crzy-svg-usr

RCTalk Qualifier

- Messages

- 170

- Reaction score

- 0

- RC Driving Style

Ok in this thread I will explain how I vacuum formed the hpi savage radio box to be a bigger piece that is also clear. You can mod this concept to allow for bigger pieces, different thick nesses, and different products.

Materials needed:

1.Angle Iron

2.Big office Clips

3.Plaster of Paris

4.Big aluminum tray

5.Misc wood scraps

6.Caulk

7.Different sandpapers, ranging from fine to very fine

8.Misc tools to build everything

9.Oven or other heat source (toaster oven)

The first couple of things that you will need to build are the frame and box. The frame has to be slightly bigger then the box or else the whole process won’t work. the frame is what holds the plastic as its being heated. Then once the piece is heated you push the frame over the vacuum box, which will pull the plastic over the plug (mold of what you want to be made).

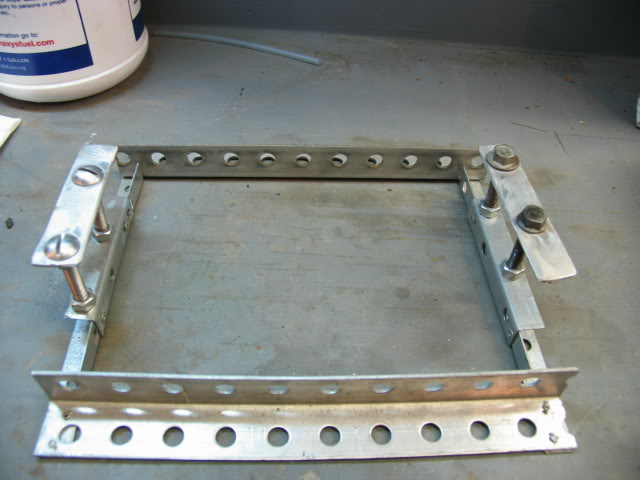

This is what a finished frame will look like:

You can design it anyway you like just make sure its big enough to fit the peice you want, but not too small that it wont fit around the box.

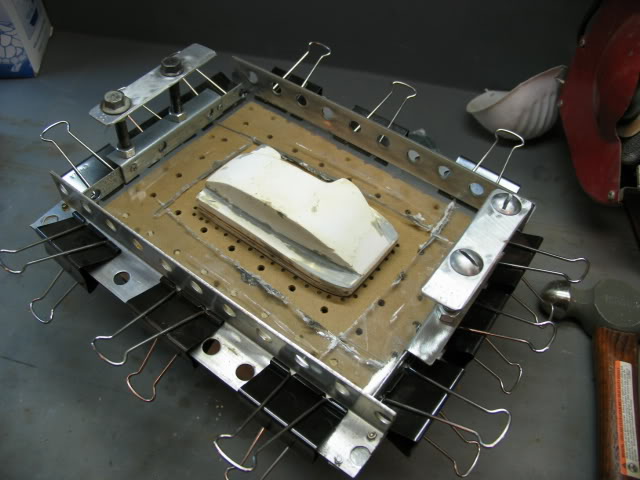

The box is the key part.

To make it you will need to first figure out the dimensions you want. Then after that build a basic cube, make sure it has enough room inside for pressure too build up but not so big that the pressure takes forever to build up because then your plastic will have cooled and become hard again. Before you put the lid on seal the entire crack with a caulk so the pressure can build up better. Use glue in all the seams and when putting the lid on put a bead of caulk down then screw it on. Make sure the lid has a good amount of holes in it and around the piece you are making you might need to make multiple tiny holes like you see I did. These holes allow the suction to pull the plastic around your mold better. The final step is to drill a hole in the side the diameter of your vacuum hose. i used a central vacuum system and it had plenty of vacuum to pull down 1/8" Plexiglas, I am sure a wet vacuum would also be suitable for the application. Also you might have to brace the lid inside if the box gets bigger then what I made, a simple block inside the center would work just so the lid doesn’t flex down as the suction is occurring.

The next thing that needs to be made is the mold. The mold HAS to be extremely smooth or else the imperfections will be molded into the piece and you will see them. If the piece chips on you use JB weld to fill the crack and sand it smooth. Spend a good amount of time on the mold, the smoother it is the better your final product will come out.

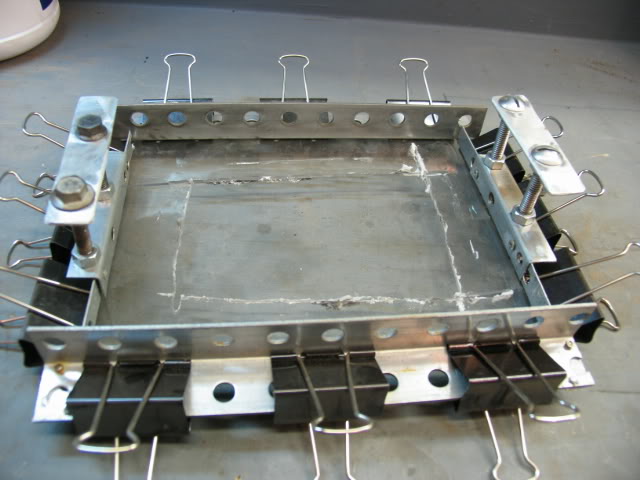

Ok now you need to heat the plastic. I did not have a full piece of Plexiglas for the pictures but you will get the idea the center is just cut out from an old mold. Clip the piece of plastic to your frame, make sure it is secure and the clips are close or else the vacuum might pull it off the frame.

