- Thread starter

- #41

Quick update

Hobby Town Colorado Springs

I was out of town last week and didn't get much done. Big shout out to Hobby Town in Colorado Springs! I always drop in when I'm in the area it's a real hobby store with real employees that don't mind helping with Frankenstein projects. Don't get me wrong, I love Norcal hobbies but it's a bit hectic to get any ones attentions sometimes and it's about 1/4 the size of the Hobby Town.

Hub Conversion Update

My super glue on the broken hub, looks to be solid which is a good sign. Polyethylene can be very difficult to glue and not knowing what type of plastic it is, I took a shot in the dark and got lucky. Just know that you can glue the parts.

While I was out of town was able to score some Traxxas 4-tec hubs (thanks HT). They about 2mm shorter than the Rlaarlo hub but fit just fine. I can add 2mm spacer to the top or bottom and adjust the ride height as well, or split the difference and add 1mm to both. I have spacers coming.

The steering links are within adjustment range and it looks like the steering arm clears the wheels. ... so far.

They drive shaft are still a bit of a mystery. I ordered the Traxxas drive shafts with CVDs. The factory front axle is 55mm. Scaling the Traxxas drive shaft picture it looks like they are ~40mm long, but the drive cups is about 1/2" longer too. So I "think" the axles will be pretty close and might work, but if not I can order some that are different lengths. HB racing, HPI and others have the lengths listed on the Amain website.

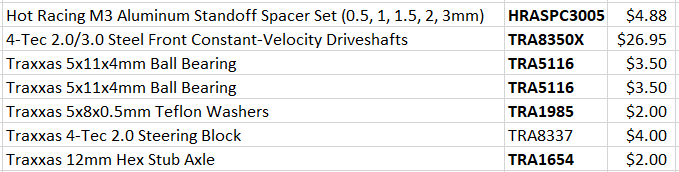

The bearings, shims and Traxxas 12mm hexes (see above) are also ordered.

The current list of parts to convert to Traxxas 4-tec hubs is below. It may change.

Top Plate

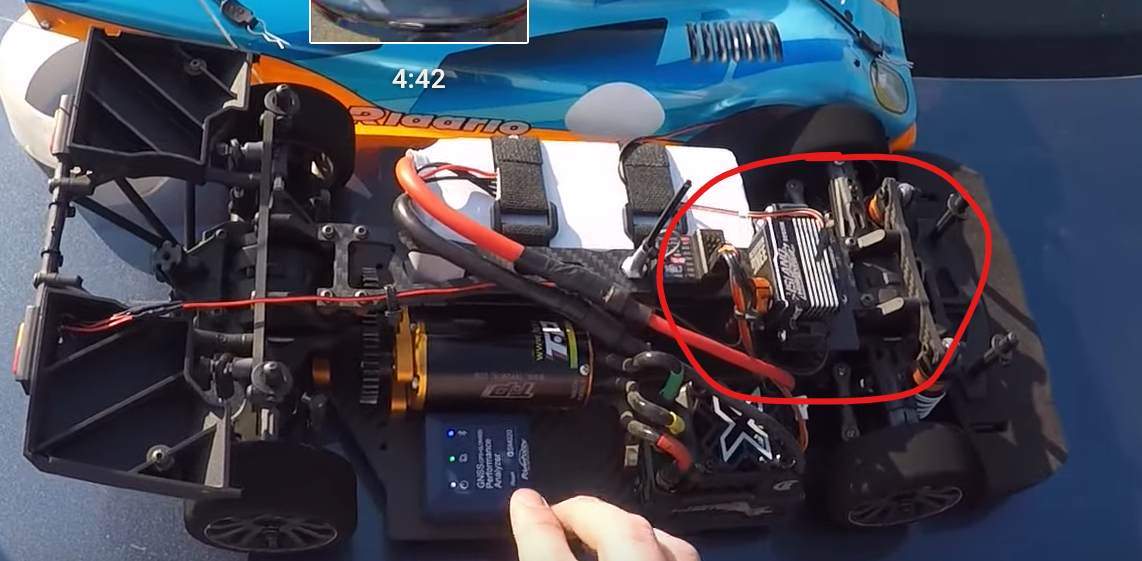

I really don't like the servo on floor were it is. After watching John linneman videos, he mounted the servo on the top brace. This is his car from the video.

