WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,989

- Reaction score

- 21,247

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

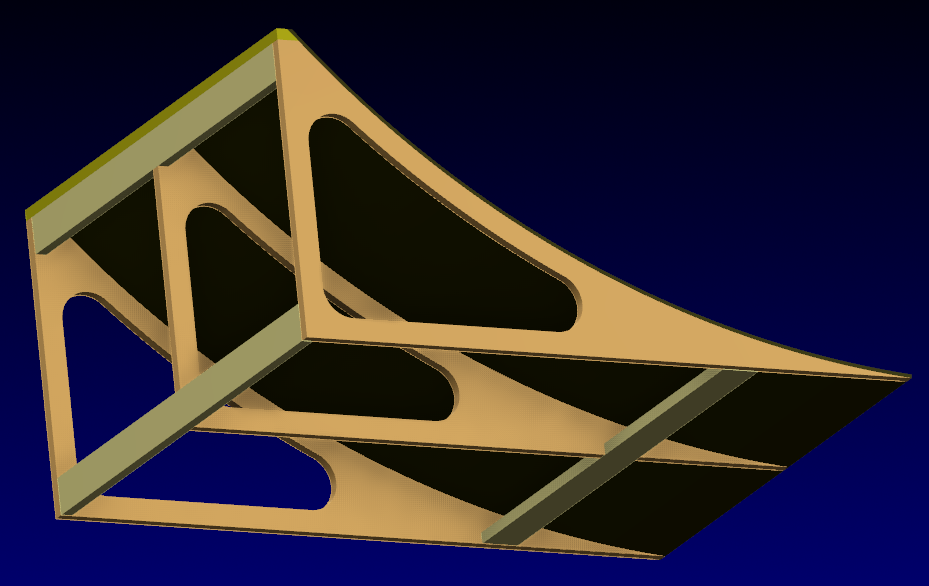

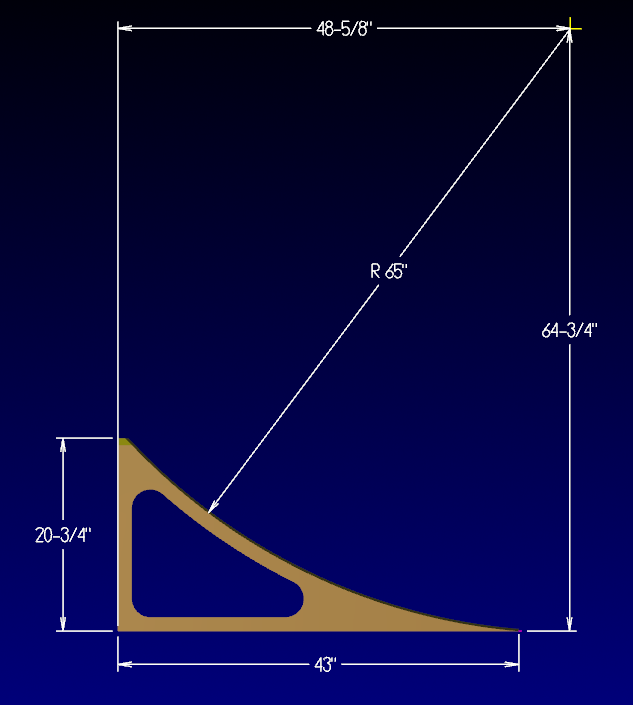

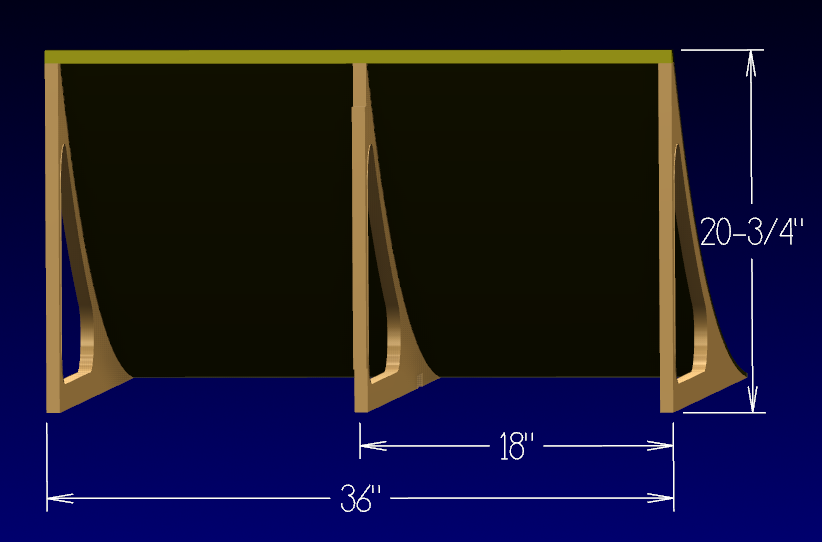

So I have been working with a local woodshop. This old guy is just loving the little projects I send him. The next one will be a ramp for the Kraton and our 1/10th stuff. Tell me if you think this looks ok.

The ramp board itself will either be 1/4" hardboard or hardwood plywood. We use 1/4" hardboard and blocks currently, so this will be a lot stronger. The goal is lightweight, but durable. The main supports will be cabinet grade (no voids) 3/4" plywood. The braces will be 1x3 pine lumber. Everything will have a finish to protect it from the weather, even though it won't see much weather.

The ramp board itself will either be 1/4" hardboard or hardwood plywood. We use 1/4" hardboard and blocks currently, so this will be a lot stronger. The goal is lightweight, but durable. The main supports will be cabinet grade (no voids) 3/4" plywood. The braces will be 1x3 pine lumber. Everything will have a finish to protect it from the weather, even though it won't see much weather.