Hey everybody,

This is my first RC project and I don't know much about RC. I'm using a push lawnmower with a 6hp Briggs and Stratton engine to build a winch. I talked about this idea in my intro and got some good ideas. The whole plan is a little more refined now, but I still have questions about this RC stuff.

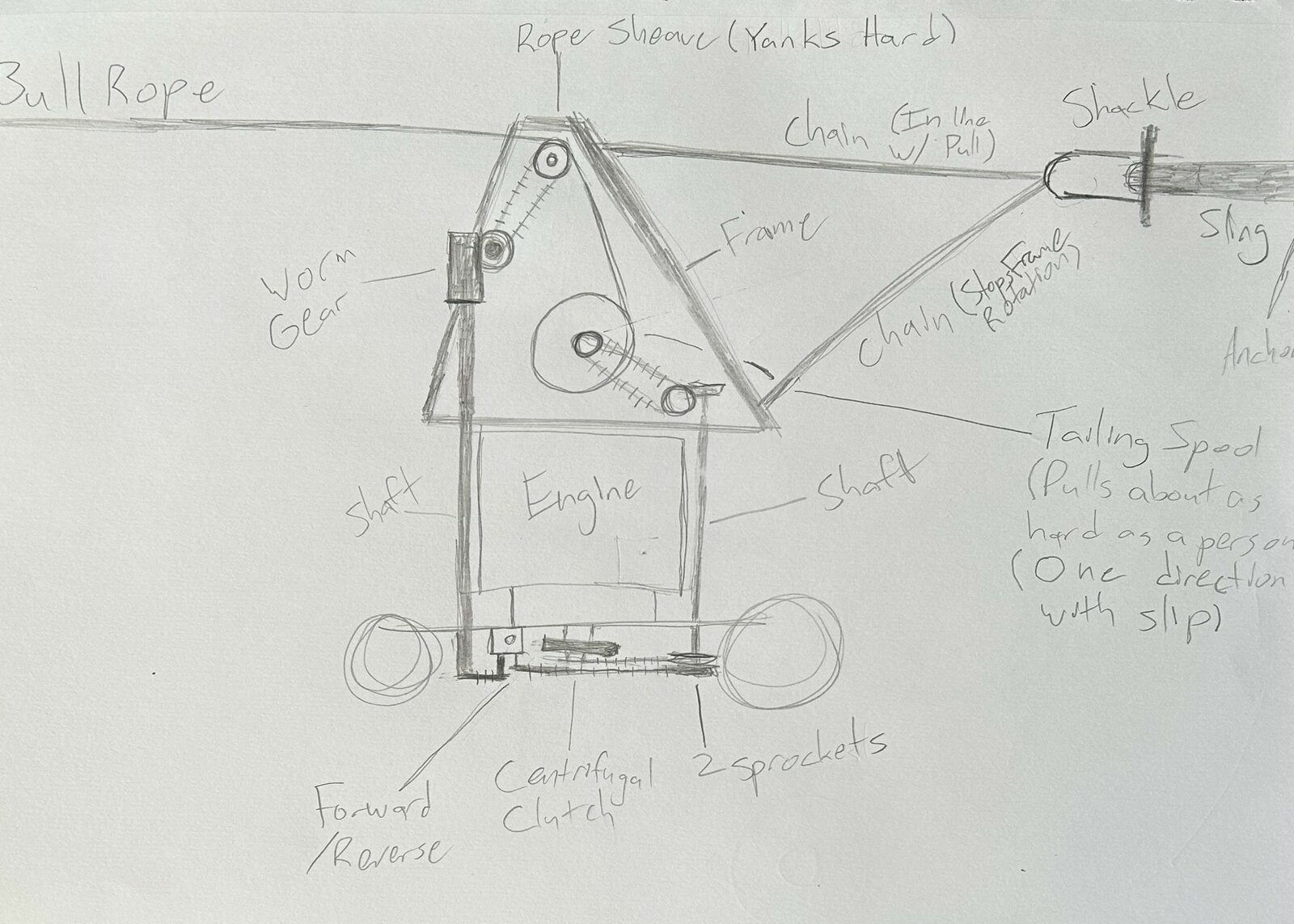

I drew the wheels facing the wrong way, but that's the basic plan. The winch will be pulling in line about 90 degrees from the lawnmower wheels. There are a few things I didn't draw in, I'll get to that when I get to the final dimensions. There's a rope sheave being turned by a worm gear that's doing all the pulling, and then there's a spool/reel with a slip clutch to pull the tail. The worm gear has a forward/n/reverse gearbox for a go-kart. It's all run off a centrifugal clutch, so every time I hit the gas the reel pulls the tail with whatever torque I set it to slip at while the worm gear turns the sheave whichever direction I tell it to.

