Nosweat

RCTalk Basher

- Thread starter

- #21

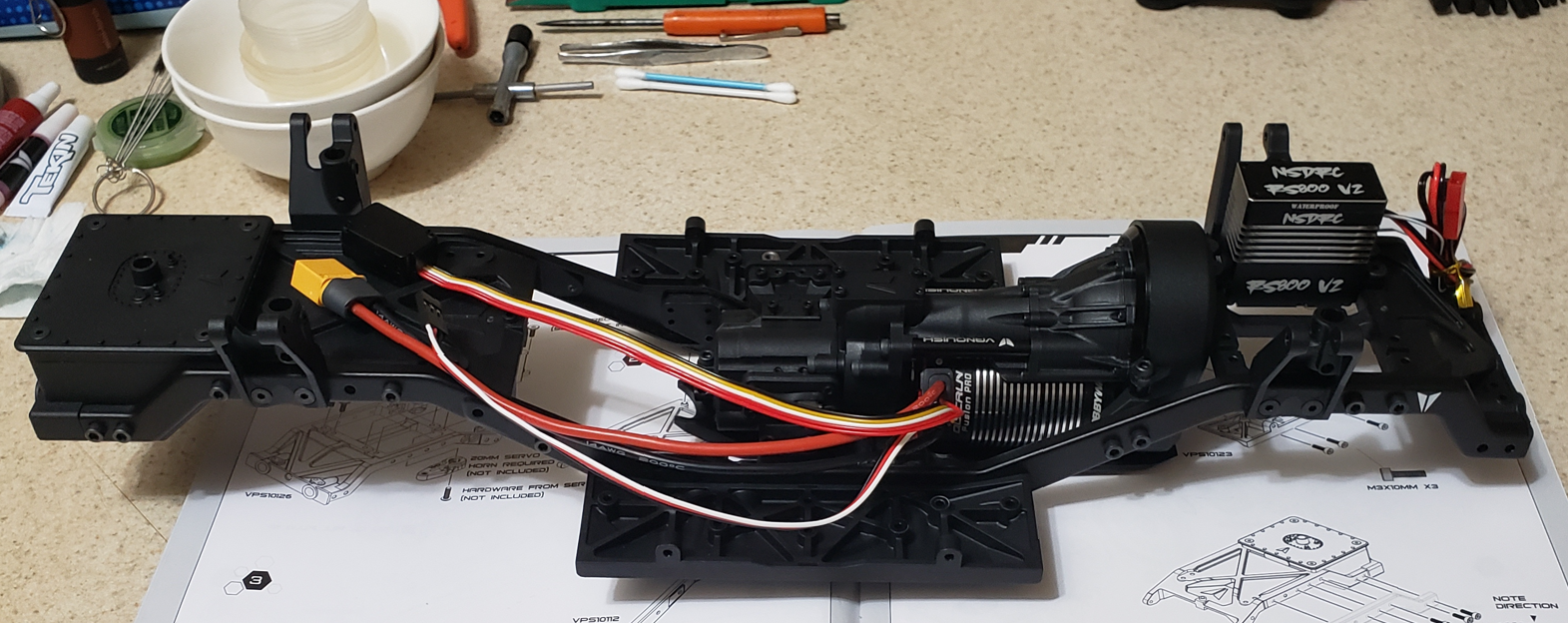

Finished the motor/tranny, had a little modding to do. The front right top link mount had to be sanded a little to except the 37mm can. I also installed my RS800 V2 steering servo.

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Thanks. Today I'm going to unsolder my Fusion Pro XT60 plug and replace it with a IC5 plug, I use Spektrum smart batteries and don't want to use a adaptor. I'm also going to wire in a RCY JST plug to it, so I can plug in my direct power servo. I have finished and installed my motor/tranny and servo. Sorry about double photo, forgot about page two.It's tough to beat Vanquish stuff, awesome build.

Thanks. Finally ordered hubs and center caps for my Phoenix portal. I'll have my axles and shocks installed on my straight axle today.Nice bit of improvising.

Those are going to look great on there!Ordered some nice wheels and hubs from Gmade. I've also decided to paint my body dessert sand.

View attachment 162163

View attachment 162164

Thanks, but it may be a while before I get back to my custom flatbed. I want to finish up both of my VP Phoenix's first. My Phoenix portal will be finished up today as a matter of fact. Hubs and center caps for it came today, haven't opened the package yet just woke up and am having my first cup of coffee. When I get my wheels for my straight axle, I may have a problem. I think the stock 12mm hexes will not fit the wheels. The 12mm hexes are stepped down and I don't think the wheels are stepped down on the inside. That is easily remedied by getting Gmade clamp type aluminum 12mm wheel hexes like these. I'll have to get the wheels first so I can decide what size to get, they come in 4, 5, 6, 8 and 10mm. I don't want to run into the same issue that you do with portal axles needing longer SLW hubs to mount the wheels. This being a straight axle I shouldn't have that issue but you never know.Those are going to look great on there!

Can't wait to see the rear suspension setup. I am a sucker for cantilevers

Thanks. Now I'm building another one for my portal.Box came out nice.