WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,924

- Reaction score

- 21,117

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

@Greywolf, @johnnydmd, and myself are on a mission to design the ultimate RC car stand. One that will hold anything securely from 1:10 scale to 1:8 scale. So here are the design stages. Additional features not yet completed are a shock stand, and possibly a tool stand. Other possible "out there" ideas are a clock, Bluetooth speakers, gooseneck LED light, etc. Any suggestions? I figure we could power it off a LiPo battery if we do add any electronics to it

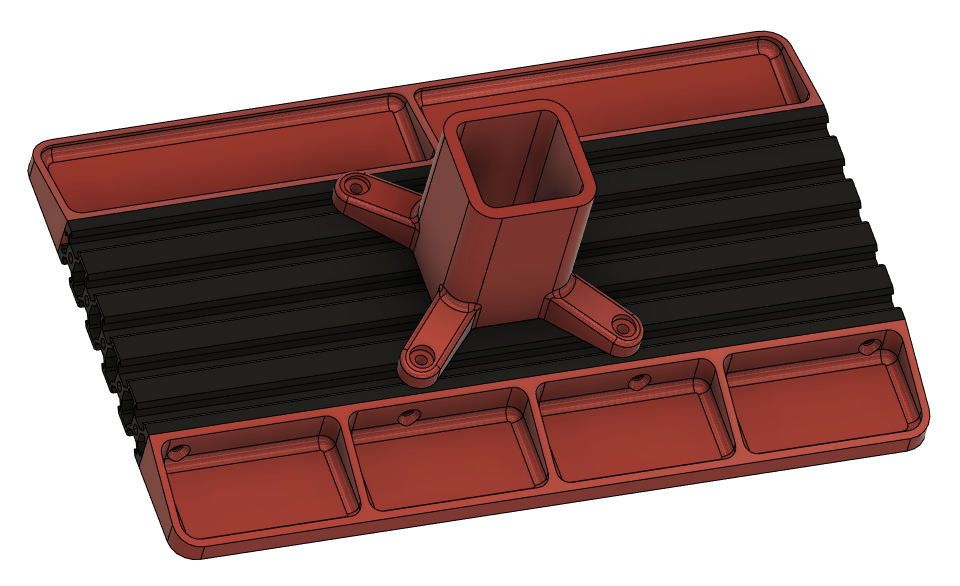

20mm x 100mm x 300mm aluminum extrusion for the base, with front and rear parts trays.