https://www.amazon.com/dp/B07DPK9Q9X?psc=1&ref=ppx_yo2ov_dt_b_product_details

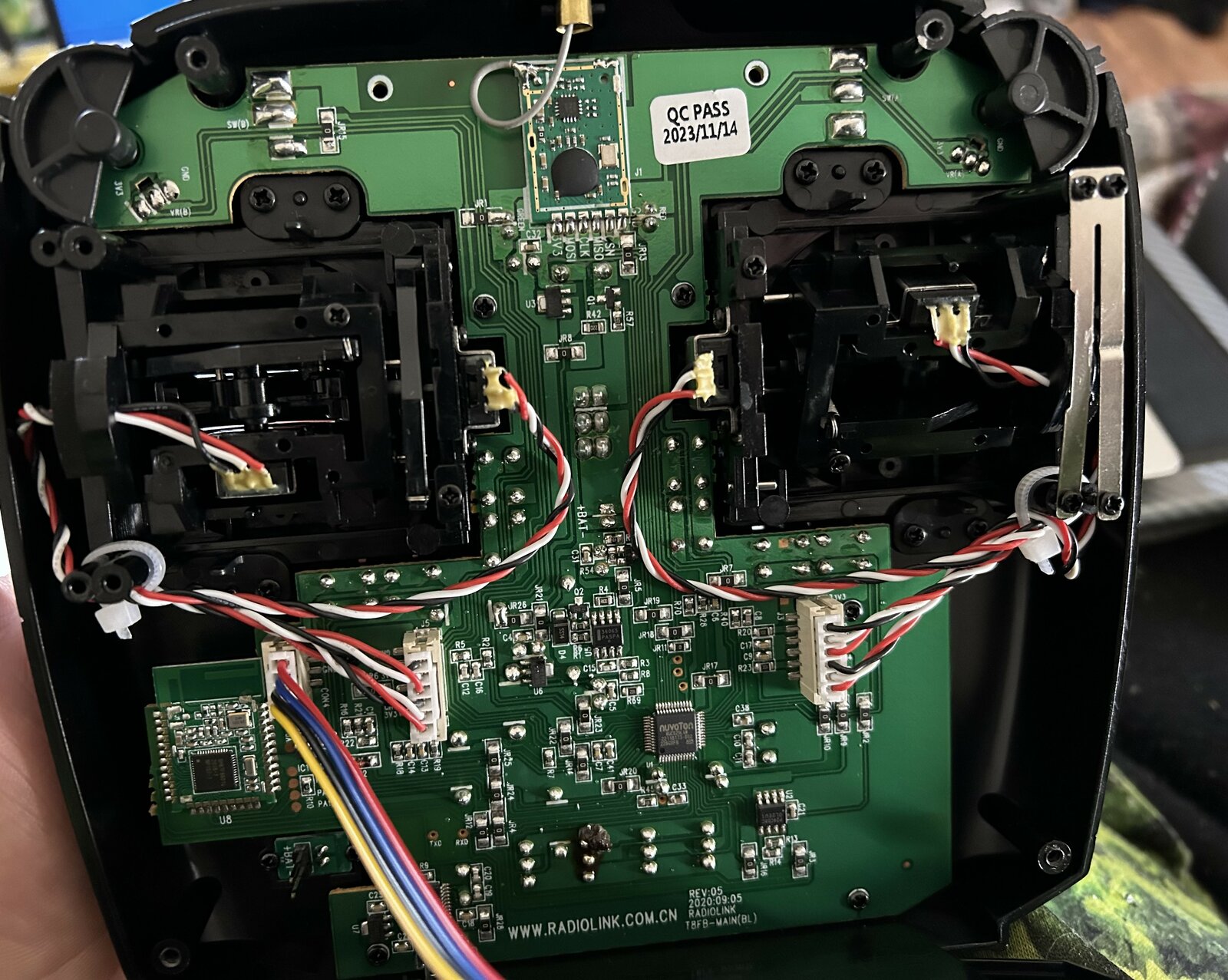

This is the Radiolink T8FB 8 channel remote and receiver I chose.

Once I figure out the whole RC setup and build the machine, I might want to rebuild the controller so it's more machine like. How hard would it be to change out the potentiometers for switches and buttons?

