I know a lot of us have given up on gluing tires since it's almost impossible to remove them without ruining the rim.

Bead locks solve the problem of swapping treads for different terrain or conditions but are usually stubborn and time consuming. You start one screw and the tire bead comes out on the other side. You try to hold the 2 halves of the rim together while trying to line up a nut with the screw and turn the hex driver at the same time. You're one hand short and the process gets very frustrating.

In this tutorial I'll be using the most complex rims I've ever used, so you'll see how easy it should be with a 5 lug pattern that most of the wheels have.

Here's a Humm Vee 2.2 alloy bead lock wheel from RC4WD. This is what I'll be working with.

You can see how flat the side wall appears on the tire on the right and how it rounds out when fully mounted

Here's the wheel out of the box and after painting. It comes assembled and you're already looking at 5 minutes

just taking it apart. There are 20 screws on each of these wheels and the manufacturer says it will be 45 minutes

to an hour to mount the tire to each one. We're about to knock it down to 20 non frustrating minutes.

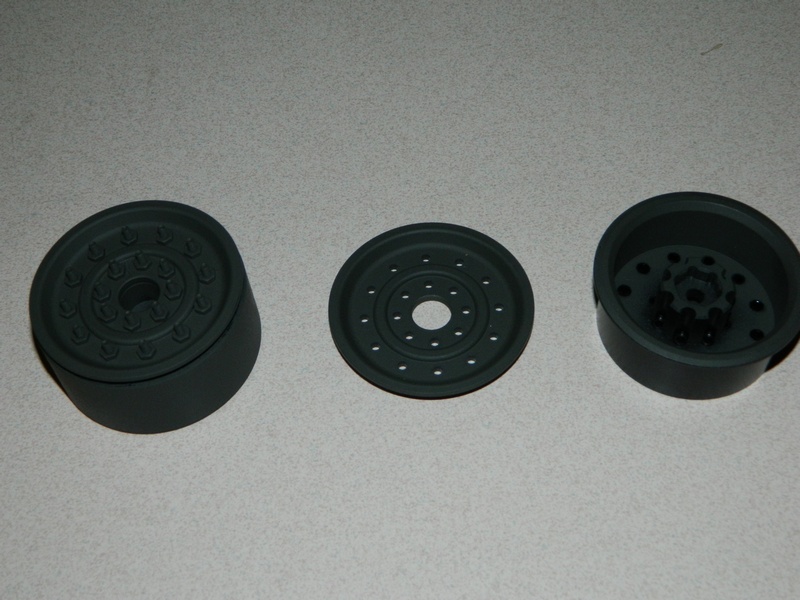

Here's the first one, torn down. Inner ring, front of the hub and the rear of the hub. After this tear down it gets a

quick shot of paint on the front to cover the area where the nuts were during the initial painting.

Painted, dried and ready to go.

On the left is a new tire with the foam rubber insert and on the right the inner ring has been added.

On these rims the holes are not always a direct line-up any way you put them, so you must make sure

you can see through ALL the holes before you start putting in screws.

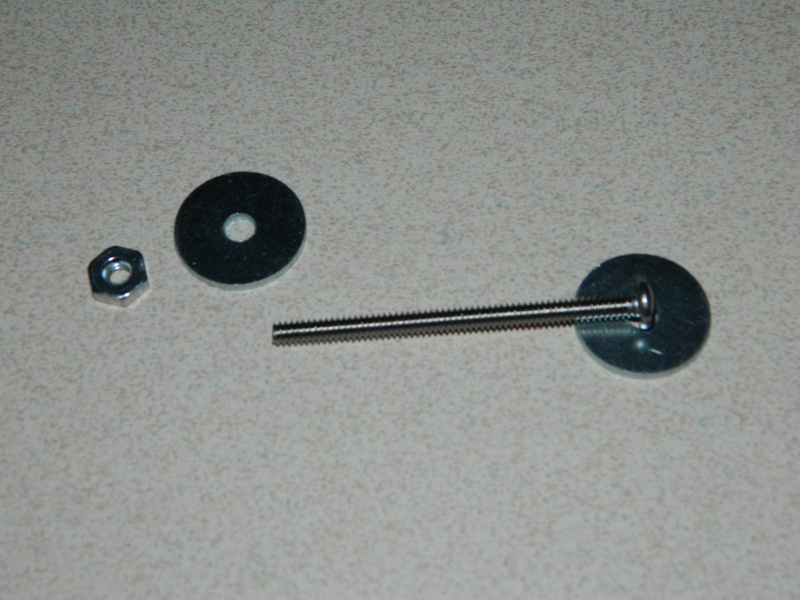

Here's the amazing tool I'm selling for $39.95. Act now and shipping is free.

You can also get it in a hardware store for under a buck. The screw needs to be slender enough to fit through

the axle opening in the rear of the hub. The washers will come into play in a second.

