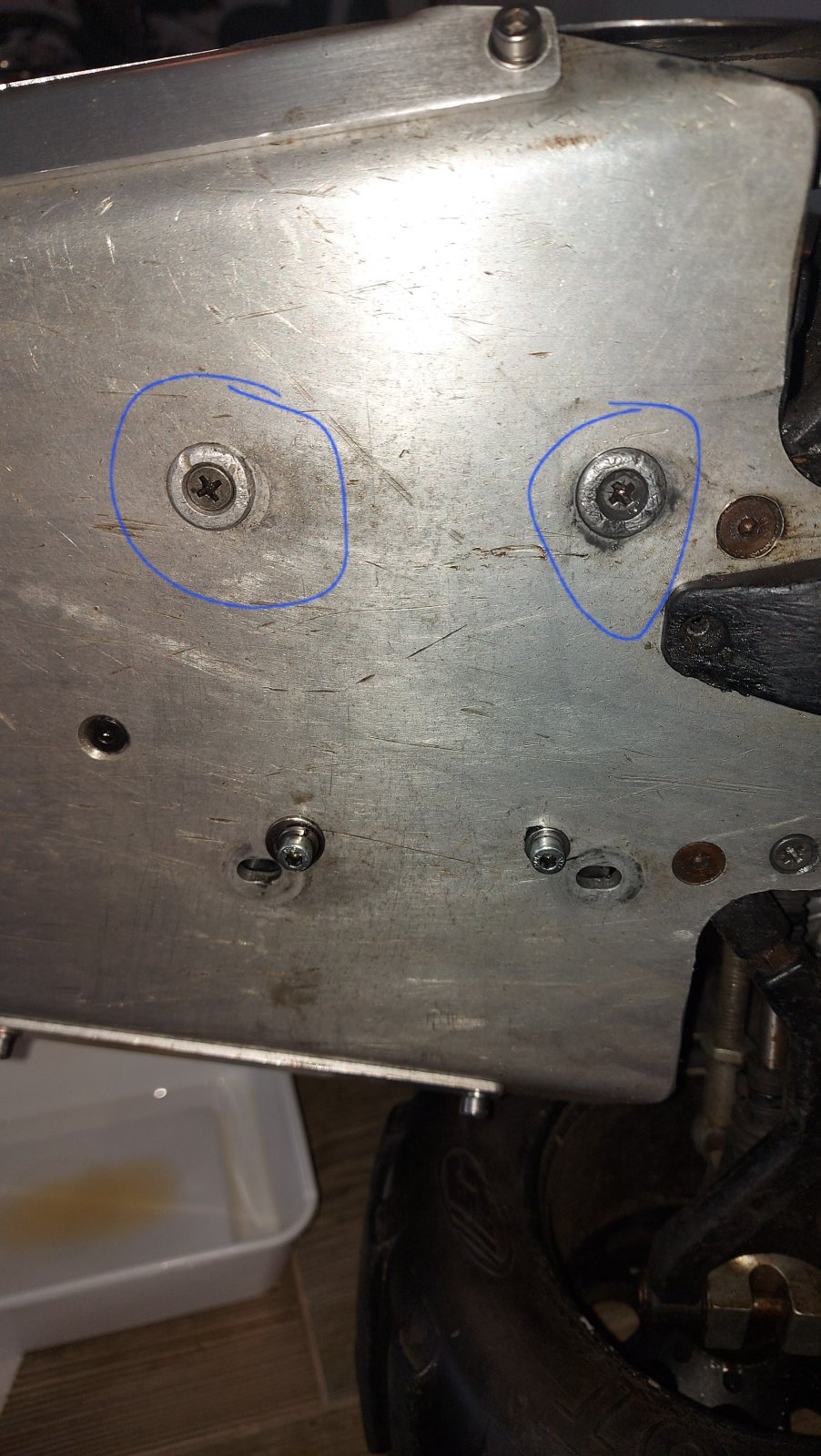

Hello, these two screws keep falling out

they go in plastic, so there is no point in using threadlock. Every time i try to drive my FG monstertruck with zen 26cc, i end up with those screws almost falling out! Really annoying me now. I just stripped the place where the right screw goes in. Out of ideas. Every time i screwed those screws in, i did it really tight.

they go in plastic, so there is no point in using threadlock. Every time i try to drive my FG monstertruck with zen 26cc, i end up with those screws almost falling out! Really annoying me now. I just stripped the place where the right screw goes in. Out of ideas. Every time i screwed those screws in, i did it really tight.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

More options

Who Replied?WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,940

- Reaction score

- 21,157

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

You could try plastic weld (or acetone, nail polish remover, etc). Put a drop of it on the plastic part and see if it melts that plastic. If it does, find some other plastic that it melts. Make a slurry by melting some plastic in the acetone, and use a toothpic to somewhat fill in the hole with the plastic slurry. That will make it like a new hole.

