I’m building a Turbo Scorpion for the sake of tinkering and perhaps some racing in a 13.5T stock buggy class (or vintage, if available).

This documentation will be far from step-by-step stuff but I’ll try to keep it comprehensible.

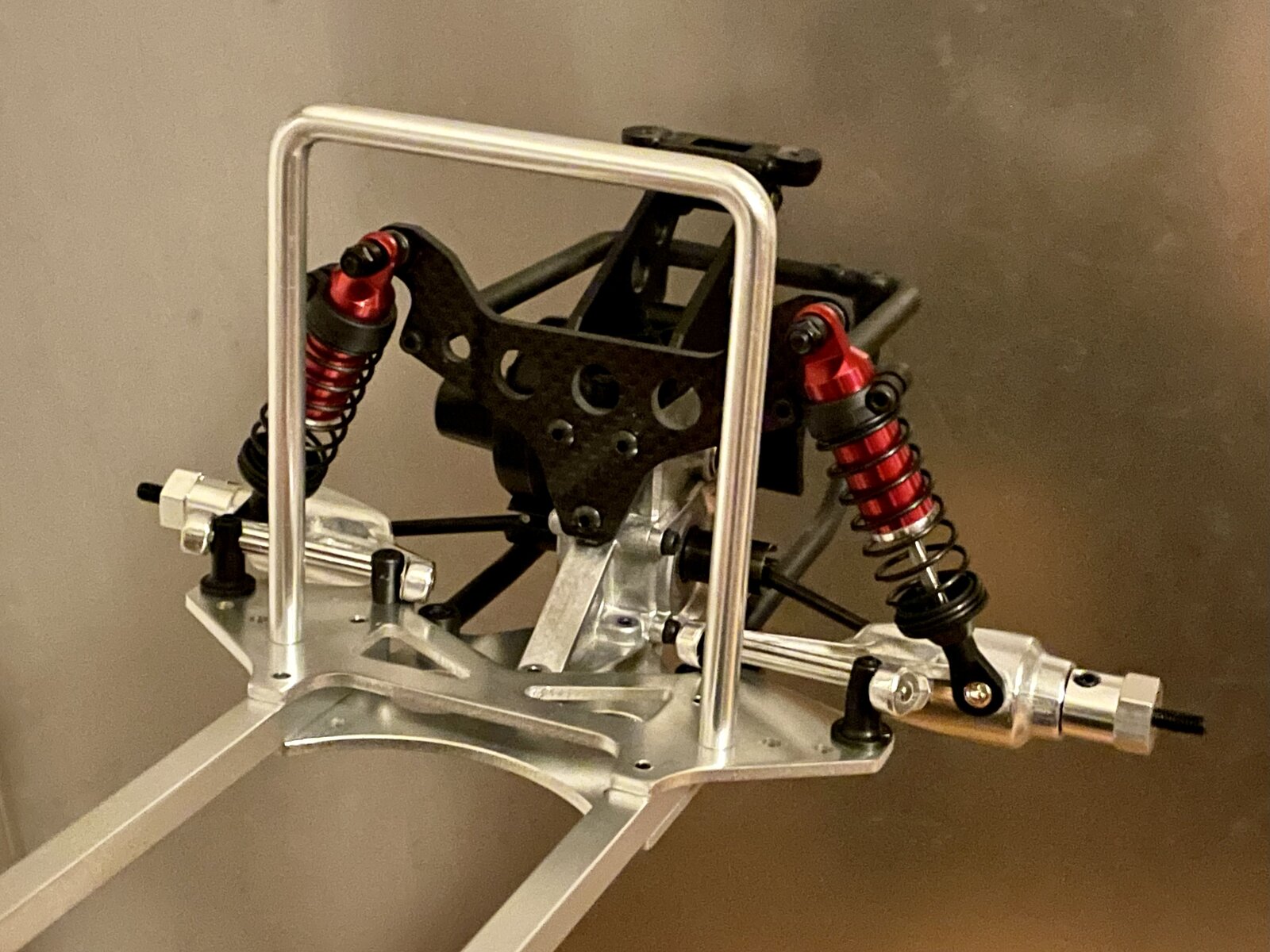

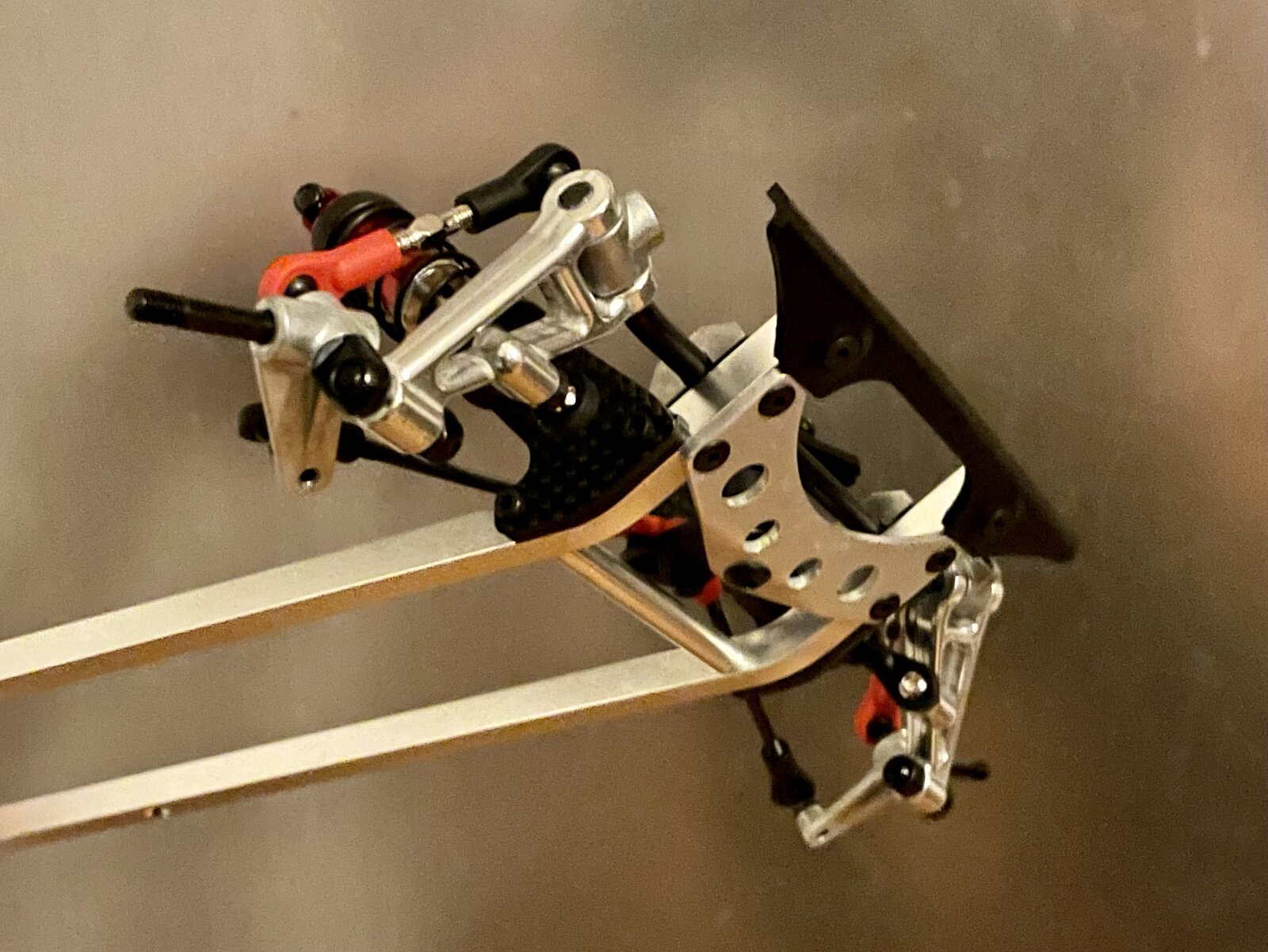

The local track is astroturf so I’ll have to do funny stuff with the setup to make it work a little better. Adjusting the suspension and steering is a jog for the brain.

As an aesthetic choice, I bought two sets of black shock plastics for the Optima to replace the stock red ones. The part trees the same, just a different color.

I didn’t realize the shock ends of the Turbo Scorpion don’t come off the shock plastics tree but they are a different part LA43. I put the black ball ends on the shocks and used the red ones in the front linkage. I’ll replace the ones on the control arms with black ones later.