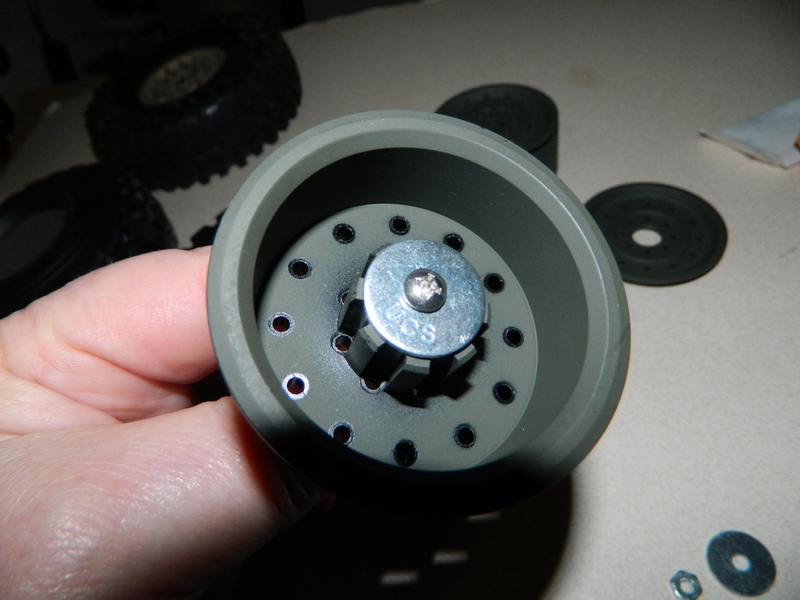

Put it through the washer and slide it in from the rear as shown here...

Drop the tire on, put the front of the hub on, drop on the washer and spin the nut down with your fingers. No need to screw it tight, just enough to squeeze the two halves against the tire and line it up evenly with the center ring.

When the tire is perfectly centered on the front and the rear you can tighten it down a little more but there's no reason to go much past snug. You just want all the parts centered and secured to begin adding the lugs.

If the tire is not perfectly centered, as shown by the slight gap on top, just loosen the "Special Tool" and realign it.

Now I've triangulated 3 screws and snugged them down. NOT tightened, just snug. The "Tool" in the middle will loosen when the 3 nuts are snugged in place.

Here the tool is removed and all parts of the assembly are in place and ready for all the screws. If you're doing a 5 lug wheel you can put all 5 in at once before removing the "Special" tool....(Patent pending)

Next I did the inner ring. Again just snugging them and not tightening.

Finally I did the outer ring, and once they were all in place I tightened each one a little at a

time in a cross pattern like torquing down a head. About 3 times around till they were tight, then tightened the inside row.

There you have it. One down and 3 more to go.

Bead locks solve the problem of swapping treads for different terrain or conditions but are usually stubborn and time consuming. You start one screw and the tire bead comes out on the other side. You try to hold the 2 halves of the rim together while trying to line up a nut with the screw and turn the hex driver at the same time. You're one hand short and the process gets very frustrating.

In this tutorial I'll be using the most complex rims I've ever used, so you'll see how easy it should be with a 5 lug pattern that most of the wheels have.

Here's a Humm Vee 2.2 alloy bead lock wheel from RC4WD. This is what I'll be working with.

You can see how flat the side wall appears on the tire on the right and how it rounds out when fully mounted

Here's the wheel out of the box and after painting. It comes assembled and you're already looking at 5 minutes

just taking it apart. There are 20 screws on each of these wheels and the manufacturer says it will be 45 minutes

to an hour to mount the tire to each one. We're about to knock it down to 20 non frustrating minutes.

Here's the first one, torn down. Inner ring, front of the hub and the rear of the hub. After this tear down it gets a

quick shot of paint on the front to cover the area where the nuts were during the initial painting.

Painted, dried and ready to go.

On the left is a new tire with the foam rubber insert and on the right the inner ring has been added.

On these rims the holes are not always a direct line-up any way you put them, so you must make sure

you can see through ALL the holes before you start putting in screws.

Here's the amazing tool I'm selling for $39.95. Act now and shipping is free.

You can also get it in a hardware store for under a buck. The screw needs to be slender enough to fit through

the axle opening in the rear of the hub. The washers will come into play in a second.

Put it through the washer and slide it in from the rear as shown here...

Drop the tire on, put the front of the hub on, drop on the washer and spin the nut down with your fingers. No need to screw it tight, just enough to squeeze the two halves against the tire and line it up evenly with the center ring.

When the tire is perfectly centered on the front and the rear you can tighten it down a little more but there's no reason to go much past snug. You just want all the parts centered and secured to begin adding the lugs.

If the tire is not perfectly centered, as shown by the slight gap on top, just loosen the "Special Tool" and realign it.

Now I've triangulated 3 screws and snugged them down. NOT tightened, just snug. The "Tool" in the middle will loosen when the 3 nuts are snugged in place.

Here the tool is removed and all parts of the assembly are in place and ready for all the screws. If you're doing a 5 lug wheel you can put all 5 in at once before removing the "Special" tool....(Patent pending)

Next I did the inner ring. Again just snugging them and not tightening.

Finally I did the outer ring, and once they were all in place I tightened each one a little at a

time in a cross pattern like torquing down a head. About 3 times around till they were tight, then tightened the inside row.

There you have it. One down and 3 more to go.

Last edited: