Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

More options

Who Replied?Put a piece of notebook paper in between the spur and pinion and push the motor against the paper and tighten down the screw that holds the motor still. Then pull out the paper.

+1Put a piece of notebook paper in between the spur and pinion and push the motor against the paper and tighten down the screw that holds the motor still. Then pull out the paper.

then to double check there should be a slight gap where you can rock the spur and hear a slight tapping sound as you go back and forth to confirm the small gap from the paper is still there...

Very important to use thread lock to secure the motor mount screws as well where I prefer gel based product:

Also a bit of loctite on the worm screw/set screw on the pinion gear.

When checking for slight tapping as you rock the spur gear, you should check all the way around. You may find a tight spot that is too tight…

When checking for slight tapping as you rock the spur gear, you should check all the way around. You may find a tight spot that is too tight…

+1Also a bit of loctite on the worm screw/set screw on the pinion gear.

When checking for slight tapping as you rock the spur gear, you should check all the way around. You may find a tight spot that is too tight…

WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,842

- Reaction score

- 20,947

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

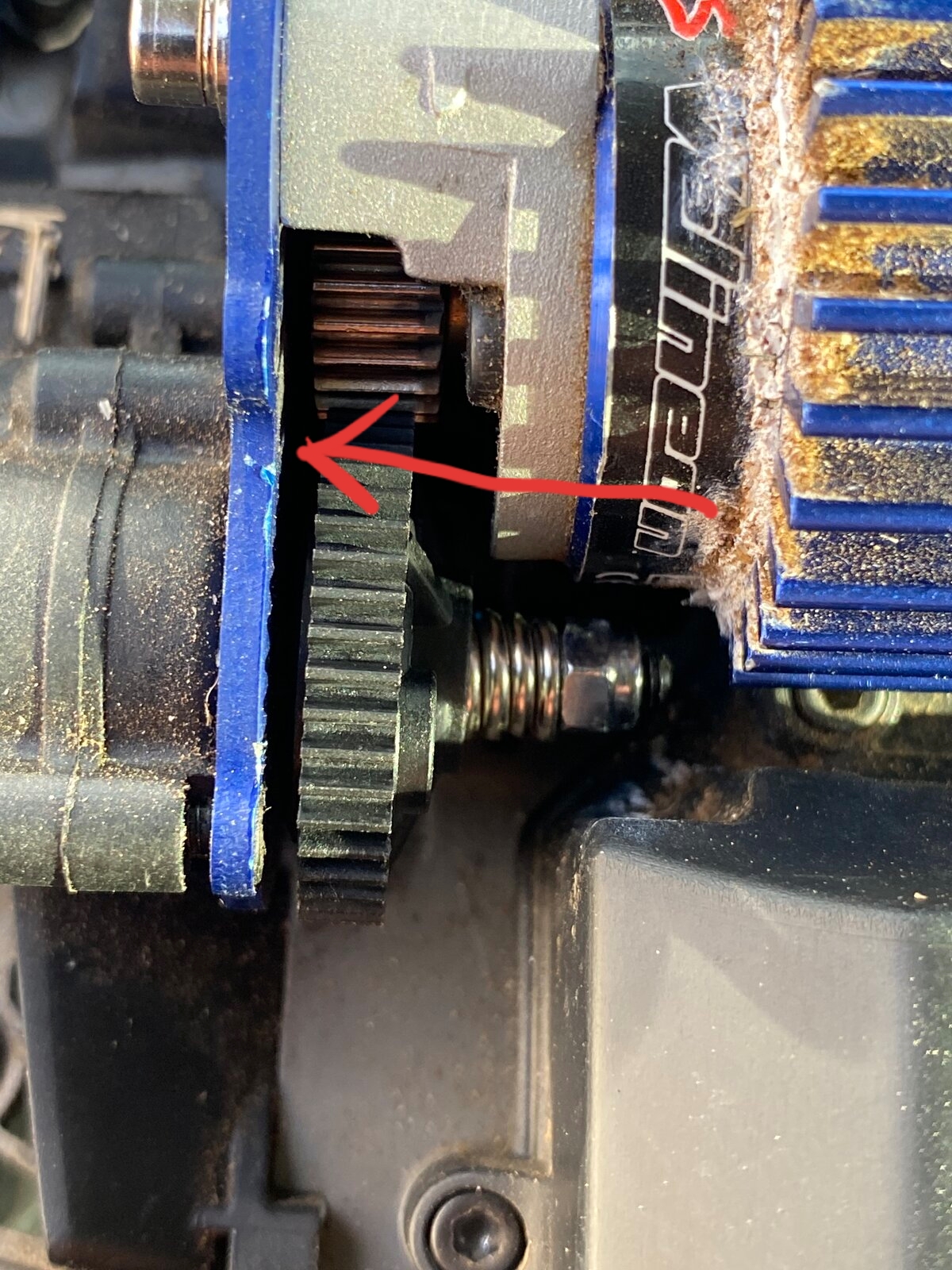

Before you set the mesh, you need to fix your motor plate, or replace it. It's bent. You can even see the gears are not parallel with each other. Unless it's just a weird camera angle. But it sure looks bent to me.

Last edited:

ohhhh I didn't catch that!Before you set the mesh, you need to fix your motor plate, or replace it. It's bent. You can even see the gears are not parallel with each other. Unless it's just a weird camera angle. But it sure looks bent to me.

View attachment 162271

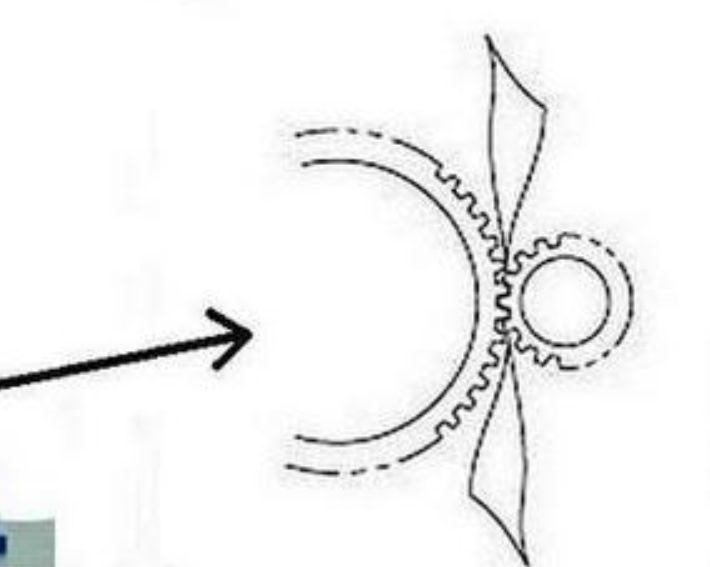

It is true that in order to achieve an optimal fit between the pinion and sprocket, it is sufficient to insert a small strip of paper (A4 copier type) between the two.

Once the screws are tightened securely, simply remove the paper and you are done.

However, from the photo, the pinion transmission gears appear not to be perfectly parallel and thus work poorly with fast wear during use.

