- Messages

- 1,486

- Reaction score

- 2,611

- Location

- Iowa

- RC Driving Style

- Racing

- Crawling

- Scale Builder

- Flying

I spent the weekend in the shop working on suspension stuff. As I build and modified different rigs I have two rigs that are my best. One has Capra axles and one has AR44 straight axles. The Capra based rig is superior in most cases. But it is really close. Both have servo on axle.

My other rig is just kinda average. I built it with AR45 axles and a 3 gear. It climbs OK and definitely has good ground clearance but it’s top heavy.

So I decided to give it some love. This whole process took about twenty hours. I have to balance the servo, ESC and battery location along with the suspension geometry and drive line. Every change messes up two of the other things.

I removed the shocks and got the suspension sorted. First I got the wheel base is the same on both sides. Next the pan hard rod was binding. And the steering links was at a bad angle.

I tried three different pan had link mounts but the pumpkin on the left was totally in the way and the servo on the left was a total mess. I finally, after testing each change one thing at a time mounted the panhard rod forward of the differential. That allowed the frame to drop all the way down to the axle. I then mounted a lay down servo mount to get the linkage up away from the panhard. This also keeps everything parallel. Next I mounted a set of 90mm desert lizards. The first tests were great in some areas but it just kept falling over. The weight balance is 57/43 and no body yet.

So I switched to 80mm shocks and now it has no articulation.

It is 10mm lower and does much better at side hilling but struggles with the center skid dragging on break overs.

So now I’m thinking about going back to a set of AR44s. I want to like the AR45. I got them moving properly but performance is not even close to the others.

Pictures tonight.

My other rig is just kinda average. I built it with AR45 axles and a 3 gear. It climbs OK and definitely has good ground clearance but it’s top heavy.

So I decided to give it some love. This whole process took about twenty hours. I have to balance the servo, ESC and battery location along with the suspension geometry and drive line. Every change messes up two of the other things.

I removed the shocks and got the suspension sorted. First I got the wheel base is the same on both sides. Next the pan hard rod was binding. And the steering links was at a bad angle.

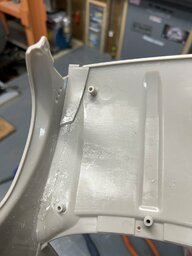

I tried three different pan had link mounts but the pumpkin on the left was totally in the way and the servo on the left was a total mess. I finally, after testing each change one thing at a time mounted the panhard rod forward of the differential. That allowed the frame to drop all the way down to the axle. I then mounted a lay down servo mount to get the linkage up away from the panhard. This also keeps everything parallel. Next I mounted a set of 90mm desert lizards. The first tests were great in some areas but it just kept falling over. The weight balance is 57/43 and no body yet.

So I switched to 80mm shocks and now it has no articulation.

It is 10mm lower and does much better at side hilling but struggles with the center skid dragging on break overs.

So now I’m thinking about going back to a set of AR44s. I want to like the AR45. I got them moving properly but performance is not even close to the others.

Pictures tonight.