- Thread starter

- #4

Does loctite actually work in plastic??Red loctite, let sit overnight?

WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,940

- Reaction score

- 21,157

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

Loctite is liquid plastic basically. It may work. I've never tried it, but you could try putting some in the hole and letting it setup. Do not put it on the screw and let it setup. It will just push the plastic around in the hole as the screw goes in. I would opt for the plastic weld slurry myself.Does loctite actually work in plastic??

- Thread starter

- #6

Thanks!Loctite is liquid plastic basically. It may work. I've never tried it, but you could try putting some in the hole and letting it setup. Do not put it on the screw and let it setup. It will just push the plastic around in the hole as the screw goes in. I would opt for the plastic weld slurry myself.

A few options.

There is thread lock specifically for plastic. Although, I've never used it and don't know how reusable the plastic is afterwards.

Another option is to see if you can get a larger screw in there. It makes a huge difference on marginal sized holes.

The last thing I can think of is put a drop of super glue or silicon RTV on the edge of the screw and the chassis. It "might" lock it in place and keep it from turning. I say might because it depends on a lot of things, but it's inexpensive, easy to do and reversible.

There is thread lock specifically for plastic. Although, I've never used it and don't know how reusable the plastic is afterwards.

This one is super glue based

This one looks like it's more for mending.

Another option is to see if you can get a larger screw in there. It makes a huge difference on marginal sized holes.

The last thing I can think of is put a drop of super glue or silicon RTV on the edge of the screw and the chassis. It "might" lock it in place and keep it from turning. I say might because it depends on a lot of things, but it's inexpensive, easy to do and reversible.

- Thread starter

- #8

I just did it, but I think it changed the gear mesh a bit. Do you think I should move the engine a bit more towards the diff? So the smaller gear touches more of the diff gearYou could try plastic weld (or acetone, nail polish remover, etc). Put a drop of it on the plastic part and see if it melts that plastic. If it does, find some other plastic that it melts. Make a slurry by melting some plastic in the acetone, and use a toothpic to somewhat fill in the hole with the plastic slurry. That will make it like a new hole.

It's hard to see how much engagement there is from the picture. But you want a little bit of play and it should not be "tight". The larger the gear pitch the more lash you can have.

For 48P gears, it's pretty tight and you should be able to get a piece of paper between the gears. For Mod 1 it's a bit looser and just a bit of play so you can hear a click when you roll it back and forth, maybe 2 pieces of a paper.

For 48P gears, it's pretty tight and you should be able to get a piece of paper between the gears. For Mod 1 it's a bit looser and just a bit of play so you can hear a click when you roll it back and forth, maybe 2 pieces of a paper.

WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,940

- Reaction score

- 21,157

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

Yeah, slide the motor over and pinch a sheet of notebook paper between there, and tighten the motor screws.I just did it, but I think it changed the gear mesh a bit. Do you think I should move the engine a bit more towards the diff? So the smaller gear touches more of the diff gearView attachment 165076

- Thread starter

- #11

Thanks, I moved the gear more towards the big diff gear. It started making this noise now:Yeah, slide the motor over and pinch a sheet of notebook paper between there, and tighten the motor screws.

https://www.mediafire.com/file/y2i33xrel8lcfir/20230507_162647.mp4/file

Is this fine or is it too tight?

Btw, I screwed the screw in yesterday after drowning its hole in loctite, and today i had to scrape off the loctite which became solid in the engine mounting place

Thanks, I moved the gear more towards the big diff gear. It started making this noise now:

https://www.mediafire.com/file/y2i33xrel8lcfir/20230507_162647.mp4/file

Is this fine or is it too tight?

Btw, I screwed the screw in yesterday after drowning its hole in loctite, and today i had to scrape off the loctite which became solid in the engine mounting place. The rest did work out nicely tho

Sorry, it's hard to see the mesh on the video but it looks maybe a bit tight? There should be a tiny amount of play in the mesh. Just wiggle it back and fourth.

Notice at around 2:30 he moves the gears and you can see the tiniest movement. Just a bit of clicking sound. You will need to move the spur gear back and fourth, not the wheels. If you can't reach it use a small driver or pointy thing to get in there.

Here is another video with close ups of the motion.

cbaker65

RCTalk VIP

Hello, these two screws keep falling outView attachment 164953they go in plastic, so there is no point in using threadlock. Every time i try to drive my FG monstertruck with zen 26cc, i end up with those screws almost falling out! Really annoying me now. I just stripped the place where the right screw goes in. Out of ideas. Every time i screwed those screws in, i did it really tight.

Get different screws an use lock washers!

Sometimes I use old weedeater screws that have those built on washers!..