Once the screws are tightened securely, simply remove the paper and you are done.

However, from the photo, the pinion transmission gears appear not to be perfectly parallel and thus work poorly with fast wear during use.

WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,842

- Reaction score

- 20,947

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

After getting the motor plate checked out and replaced if needed...

Remove the spur gear assembly. Check the input shaft the spur is on by rolling it on a flat surface and make sure it's not bent. If it is, replace it. You might not even be able to see it if it is bent, but you can check that a little better after assembly.

Reassemble and do the paper method mentioned above to set the mesh. After removing the paper, rotate the gears one full revolution of the spur and check the backlash every 90° of rotation. If the gears are running concentric, the backlash should be the same all the way around. There should be just a very slight, barely noticeable rocking of the spur gear before the pinion tries to rotate, at all 4 spots around the spur. If it gets tighter or looser, it is likely your spur gear has runout, possibly caused by a bent input shaft.

I would be curious to know which Traxxas kit this is to get a better look at that motor plate design. I suspect it's another one of their design failures

Remove the spur gear assembly. Check the input shaft the spur is on by rolling it on a flat surface and make sure it's not bent. If it is, replace it. You might not even be able to see it if it is bent, but you can check that a little better after assembly.

Reassemble and do the paper method mentioned above to set the mesh. After removing the paper, rotate the gears one full revolution of the spur and check the backlash every 90° of rotation. If the gears are running concentric, the backlash should be the same all the way around. There should be just a very slight, barely noticeable rocking of the spur gear before the pinion tries to rotate, at all 4 spots around the spur. If it gets tighter or looser, it is likely your spur gear has runout, possibly caused by a bent input shaft.

I would be curious to know which Traxxas kit this is to get a better look at that motor plate design. I suspect it's another one of their design failures