corneileous

RCTalk Champion

- Thread starter

- #21

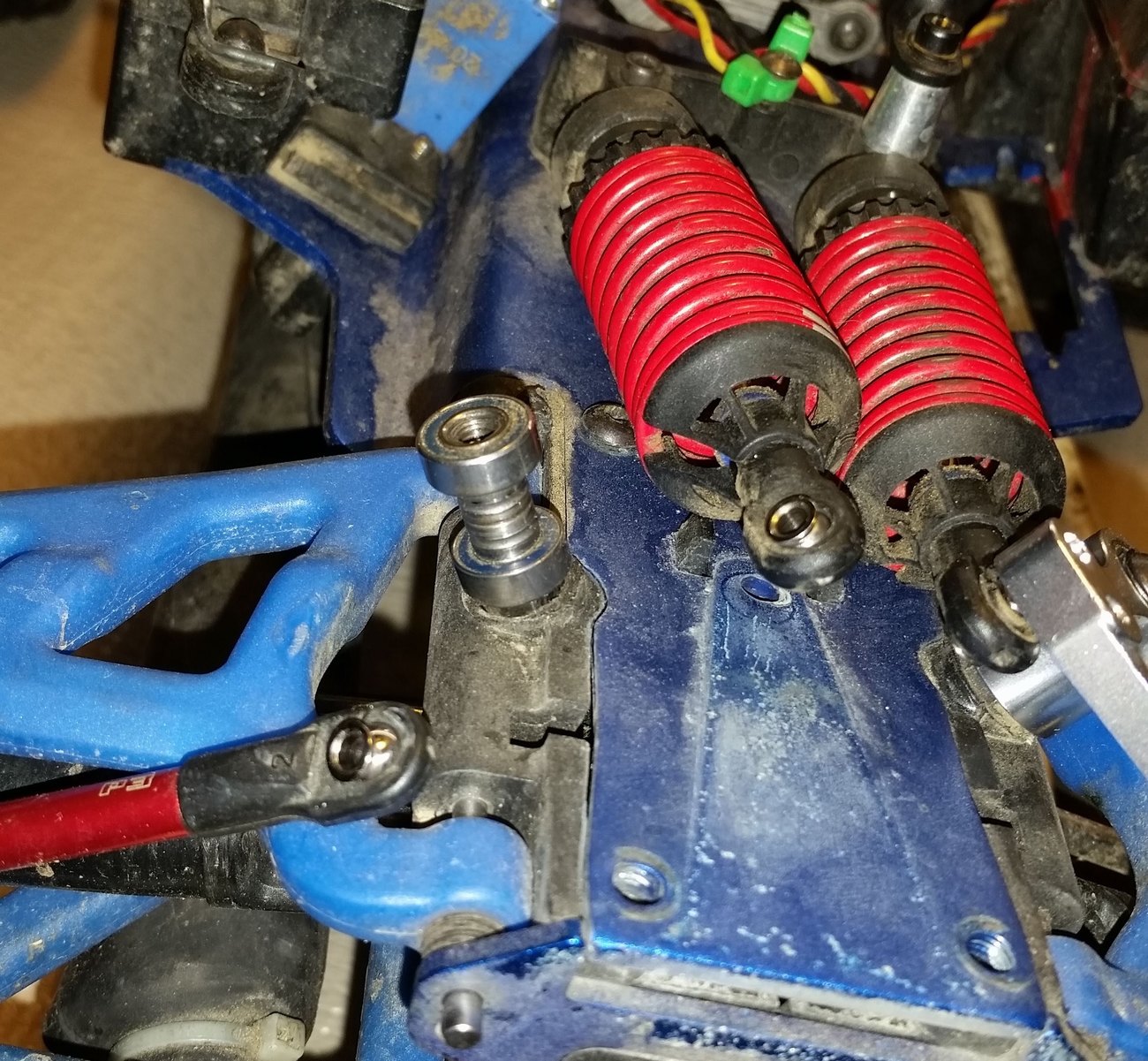

But hey, since were talking about shocks an aftermarket shocks, I have a question that I can’t get cleared up about the different options of springs that come with those hot racing shock absorber sets that that I ordered.

I’m trying to figure out how the blue springs that I think will come pre-mounted on the shock absorbers and the chrome plated springs that come as an option are compared to the Traxxas cool springs because the pound rating or whatever it is that hot racing uses to describe their blue with their silver rings does not seem to be the same as how Traxxas describes the spring rates of their springs.

Example given, I run the tan Traxxas springs on the back which are 23.4 lb/in (4.1 N/mm) and the gold springs; 21.7 lb/in (3.8 N/mm) on the front. Hot Racing says their chrome stiff springs are a 6.8lb rate and their blue medium springs are a 4.2lb rate. The guy at hobby ECT who sold me the shocks said that the chrome springs are a lot stiffer than even the 90 mm black springs for the Revo 3.3 but their medium blue Springs, I think he said were somewhere between the gold and the tan traxxas springs. How is he (or hot racing) coming up with those numbers because the numbers that Traxxas uses is obviously not the same numbers that hot Racing uses to define their springs?

I’m trying to figure out how the blue springs that I think will come pre-mounted on the shock absorbers and the chrome plated springs that come as an option are compared to the Traxxas cool springs because the pound rating or whatever it is that hot racing uses to describe their blue with their silver rings does not seem to be the same as how Traxxas describes the spring rates of their springs.

Example given, I run the tan Traxxas springs on the back which are 23.4 lb/in (4.1 N/mm) and the gold springs; 21.7 lb/in (3.8 N/mm) on the front. Hot Racing says their chrome stiff springs are a 6.8lb rate and their blue medium springs are a 4.2lb rate. The guy at hobby ECT who sold me the shocks said that the chrome springs are a lot stiffer than even the 90 mm black springs for the Revo 3.3 but their medium blue Springs, I think he said were somewhere between the gold and the tan traxxas springs. How is he (or hot racing) coming up with those numbers because the numbers that Traxxas uses is obviously not the same numbers that hot Racing uses to define their springs?