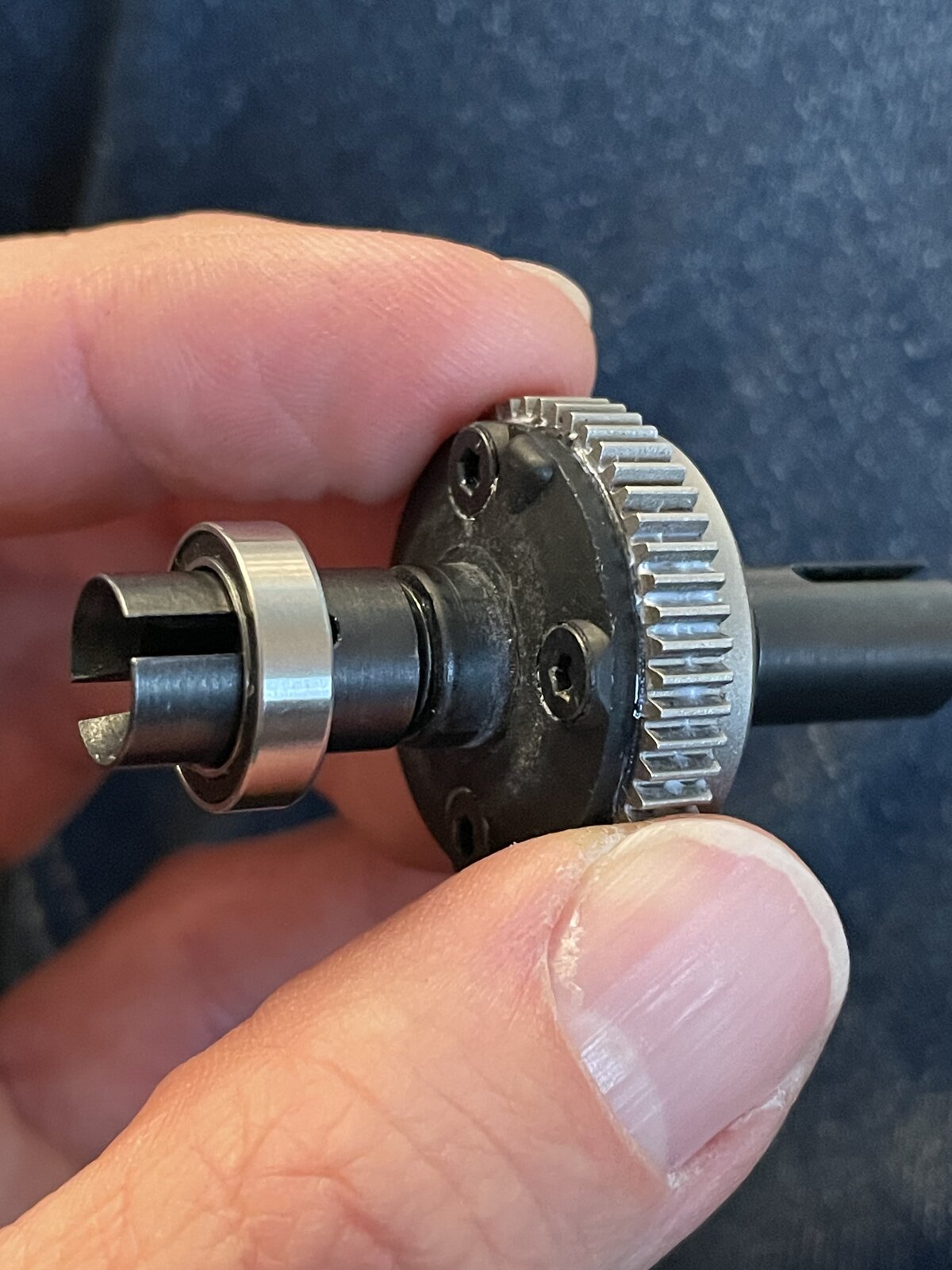

The plastic side of the diff had a tight fit to the bearing. I took off some material to make the bearing fit a little easier.

I also shimmed the outdrives and used 0.35 mm of shims on the metal side of the diff to remove sideways play and to get the diff exactly in the centerline of the chassis.

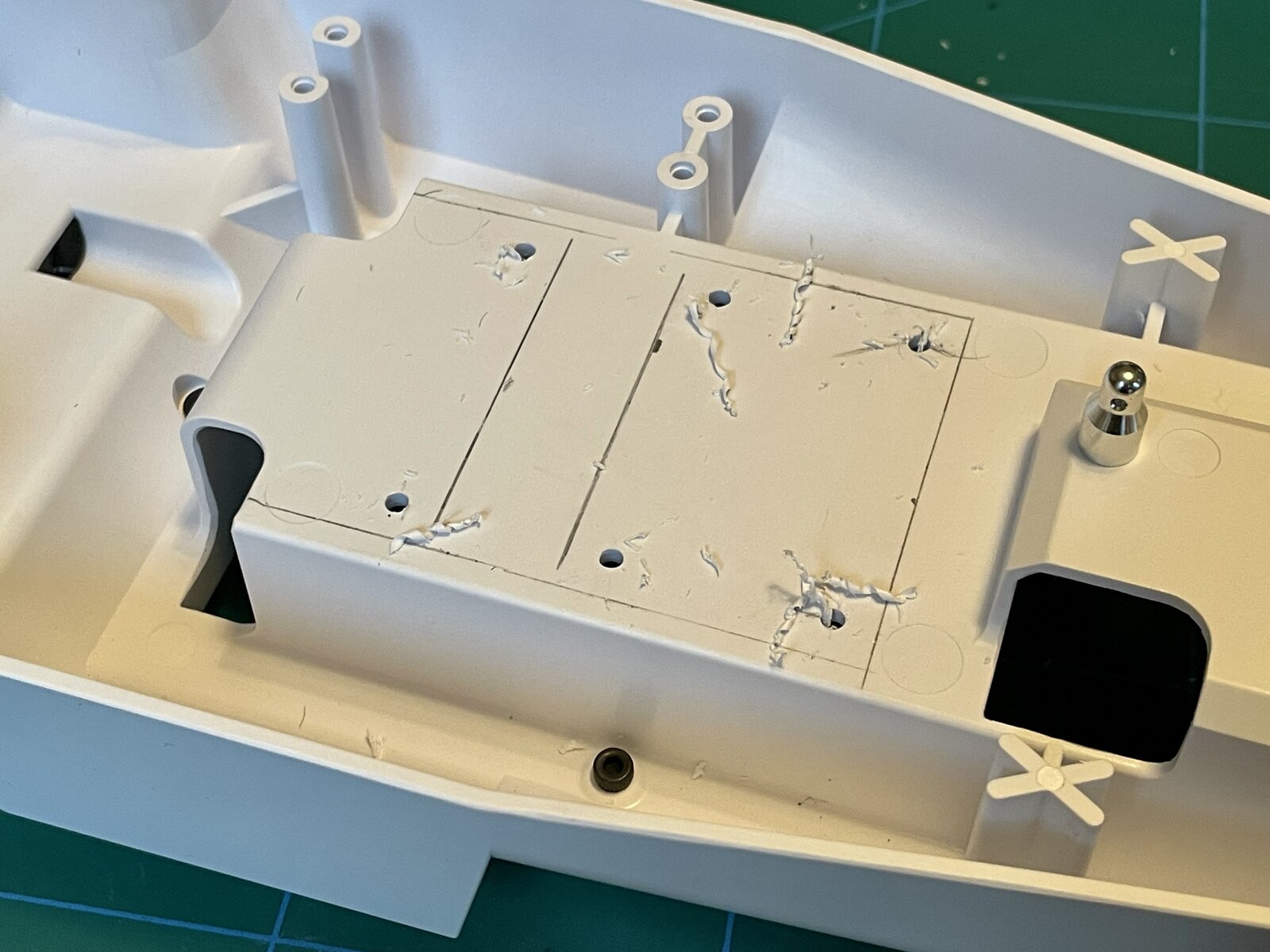

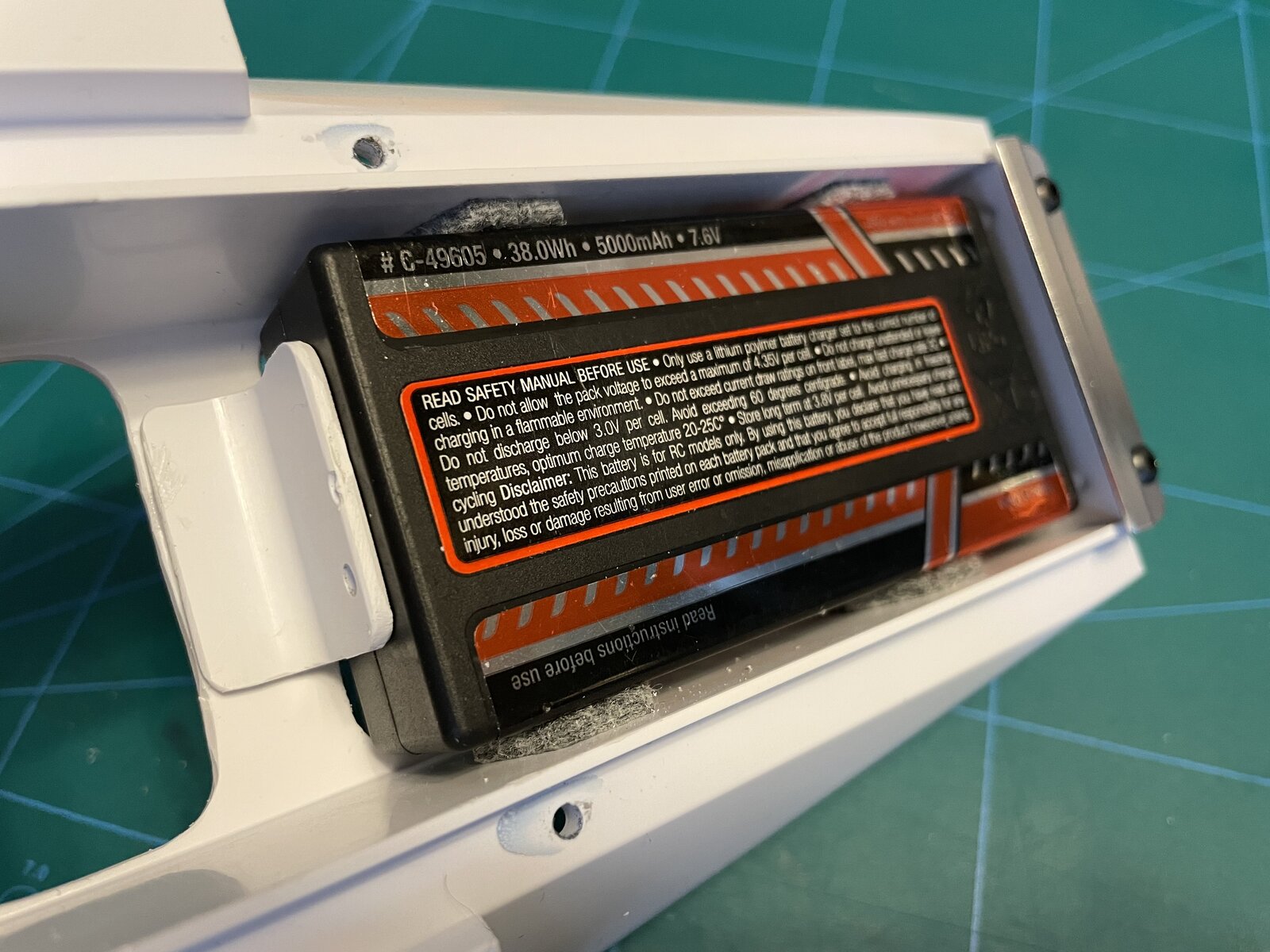

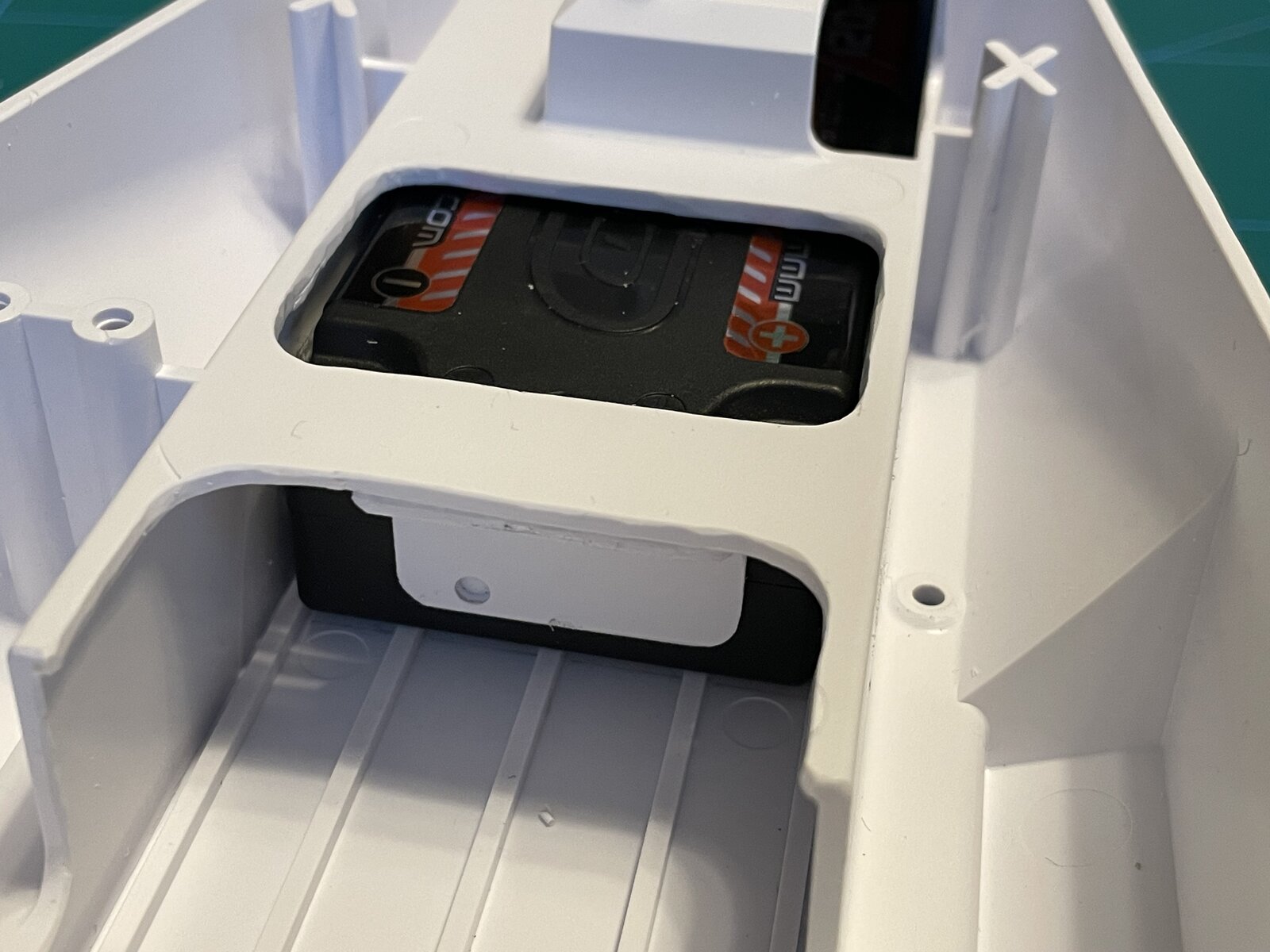

There will be lots of grip so I’m pushing the weight bias forward. I cut up the battery compartment so I can run a shorty pack all the way forward and bring the ESC also forward and lower. I transplanted one piece of the tub as a stopper for the shorty pack.

That’s all for now. I’ll add warm white LED lights as a finishing touch but there’s still a long way to go.

This documentation will be far from step-by-step stuff but I’ll try to keep it comprehensible.

The local track is astroturf so I’ll have to do funny stuff with the setup to make it work a little better. Adjusting the suspension and steering is a jog for the brain.

As an aesthetic choice, I bought two sets of black shock plastics for the Optima to replace the stock red ones. The part trees the same, just a different color.

I didn’t realize the shock ends of the Turbo Scorpion don’t come off the shock plastics tree but they are a different part LA43. I put the black ball ends on the shocks and used the red ones in the front linkage. I’ll replace the ones on the control arms with black ones later.

The plastic side of the diff had a tight fit to the bearing. I took off some material to make the bearing fit a little easier.

I also shimmed the outdrives and used 0.35 mm of shims on the metal side of the diff to remove sideways play and to get the diff exactly in the centerline of the chassis.

There will be lots of grip so I’m pushing the weight bias forward. I cut up the battery compartment so I can run a shorty pack all the way forward and bring the ESC also forward and lower. I transplanted one piece of the tub as a stopper for the shorty pack.

That’s all for now. I’ll add warm white LED lights as a finishing touch but there’s still a long way to go.