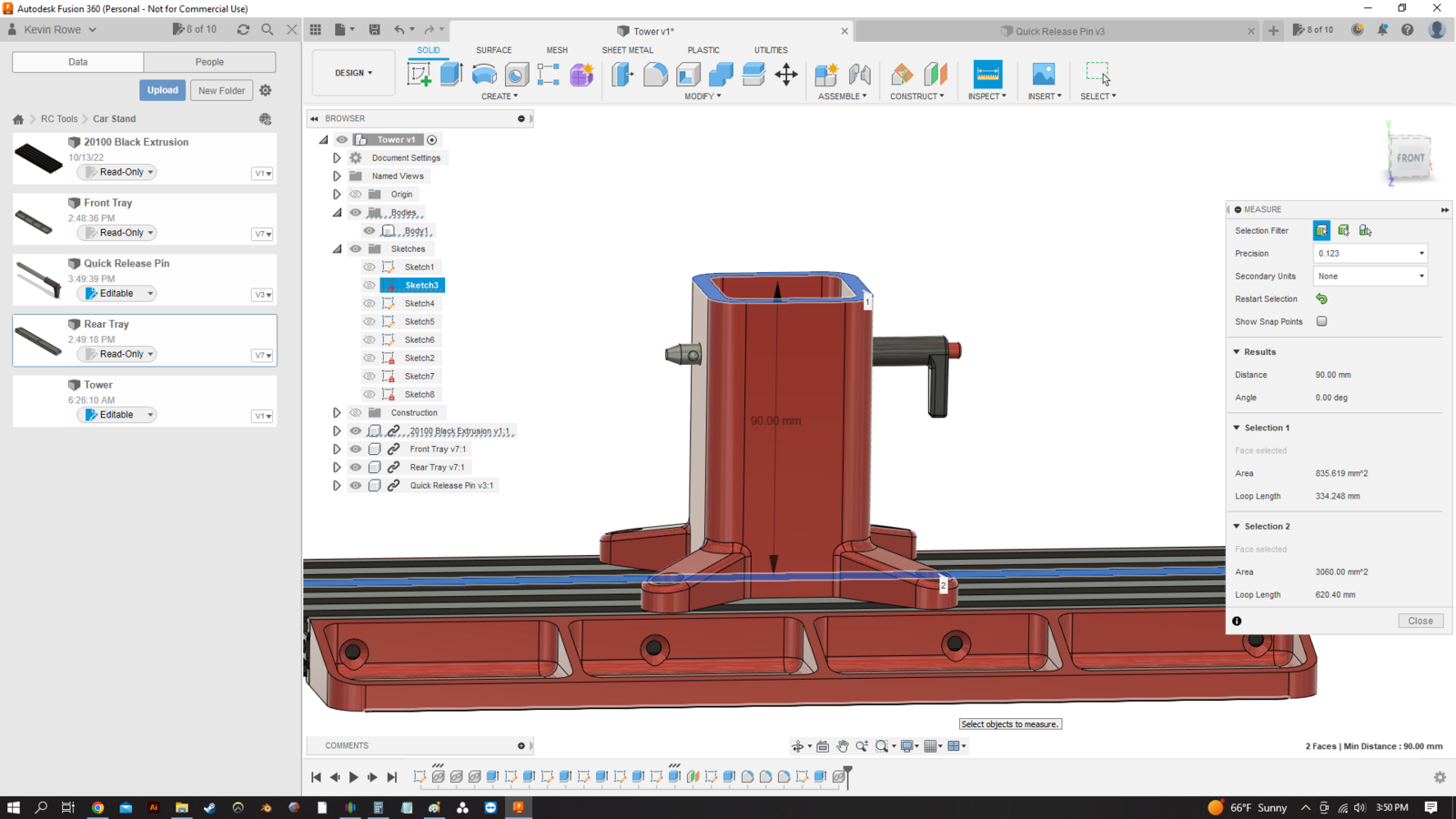

Quick release pin to adjust height.

Stand will have 50mm of height adjustment.

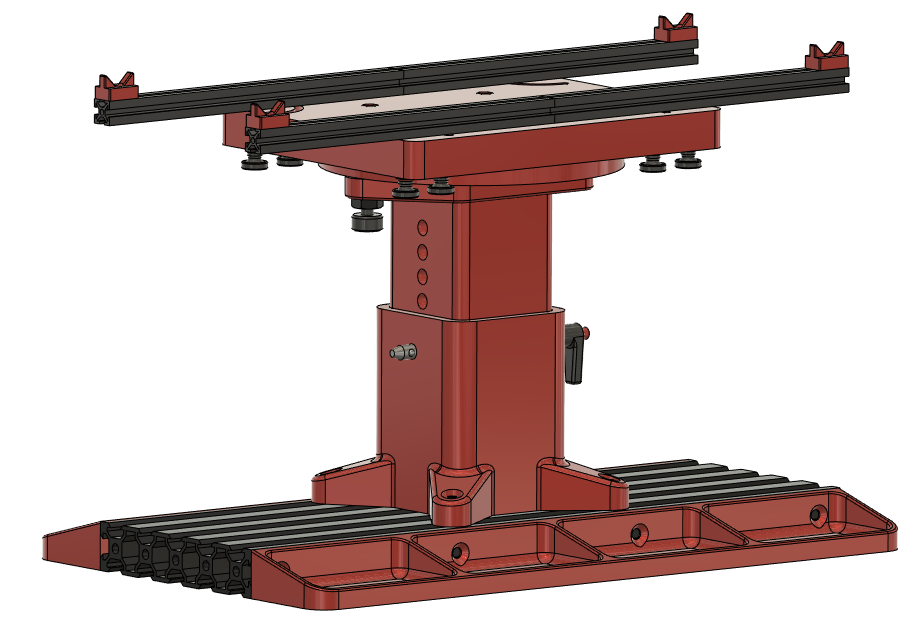

Lazy Susan bearing atop the riser to swivel the RC.

18° rotation locking. The highlighted spring plunger can be pulled down to unlock rotation. Pull down and twist the knob and that keeps it unlocked for free rotation. Pull down and release and it resumes lock function after rotating.