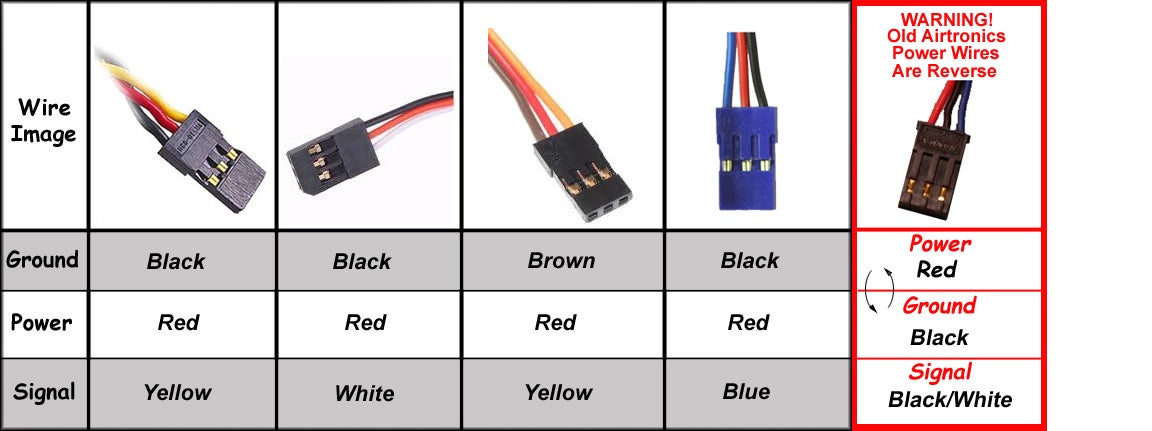

Here's the thing I'm having trouble understanding. If I have an 18v 12ah battery, like the Milwaukee M18 battery in the picture that's at every job site I've been to in the last few years and that I already own a few of, can I run the 6v servos off them?

I'm not an electromagician but I can solder wires.

Here's a list of things I want to control with electronics:

Throttle - servo - throttle lever/stick

Forward/Neutral/Reverse - servo - 3 position switch

Ignition/ Kill Switch - servo - 2 position switch

Electric start - I have an old drill that I think I can work into the recoil - momentary switch

Horn - maybe a motorcycle electromagnetic horn, just needs 12v on and off - momentary switch

Do I need to get some kind of arduino or something like that to make all that stuff work on the receiving end, or does that all just plug into the receiver and work off the signal from the remote?

What kind of stuff do I need to do to protect the circuitry on the winch? Does it need a fuse box? Diodes? Are cordless tool batteries even a good choice, or do I need to look into something else? it would be super convenient to run it off the M18 batteries.

I think I kind of get how this RC stuff is set up but I don't fully understand where it all plugs in and how it all works together. Can someone please explain it to me or else show me the resources so I can understand it?

I'll continue to update this thread as I build the winch for anyone interested.

This is my first RC project and I don't know much about RC. I'm using a push lawnmower with a 6hp Briggs and Stratton engine to build a winch. I talked about this idea in my intro and got some good ideas. The whole plan is a little more refined now, but I still have questions about this RC stuff.

I drew the wheels facing the wrong way, but that's the basic plan. The winch will be pulling in line about 90 degrees from the lawnmower wheels. There are a few things I didn't draw in, I'll get to that when I get to the final dimensions. There's a rope sheave being turned by a worm gear that's doing all the pulling, and then there's a spool/reel with a slip clutch to pull the tail. The worm gear has a forward/n/reverse gearbox for a go-kart. It's all run off a centrifugal clutch, so every time I hit the gas the reel pulls the tail with whatever torque I set it to slip at while the worm gear turns the sheave whichever direction I tell it to.

https://www.amazon.com/dp/B07DPK9Q9X?psc=1&ref=ppx_yo2ov_dt_b_product_details

This is the Radiolink T8FB 8 channel remote and receiver I chose.

Once I figure out the whole RC setup and build the machine, I might want to rebuild the controller so it's more machine like. How hard would it be to change out the potentiometers for switches and buttons?

Here's the thing I'm having trouble understanding. If I have an 18v 12ah battery, like the Milwaukee M18 battery in the picture that's at every job site I've been to in the last few years and that I already own a few of, can I run the 6v servos off them?

I'm not an electromagician but I can solder wires.

Here's a list of things I want to control with electronics:

Throttle - servo - throttle lever/stick

Forward/Neutral/Reverse - servo - 3 position switch

Ignition/ Kill Switch - servo - 2 position switch

Electric start - I have an old drill that I think I can work into the recoil - momentary switch

Horn - maybe a motorcycle electromagnetic horn, just needs 12v on and off - momentary switch

Do I need to get some kind of arduino or something like that to make all that stuff work on the receiving end, or does that all just plug into the receiver and work off the signal from the remote?

What kind of stuff do I need to do to protect the circuitry on the winch? Does it need a fuse box? Diodes? Are cordless tool batteries even a good choice, or do I need to look into something else? it would be super convenient to run it off the M18 batteries.

I think I kind of get how this RC stuff is set up but I don't fully understand where it all plugs in and how it all works together. Can someone please explain it to me or else show me the resources so I can understand it?

I'll continue to update this thread as I build the winch for anyone interested.