corneileous

RCTalk Champion

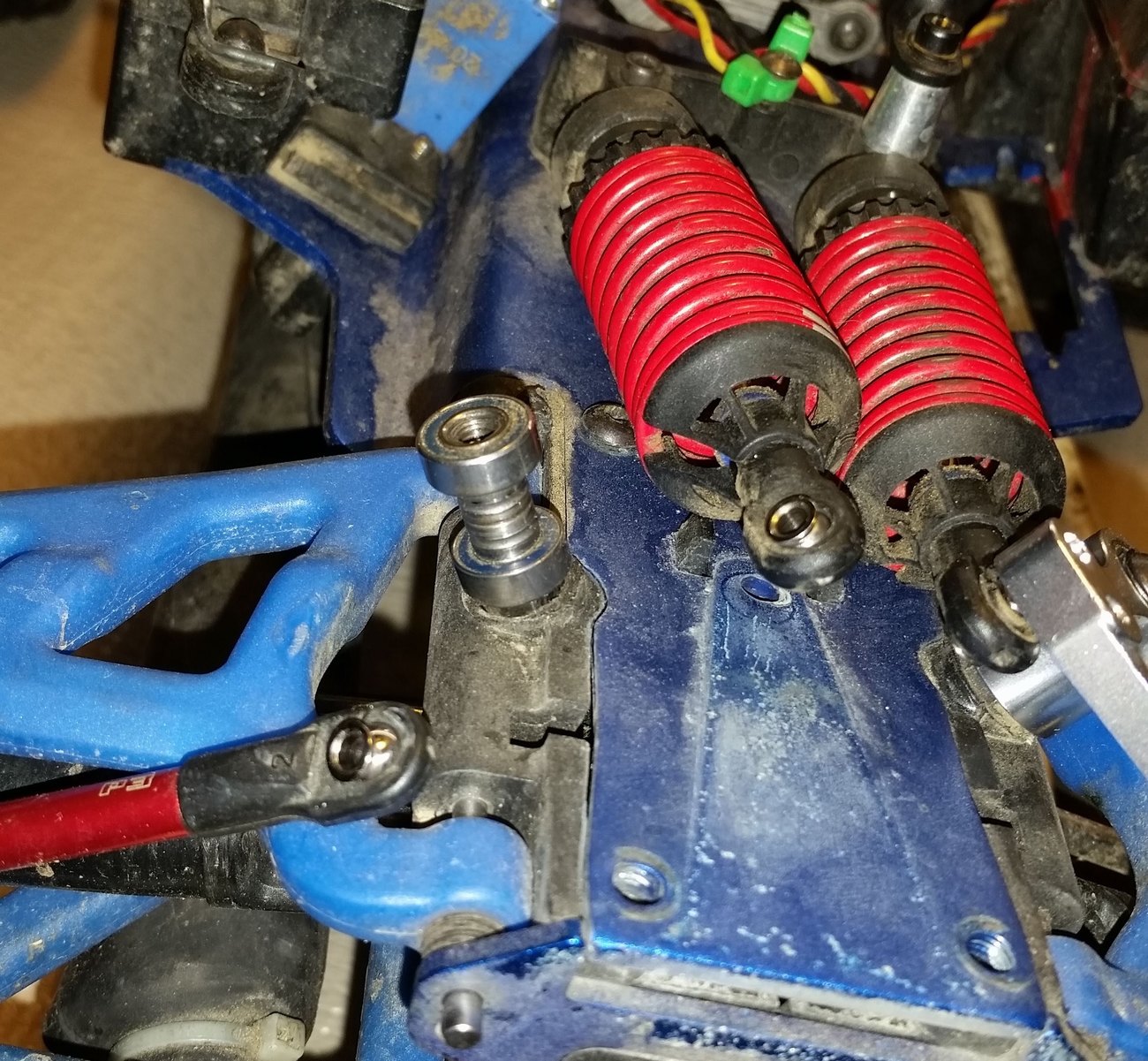

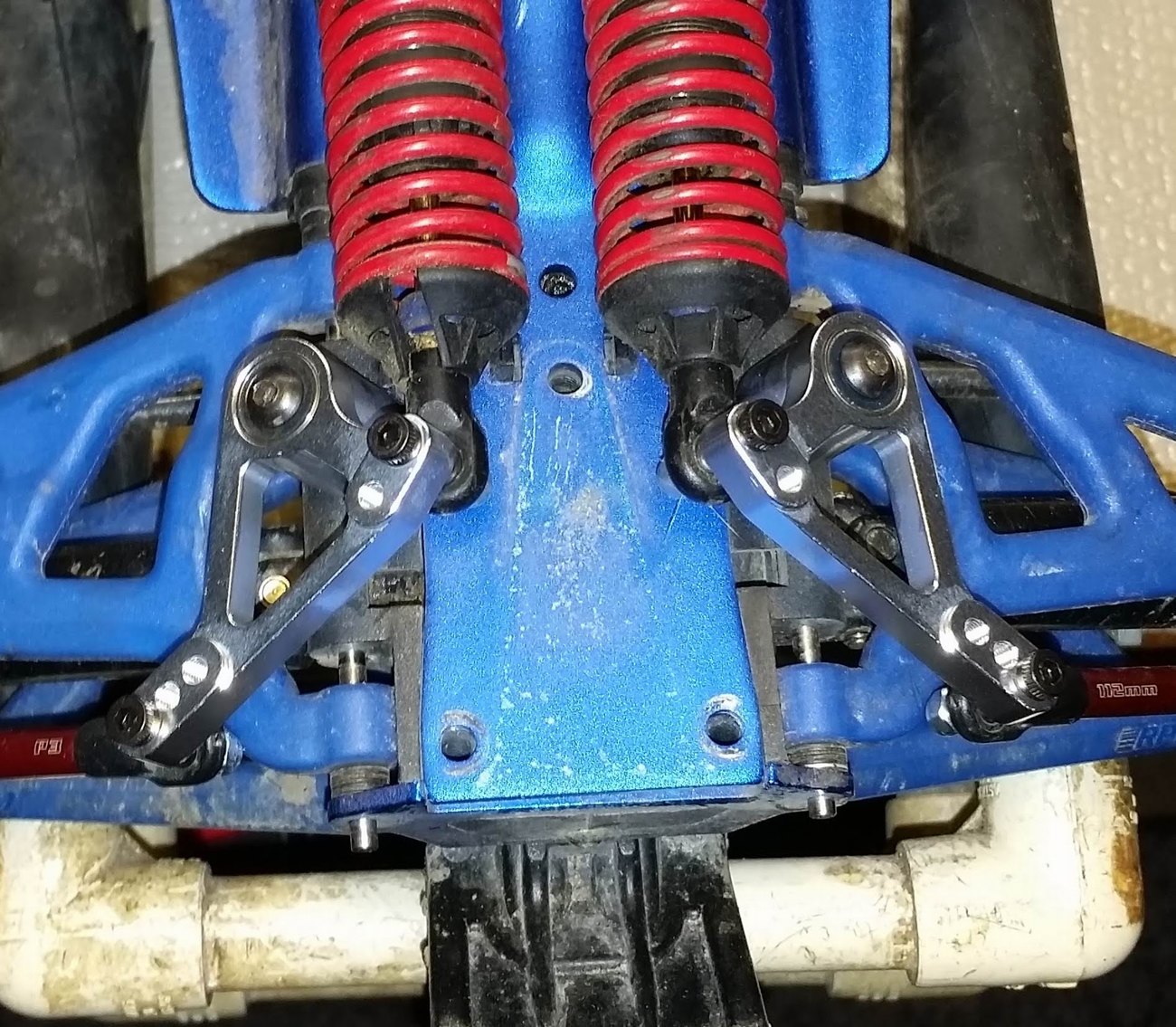

Just noticed I had a lot of play in pretty much all four of my shocks, some being worse than others, where the shocks and the rocker arms come together. I don’t race my truck nor do I bash it all that hard but there’s quite a bit of slack in most of them. Even a little bit of slack on the other end where they attach to the chassis with most of being on the rocker end.

I’m assuming my much stiffer springs and 50w shock oil might be contributors but where can find some stronger aluminum rod ends and shock caps? Thanks.

I’m assuming my much stiffer springs and 50w shock oil might be contributors but where can find some stronger aluminum rod ends and shock caps? Thanks.