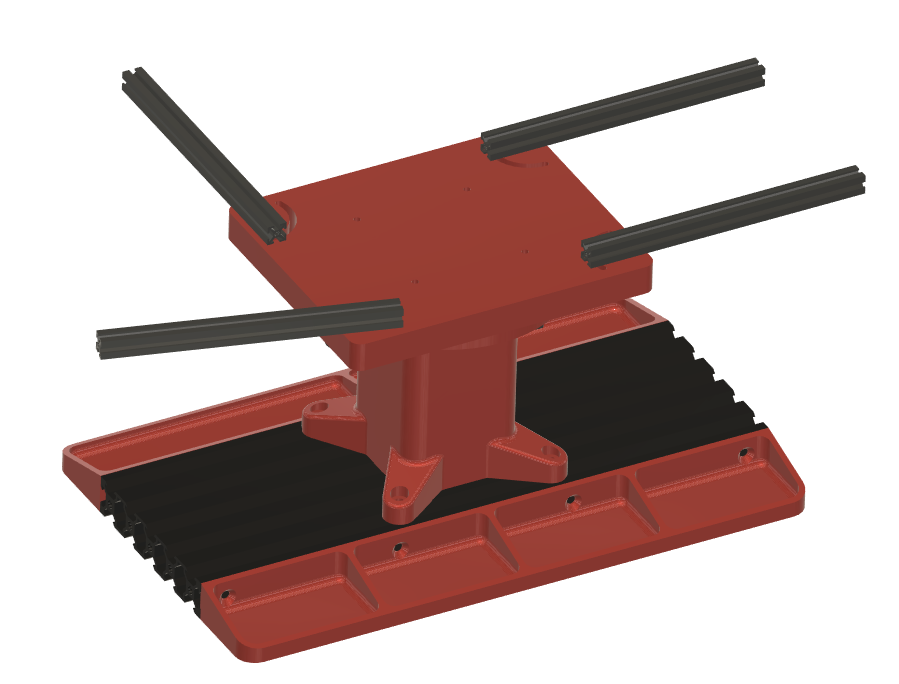

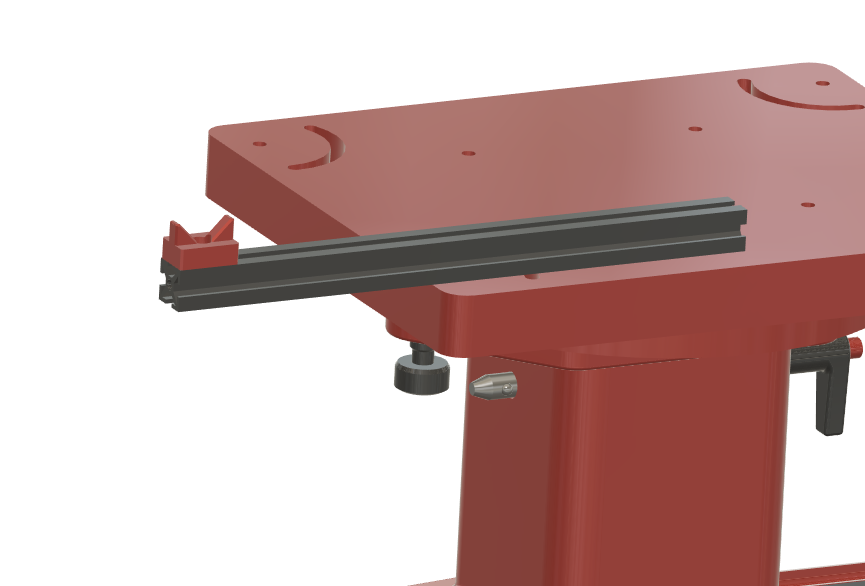

Arms atop the stand can slide in and out and rotate to reach any chassis or axle component, or they can be run across the stand, or removed completely.

Any number of attachments can be designed for the ends of the arms. These V-blocks will work for solid axle rigs.

Thumb screws under the table are used to lock the arms in place.

20mm x 100mm x 300mm aluminum extrusion for the base, with front and rear parts trays.

Quick release pin to adjust height.

Stand will have 50mm of height adjustment.

Lazy Susan bearing atop the riser to swivel the RC.

18° rotation locking. The highlighted spring plunger can be pulled down to unlock rotation. Pull down and twist the knob and that keeps it unlocked for free rotation. Pull down and release and it resumes lock function after rotating.

Arms atop the stand can slide in and out and rotate to reach any chassis or axle component, or they can be run across the stand, or removed completely.

Any number of attachments can be designed for the ends of the arms. These V-blocks will work for solid axle rigs.

Thumb screws under the table are used to lock the arms in place.

Last edited: