The Build List

Rlaarlo 1/10 Carbon Fiber On-Road Cars 200km/h Roller

TP POWER 3640

CONTACT J13773 26mm

Castle Creations Mamba Monster 8S

4S Battery & QS8 Connectors

Why are You Building This?

Some say I'm smart, others say I'm stupid or it maybe it's just poor life choices? In reality this build started from a video I saw from Tomely RC, called "Rlaarlo's NEW 100mph RC Car is So Cheap on Pre sale!"

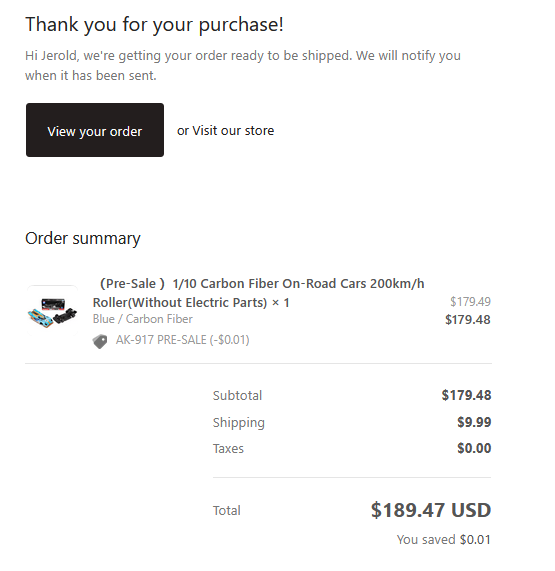

I had never took Rlaarlo seriously, but it looked interesting and fairly inexpensive too. Spoiler - I didn't do all the math. Eventually, I saw a few more videos then my speed running buddies on Arrama Forums got into the game, so I purchased the Rlaarlo AK-917 CF roller. I was second on that thread to buy one and I was the first to get it.

Eventually, I saw a few more videos then my speed running buddies on Arrama Forums got into the game, so I purchased the Rlaarlo AK-917 CF roller. I was second on that thread to buy one and I was the first to get it.

This is a bit of adventure to do something brand new. As a side note, even though this started in the Arrma Forums, @WoodiE runs both forums and is very cool to let us play in the Arrma sandbox with other brands; I thought it would be appropriate to do the Rlaarlo build here.

What Will You Do To It?

Being brand new and from a small company is a bit of a challenge to get a plan. No one has built one before and none of the specs for the motor size, gear pitch, wheel hex, etc were published and it was an adventure to find the information. The good news is if you have questions and email them, the do get back to you the next day. Which is better than most US manufacturers.

Through several other videos and hours of research, I managed to figure out the max diameter of the motor was 36mm, thanks to Francis at RC Review. He had a good angle that I could see the 36mm can was flat on the chassis. Bars&Tones RC swapped the wheels for foam and I was able to see the hex size. The gear pitch appeared somewhere in the website at some point. Also Rlaarlo started to give a few more details on their website.

The Mock Up

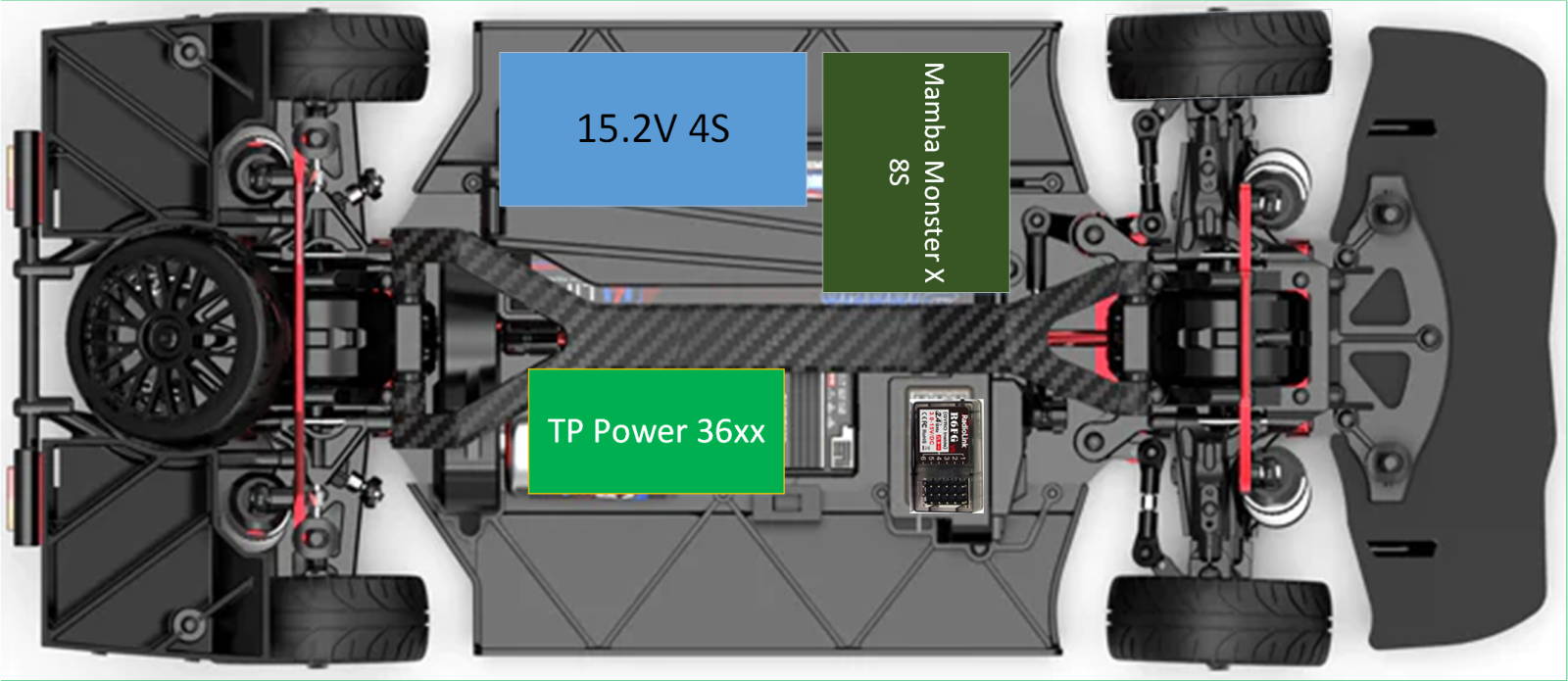

To get some ideas I took the pic from the Rlaarlo website and scaled it in Visio to full size. Then started placing scale blocks of different components.

I went through a few iterations. Other's are stuffing the XLX2 in there which is an awesome ESC, but I did some back flips on the limitless to make everything fit gracefully and took the easy path on this one. It gets the MMX 8S ESC with a 4S battery and TP 36xx series motor. The basic layout I decided on is below.

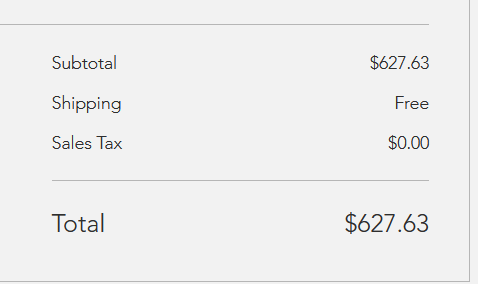

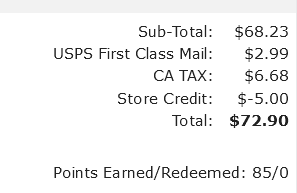

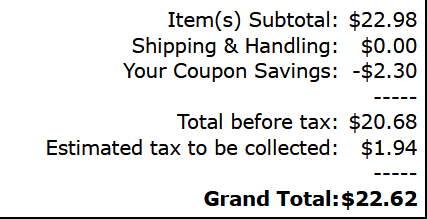

When the shipping notice arrived, I made an order to Island Hobby, Amain and Amazon. THIS is the math I didn't do. So my $200 roller is now about $1K. Don't tell my wife, or she will get another Louis Vuitton.

So my $200 roller is now about $1K. Don't tell my wife, or she will get another Louis Vuitton.

Out of the box

It looks like good quality. The CF is smooth and fairly ridged. The pit fall is the HW. It looks like some of the hexes are buggered, but they just made that way. Maybe the manufacture has a crappy swage or they are the 2nds for batches. I don't know but I will eventually be replacing the HW with better stuff as I go through it. I use good tools but stuff happens and better quality HW makes a huge difference on the frustration scale and it's worth $20 and a it of effort.

When I pulled it apart there was thread lock on the metal-metal screws, which a bit of heat fixed. I used a soldering iron on the head which seems to work. You can use a torch, which is normally my preferred method, but you need to be careful of the carbon fiber.

The shocks feel decent but the springs are way too soft. The book that comes with it says they are 28mm x 65mm, so I'm hopping to find something that will fit. They will be getting some sort of limiter, otherwise it will just chassis slap on everything.

