Susquehanna River Rat

RCTalk Rookie

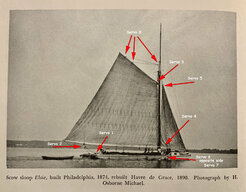

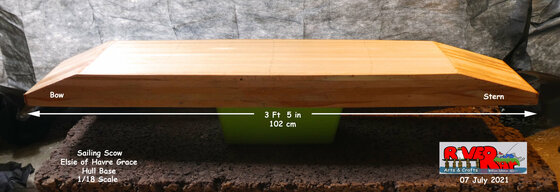

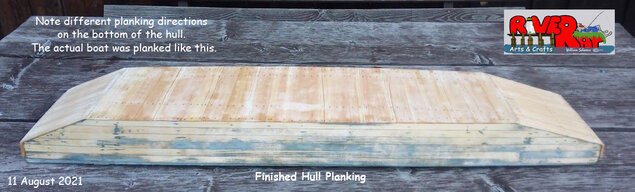

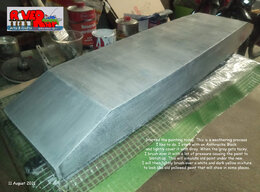

I am currently working on a 1/18 scale, scratch built, wooden model of The Chesapeake Bay Sailing Scow "Elsie of Havre de Grace" and want to install RC equipment in the boat to operate everything. I have little experience with RC but with a little help, I am sure I can make this work........can't I ?

So here goes...

Servo 1. Rudder (easy)

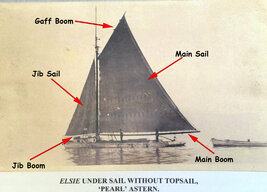

Servo 2. Main Boom (Winder type) The main boom will be free floating and operate like the real one. The servo line will let out and bring in the boom to trim the main sail.

Servo 3. Main Sail (Winder type) Raising and lowering the main sail. This line will be attached to the Gaff to raise and lower the main sail. This could also be used to trim the sails. Not sure if it will work or not but it should.

Servo 4. Jib Boom (Winder type) Like Servo 2 but but for the Jib Sail Boom.

Servo 5. Jib Sail (Winder type) Like Servo 3 but for the Jib Sail

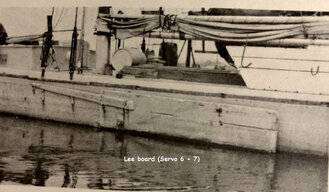

Servo 6. Starboard Lee Board. Because the boat is flat bottomed and does not have a keel like normal sail boats, it utilized what are called "Lee Boards". These are mounted on the sides of the boat and only one of them (the "Leeward" or downwind side Lee Board is in the water. The upwind lee board is raised.) I am not sure how to attach them to the servo.

A direct attachment or probably better a belt or chain drive. The just need to go up and down a short way.

Servo 7. Same as Servo 6 but Port side.

Servo 8. Gaff Boom (Winder type) This Servo operates to make adjustments lifting the outer end of the Gaff Boom. This will tighten or loosen the outer edge of the main sail.

Again, this is what I would like to put in the boat. My question is, what do I need to make all of this work. There is enough room in the boat, about 3 1/2 ft long, for the equipment but still, if there are small servos out there, I would prefer installing them. I have added a few photos of the original "Elsie" so you can see what I mean from the description above.

Thanks in advance for the help.

So here goes...

Servo 1. Rudder (easy)

Servo 2. Main Boom (Winder type) The main boom will be free floating and operate like the real one. The servo line will let out and bring in the boom to trim the main sail.

Servo 3. Main Sail (Winder type) Raising and lowering the main sail. This line will be attached to the Gaff to raise and lower the main sail. This could also be used to trim the sails. Not sure if it will work or not but it should.

Servo 4. Jib Boom (Winder type) Like Servo 2 but but for the Jib Sail Boom.

Servo 5. Jib Sail (Winder type) Like Servo 3 but for the Jib Sail

Servo 6. Starboard Lee Board. Because the boat is flat bottomed and does not have a keel like normal sail boats, it utilized what are called "Lee Boards". These are mounted on the sides of the boat and only one of them (the "Leeward" or downwind side Lee Board is in the water. The upwind lee board is raised.) I am not sure how to attach them to the servo.

A direct attachment or probably better a belt or chain drive. The just need to go up and down a short way.

Servo 7. Same as Servo 6 but Port side.

Servo 8. Gaff Boom (Winder type) This Servo operates to make adjustments lifting the outer end of the Gaff Boom. This will tighten or loosen the outer edge of the main sail.

Again, this is what I would like to put in the boat. My question is, what do I need to make all of this work. There is enough room in the boat, about 3 1/2 ft long, for the equipment but still, if there are small servos out there, I would prefer installing them. I have added a few photos of the original "Elsie" so you can see what I mean from the description above.

Thanks in advance for the help.