This is his car from the video.

That's a great idea and I'm going to work on that as well. The aluminum stock for the plate is ordered. The servo, receiver and antennas will be mounted there. @Dan B. Thanks for the link to antenna mount - also ordered.

I also have a new servo to replace the monster that's on there now. It's a low profile ProTek RC 140T Low Profile servo the 370T BL that I have now is just too much servo also the lower profile will save some room.

Taller Shocks

The end to end shock height is taller in the rear by about 1/4" (6mm). Which put less preload on the rear and makes it soft. Normally you want the back softer than the front to avoid becoming an oversteer machine. But we are going straight... hopefully.

My idea, we will see how this works, is to replace the rod ends with taller ones. I ordered the Traxxas TRA5525 rod ends. They look to be much longer than the stock one and we will see if they fit and if it helps the suspension.

This is roughly scaled and appear to be about twice a long. They are just plastic and can be shorted with a sander if I need to.

Hobby Town Colorado Springs

I was out of town last week and didn't get much done. Big shout out to Hobby Town in Colorado Springs! I always drop in when I'm in the area it's a real hobby store with real employees that don't mind helping with Frankenstein projects. Don't get me wrong, I love Norcal hobbies but it's a bit hectic to get any ones attentions sometimes and it's about 1/4 the size of the Hobby Town.

Hub Conversion Update

My super glue on the broken hub, looks to be solid which is a good sign. Polyethylene can be very difficult to glue and not knowing what type of plastic it is, I took a shot in the dark and got lucky. Just know that you can glue the parts.

While I was out of town was able to score some Traxxas 4-tec hubs (thanks HT). They about 2mm shorter than the Rlaarlo hub but fit just fine. I can add 2mm spacer to the top or bottom and adjust the ride height as well, or split the difference and add 1mm to both. I have spacers coming.

The steering links are within adjustment range and it looks like the steering arm clears the wheels. ... so far.

They drive shaft are still a bit of a mystery. I ordered the Traxxas drive shafts with CVDs. The factory front axle is 55mm. Scaling the Traxxas drive shaft picture it looks like they are ~40mm long, but the drive cups is about 1/2" longer too. So I "think" the axles will be pretty close and might work, but if not I can order some that are different lengths. HB racing, HPI and others have the lengths listed on the Amain website.

The bearings, shims and Traxxas 12mm hexes (see above) are also ordered.

The current list of parts to convert to Traxxas 4-tec hubs is below. It may change.

Top Plate

I really don't like the servo on floor were it is. After watching John linneman videos, he mounted the servo on the top brace.

That's a great idea and I'm going to work on that as well. The aluminum stock for the plate is ordered. The servo, receiver and antennas will be mounted there. @Dan B. Thanks for the link to antenna mount - also ordered.

I also have a new servo to replace the monster that's on there now. It's a low profile ProTek RC 140T Low Profile servo the 370T BL that I have now is just too much servo also the lower profile will save some room.

Taller Shocks

The end to end shock height is taller in the rear by about 1/4" (6mm). Which put less preload on the rear and makes it soft. Normally you want the back softer than the front to avoid becoming an oversteer machine. But we are going straight... hopefully.

My idea, we will see how this works, is to replace the rod ends with taller ones. I ordered the Traxxas TRA5525 rod ends. They look to be much longer than the stock one and we will see if they fit and if it helps the suspension.

This is roughly scaled and appear to be about twice a long. They are just plastic and can be shorted with a sander if I need to.