An added bonus is it comes with the lights and body fan. I don't care about the blinkers or exhaust, but just having head and tail lights make it easier to see at a distance.

The center spool shaft is 5mm and @LibertyMKiii and confirmed you can put a Mod 1 gear set in there. I'll be running the 48P gears for now, but will eventually move to Mod 1. If you are thinking about it, do the math to make sure they fit.

The Real Layout

This is the first pass at the fit and I've got plenty of room. Just pulled the battery tray. Unfortunately, the servo is right where I want to put the ESC. Since I don't want to drill holes and move the servo it's getting this layout for now.

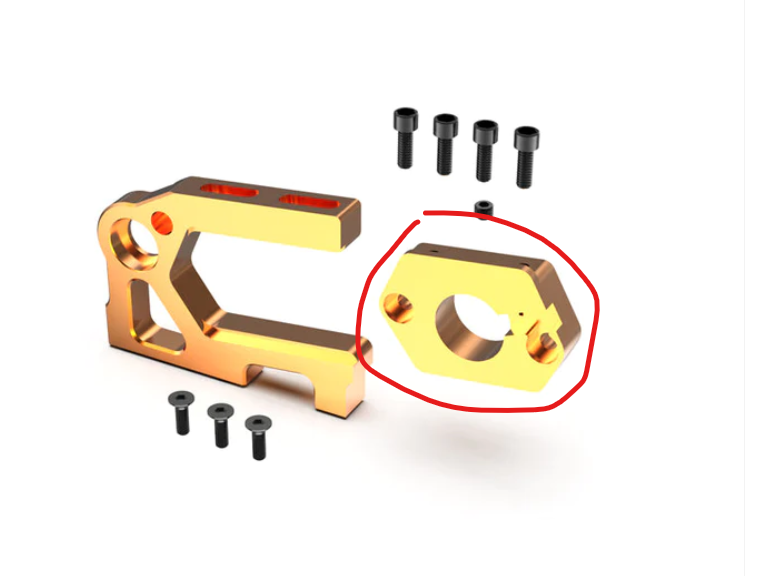

I delayed putting it together because I thought I was missing a piece.

However, it turns out I wasn't paying attention and it's a different mount.... which is the one that is a total pain in the butt to get mounted with the correct mesh. I have the sliding mount ordered.

Mounting the Motor and Adjusting the Pinion

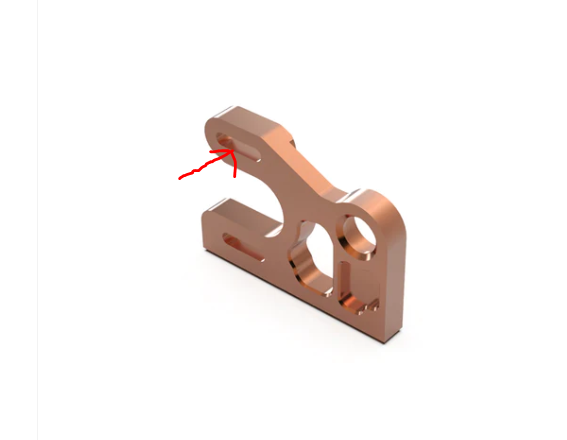

To get the gear mesh correct it's a bit tricky. This is how I did it. First thing is I pulled center brace. Then remove the back cage and wing support. Two screws on the shock tower and two in the back. The longer screws go in the back.

Leave the pinion off for now. With the back removed you can get a driver to the front of the motor mount between the control arms. It's not exactly aligned so be careful. Also the mount has recesses for the screw heads and they are M3x(shorter than I thought). Make sure your screws aren't too long and get into the motor. I snugged them up to keep it in place but could still move the motor a bit. Then slipped the pinion on the front and nudge the motor until the mesh was correct. Then re-tighten the screws. Then added thread lock, by removing them one at a time without moving the motor. The last step is to slide the pinion on from the front. Like I said it's a pain in the butt.

Another note on this is the shaft of the TP motors touches the gear cover, which you will probably want to keep, and I had to create some space on the plastic cover. The reason I decided to keep it is that it's next to the battery and would make a nice saw if there was a crash where the battery moved.

More to come. . .

Rlaarlo 1/10 Carbon Fiber On-Road Cars 200km/h Roller

TP POWER 3640

CONTACT J13773 26mm

Castle Creations Mamba Monster 8S

4S Battery & QS8 Connectors

Why are You Building This?

