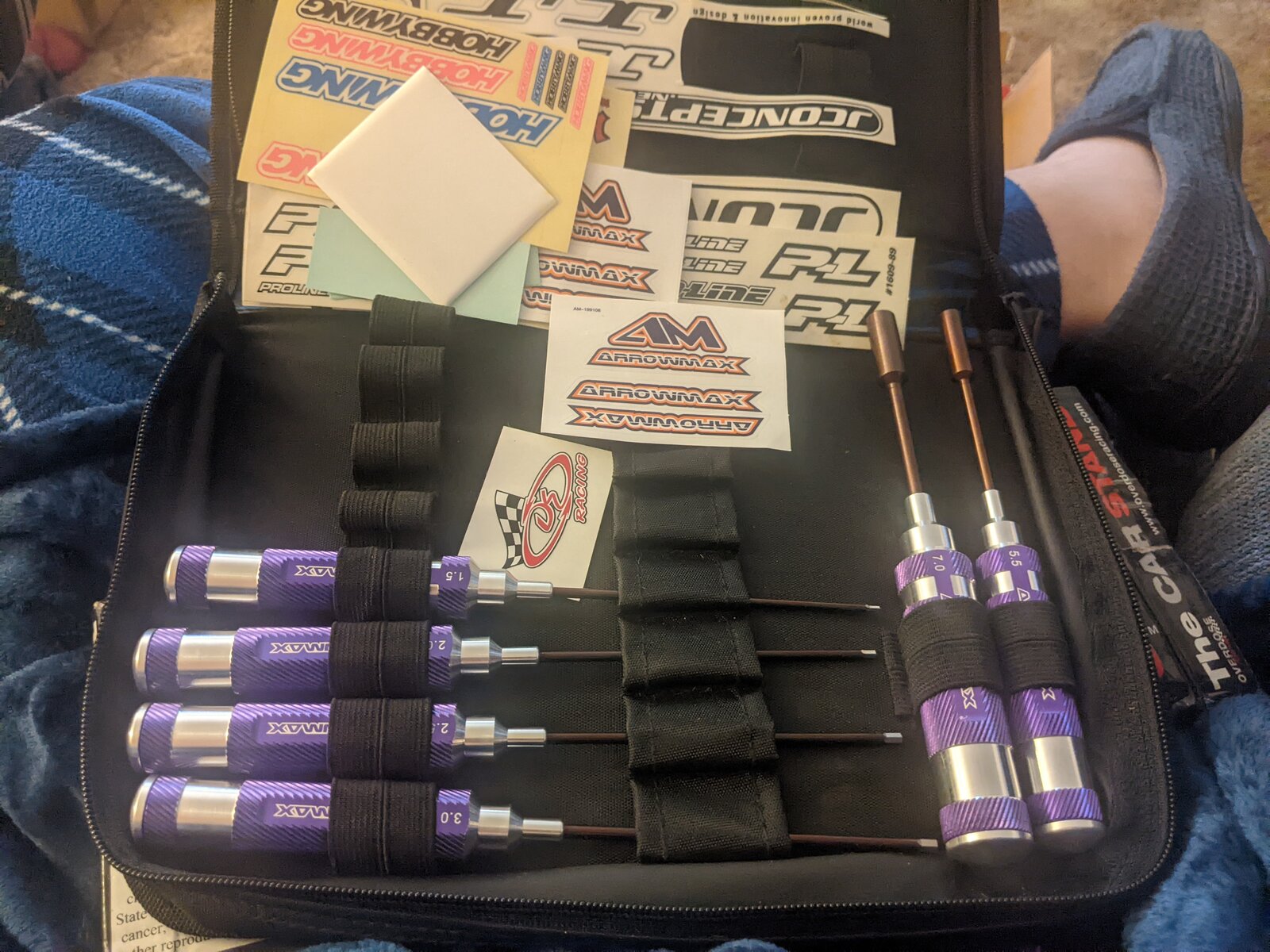

My uncle actually stipped out my 1.5 driver so he is ordering a replacement tip for me. Good tools so far. I like that they are longer so I can do hard to reach spots.

www.am-arrowmax.com

www.am-arrowmax.com

Here's my order of preference:

1) At the first hint of screw head starting to strip I will heat the screw with a micro-torch to melt thread lock then back out the screw:

https://www.amazon.com/Refillable-Butane-Soldering-Jewelry-Pinpoint/dp/B0733SWJQL/

2) If that doesn't work then I try to use an Extractor:

https://www.amazon.com/Nuovoware-Extractor-Stripped-All-purpose-Extension/dp/B08XXP1SD9

3) If that doesn't work then I use a Dremel/Rotary to cut a slot to use a flat head screwdriver to extract the bit:

https://www.amazon.com/gp/product/B07FSBY9GV

4) If that doesn't work then I use a grinding bur bit with the rotary to completely grind away the head of the screw, remove the part and use pliers to extract the threads --- this is my absolute last resort as this risks damaging other parts

I make it a point to regularly replace any screws and hex bits at the first sign of any rounding.

I have been able to refresh my hex bits by cutting off rounded tips with my rotary tool and can do this several times on a bit before it needs to be discarded.

As a preventative, I replace button head screws with socket heads to extend the life of screws, especially on the motor mounts!

1) At the first hint of screw head starting to strip I will heat the screw with a micro-torch to melt thread lock then back out the screw:

https://www.amazon.com/Refillable-Butane-Soldering-Jewelry-Pinpoint/dp/B0733SWJQL/

2) If that doesn't work then I try to use an Extractor:

https://www.amazon.com/Nuovoware-Extractor-Stripped-All-purpose-Extension/dp/B08XXP1SD9

3) If that doesn't work then I use a Dremel/Rotary to cut a slot to use a flat head screwdriver to extract the bit:

https://www.amazon.com/gp/product/B07FSBY9GV

4) If that doesn't work then I use a grinding bur bit with the rotary to completely grind away the head of the screw, remove the part and use pliers to extract the threads --- this is my absolute last resort as this risks damaging other parts

I make it a point to regularly replace any screws and hex bits at the first sign of any rounding.

I have been able to refresh my hex bits by cutting off rounded tips with my rotary tool and can do this several times on a bit before it needs to be discarded.

As a preventative, I replace button head screws with socket heads to extend the life of screws, especially on the motor mounts!

WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,949

- Reaction score

- 21,185

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

I have never had to go to those extremes on an RC car. If a quality allen bit starts to strip the screw, I'll put a drop of PB Blaster on it overnight and use whatever torx bit I can press into it to remove the screw. But I rarely even have to go that far. Tip - inward pressure is just as important as turning pressure. You gotta put a lot of downforce to keep the bit engaged. And sometimes a slight right-hand turn can break a screw loose.

There are some blends of plastic with race grade cars that can grab onto the M4 flat head screws with far greater force than you might expect. The root of the problem is when the chassis wears, the head of the screw wears with it and you loose depth for the bit to get into the head and to make matters worse is caked up mud/dirt filled into the screw head. It's a must for every racer to use a pick to remove the dirt but hard to get it all out and that dirt acts as sandpaper which causes the screw head to wear faster and eventually strip.

Chances are the chassis is so thin that it needs to be replaced anyway, but most folks will keep running the chassis until it eventually snaps

Chances are the chassis is so thin that it needs to be replaced anyway, but most folks will keep running the chassis until it eventually snaps

WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,949

- Reaction score

- 21,185

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

Yeah, I have seen more than my share of worn down screws