- Messages

- 5,962

- Reaction score

- 9,860

- Location

- Baltimore

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

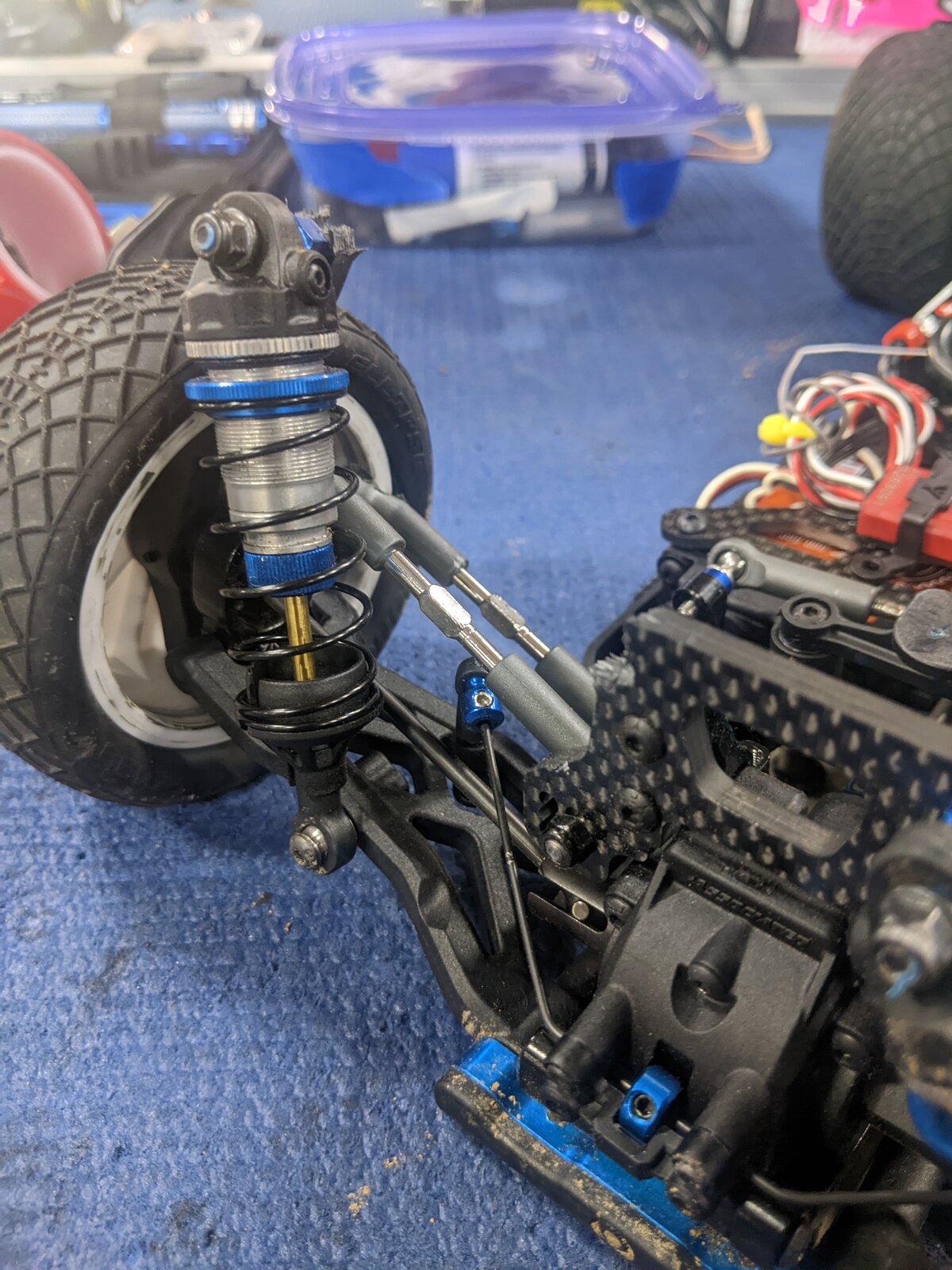

So I broke 2 carbon front shock towers on the B74. Is there anyway on how to make it stronger? On amain I saw a aluminum option part. Carbon fiber vs aluminum? I know aluminum can bend and might be heavier than carbon. I seen people using glue on the top of the shock tower and or using shock tower guards (most of the time 3d printed) I break the shock tower where the shock mounts to.

Try these...

Try these...