Some say I'm smart, others say I'm stupid or it maybe it's just poor life choices? In reality this build started from a video I saw from Tomely RC, called "Rlaarlo's NEW 100mph RC Car is So Cheap on Pre sale!"

I had never took Rlaarlo seriously, but it looked interesting and fairly inexpensive too. Spoiler - I didn't do all the math.

This is a bit of adventure to do something brand new. As a side note, even though this started in the Arrma Forums, @WoodiE runs both forums and is very cool to let us play in the Arrma sandbox with other brands; I thought it would be appropriate to do the Rlaarlo build here.

What Will You Do To It?

Being brand new and from a small company is a bit of a challenge to get a plan. No one has built one before and none of the specs for the motor size, gear pitch, wheel hex, etc were published and it was an adventure to find the information. The good news is if you have questions and email them, the do get back to you the next day. Which is better than most US manufacturers.

Through several other videos and hours of research, I managed to figure out the max diameter of the motor was 36mm, thanks to Francis at RC Review. He had a good angle that I could see the 36mm can was flat on the chassis. Bars&Tones RC swapped the wheels for foam and I was able to see the hex size. The gear pitch appeared somewhere in the website at some point. Also Rlaarlo started to give a few more details on their website.

The Mock Up

To get some ideas I took the pic from the Rlaarlo website and scaled it in Visio to full size. Then started placing scale blocks of different components.

I went through a few iterations. Other's are stuffing the XLX2 in there which is an awesome ESC, but I did some back flips on the limitless to make everything fit gracefully and took the easy path on this one. It gets the MMX 8S ESC with a 4S battery and TP 36xx series motor. The basic layout I decided on is below.

When the shipping notice arrived, I made an order to Island Hobby, Amain and Amazon. THIS is the math I didn't do.

Out of the box

It looks like good quality. The CF is smooth and fairly ridged. The pit fall is the HW. It looks like some of the hexes are buggered, but they just made that way. Maybe the manufacture has a crappy swage or they are the 2nds for batches. I don't know but I will eventually be replacing the HW with better stuff as I go through it. I use good tools but stuff happens and better quality HW makes a huge difference on the frustration scale and it's worth $20 and a it of effort.

When I pulled it apart there was thread lock on the metal-metal screws, which a bit of heat fixed. I used a soldering iron on the head which seems to work. You can use a torch, which is normally my preferred method, but you need to be careful of the carbon fiber.

The shocks feel decent but the springs are way too soft. The book that comes with it says they are 28mm x 65mm, so I'm hopping to find something that will fit. They will be getting some sort of limiter, otherwise it will just chassis slap on everything.

An added bonus is it comes with the lights and body fan. I don't care about the blinkers or exhaust, but just having head and tail lights make it easier to see at a distance.

The center spool shaft is 5mm and @LibertyMKiii and confirmed you can put a Mod 1 gear set in there. I'll be running the 48P gears for now, but will eventually move to Mod 1. If you are thinking about it, do the math to make sure they fit.

The Real Layout

This is the first pass at the fit and I've got plenty of room. Just pulled the battery tray. Unfortunately, the servo is right where I want to put the ESC. Since I don't want to drill holes and move the servo it's getting this layout for now.

I delayed putting it together because I thought I was missing a piece.

However, it turns out I wasn't paying attention and it's a different mount.... which is the one that is a total pain in the butt to get mounted with the correct mesh. I have the sliding mount ordered.

Mounting the Motor and Adjusting the Pinion

To get the gear mesh correct it's a bit tricky. This is how I did it. First thing is I pulled center brace. Then remove the back cage and wing support. Two screws on the shock tower and two in the back. The longer screws go in the back.

Leave the pinion off for now. With the back removed you can get a driver to the front of the motor mount between the control arms. It's not exactly aligned so be careful. Also the mount has recesses for the screw heads and they are M3x(shorter than I thought). Make sure your screws aren't too long and get into the motor. I snugged them up to keep it in place but could still move the motor a bit. Then slipped the pinion on the front and nudge the motor until the mesh was correct. Then re-tighten the screws. Then added thread lock, by removing them one at a time without moving the motor. The last step is to slide the pinion on from the front. Like I said it's a pain in the butt.

Another note on this is the shaft of the TP motors touches the gear cover, which you will probably want to keep, and I had to create some space on the plastic cover. The reason I decided to keep it is that it's next to the battery and would make a nice saw if there was a crash where the battery moved.

More to come. . .

I was able to center the servo. removing the front nose piece makes all of this stuff much easier!

I was able to center the servo. removing the front nose piece makes all of this stuff much easier!