Now you will need to suspend the frame in the oven while it is heating. i used a metal pan for this since the frame was not very big.

To heat it put your oven on BROIL and put the frame in the middle of the oven with all the other grates removed. Close the door but keep the light on. Watch the piece, once you see it start to droop its almost time. It will be a trial and error experience from here on; I can’t really describe the perfect time to take the plastic out so you will just have to experiment. But if you do it too long the piece will bubble and look horrible and if heated too little it will not form properly.

If you have two people for this step you will thank yourself. Have your partner turn on the vacuum and hold the box in place. You grab the frame out of the oven with gloves on (that’s why there is handles much easier to grab). Do this process quickly or else the plastic will cool. Push the frame over the box, the plastic will wrap over the mold and the vacuum will pull it down. Make sure the frame goes below the lid line of the box or else there wont be a seal made of plastic to box and the suction wont occur. Let the vacuum pull on the piece till it dries for best results. You might thane to get a wide chisel or something metal and flat to push into the corners, I had to for some convex parts since the material was rather thick.

Now just pull the plastic off the mold and cut your piece out and you are finished. As I said earlier though this is what I did for my specific piece, you will have to modify it for different pieces and different materials but it will give you a barebones idea of what is needed to vacuum form with things found around the home. The next thing I am going to do is make some bodies I think.

Finished product after being cut out:

Materials needed:

1.Angle Iron

2.Big office Clips

3.Plaster of Paris

4.Big aluminum tray

5.Misc wood scraps

6.Caulk

7.Different sandpapers, ranging from fine to very fine

8.Misc tools to build everything

9.Oven or other heat source (toaster oven)

The first couple of things that you will need to build are the frame and box. The frame has to be slightly bigger then the box or else the whole process won’t work. the frame is what holds the plastic as its being heated. Then once the piece is heated you push the frame over the vacuum box, which will pull the plastic over the plug (mold of what you want to be made).

This is what a finished frame will look like:

You can design it anyway you like just make sure its big enough to fit the peice you want, but not too small that it wont fit around the box.

The box is the key part.

To make it you will need to first figure out the dimensions you want. Then after that build a basic cube, make sure it has enough room inside for pressure too build up but not so big that the pressure takes forever to build up because then your plastic will have cooled and become hard again. Before you put the lid on seal the entire crack with a caulk so the pressure can build up better. Use glue in all the seams and when putting the lid on put a bead of caulk down then screw it on. Make sure the lid has a good amount of holes in it and around the piece you are making you might need to make multiple tiny holes like you see I did. These holes allow the suction to pull the plastic around your mold better. The final step is to drill a hole in the side the diameter of your vacuum hose. i used a central vacuum system and it had plenty of vacuum to pull down 1/8" Plexiglas, I am sure a wet vacuum would also be suitable for the application. Also you might have to brace the lid inside if the box gets bigger then what I made, a simple block inside the center would work just so the lid doesn’t flex down as the suction is occurring.

The next thing that needs to be made is the mold. The mold HAS to be extremely smooth or else the imperfections will be molded into the piece and you will see them. If the piece chips on you use JB weld to fill the crack and sand it smooth. Spend a good amount of time on the mold, the smoother it is the better your final product will come out.

Ok now you need to heat the plastic. I did not have a full piece of Plexiglas for the pictures but you will get the idea the center is just cut out from an old mold. Clip the piece of plastic to your frame, make sure it is secure and the clips are close or else the vacuum might pull it off the frame.

Now you will need to suspend the frame in the oven while it is heating. i used a metal pan for this since the frame was not very big.

To heat it put your oven on BROIL and put the frame in the middle of the oven with all the other grates removed. Close the door but keep the light on. Watch the piece, once you see it start to droop its almost time. It will be a trial and error experience from here on; I can’t really describe the perfect time to take the plastic out so you will just have to experiment. But if you do it too long the piece will bubble and look horrible and if heated too little it will not form properly.

If you have two people for this step you will thank yourself. Have your partner turn on the vacuum and hold the box in place. You grab the frame out of the oven with gloves on (that’s why there is handles much easier to grab). Do this process quickly or else the plastic will cool. Push the frame over the box, the plastic will wrap over the mold and the vacuum will pull it down. Make sure the frame goes below the lid line of the box or else there wont be a seal made of plastic to box and the suction wont occur. Let the vacuum pull on the piece till it dries for best results. You might thane to get a wide chisel or something metal and flat to push into the corners, I had to for some convex parts since the material was rather thick.

Now just pull the plastic off the mold and cut your piece out and you are finished. As I said earlier though this is what I did for my specific piece, you will have to modify it for different pieces and different materials but it will give you a barebones idea of what is needed to vacuum form with things found around the home. The next thing I am going to do is make some bodies I think.

Finished product after being cut out: