I wasn’t going to do any engine mods on this Force .21 engine for a Ofna Ultra MBX R2 but that didn’t last too long.

First up on my engine mods is the head button work.

Now before Greywolf chimes in, let me give him a history lesson on how the turbo head buttons came around, and why I do this to my heads.

In the 80’s we had what’s called a KEELEY TURBO HEAD BUTTON, manufactured in Canada. It is the first turbo head and it used regular long glow plugs (You didn’t have to buy a specific turbo head plug). Its design was to direct the fuel to the glow plug, allow the piston to work less to compress the fuel charge as the squish band was rather narrow and angled vs a flat sharp edge, and allow the “fuel rich” return supercharged exhaust to have an easier pathway to the combustion chamber, hence why the exhaust has the most removed surface. See the pic of the black head button.

Now that’s out of the way.

I do a similar mod to my head buttons but not as aggressive.

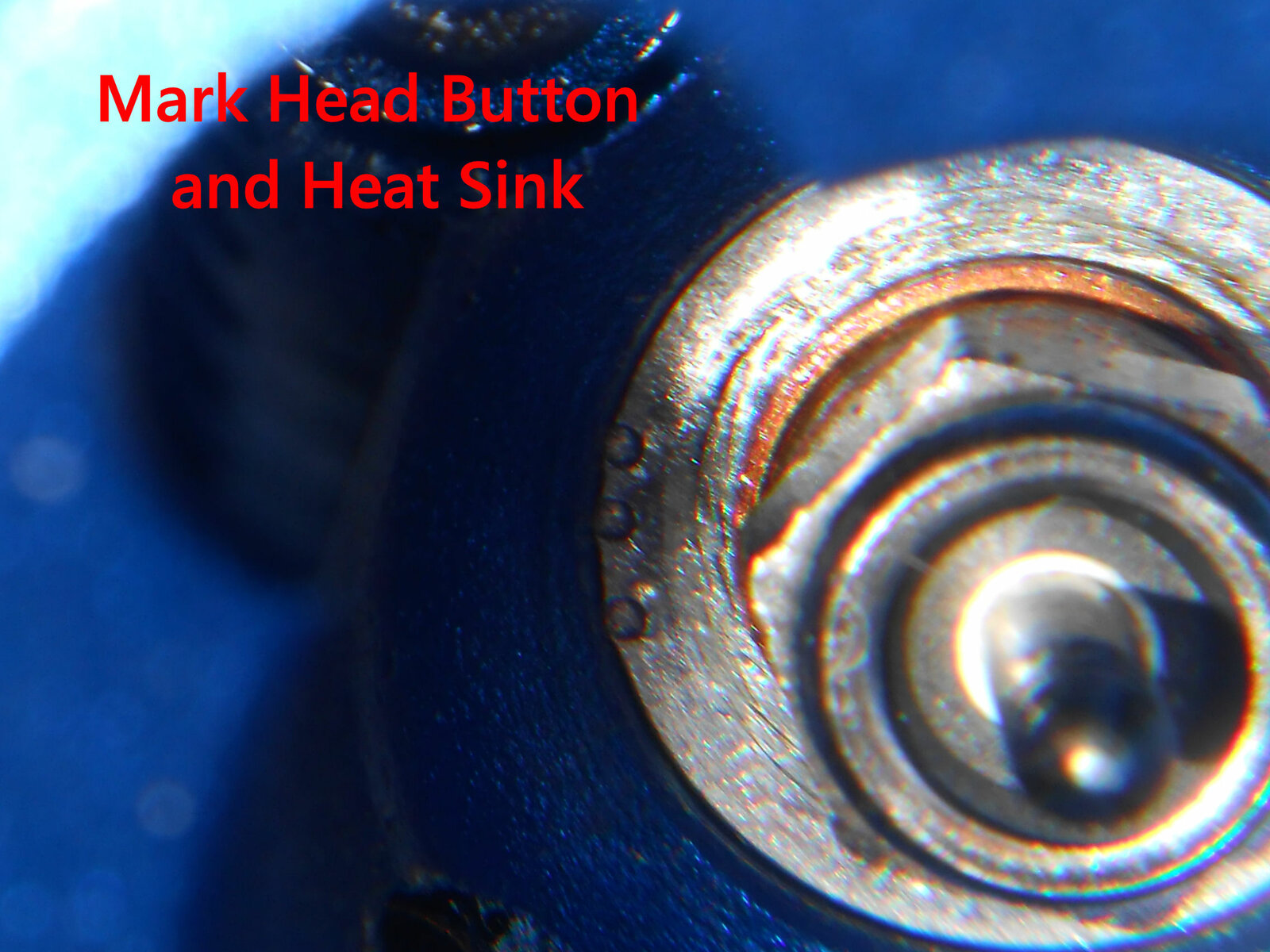

First, I mark the head button and heat sink. (Never take an engine apart without marking it). I mark the exhaust port side of the head button, so I know where to start. If you look really closely, I also marked the heatsink, so the head and heatsink, go back on the block 100% the way it was manufactured and assembled.

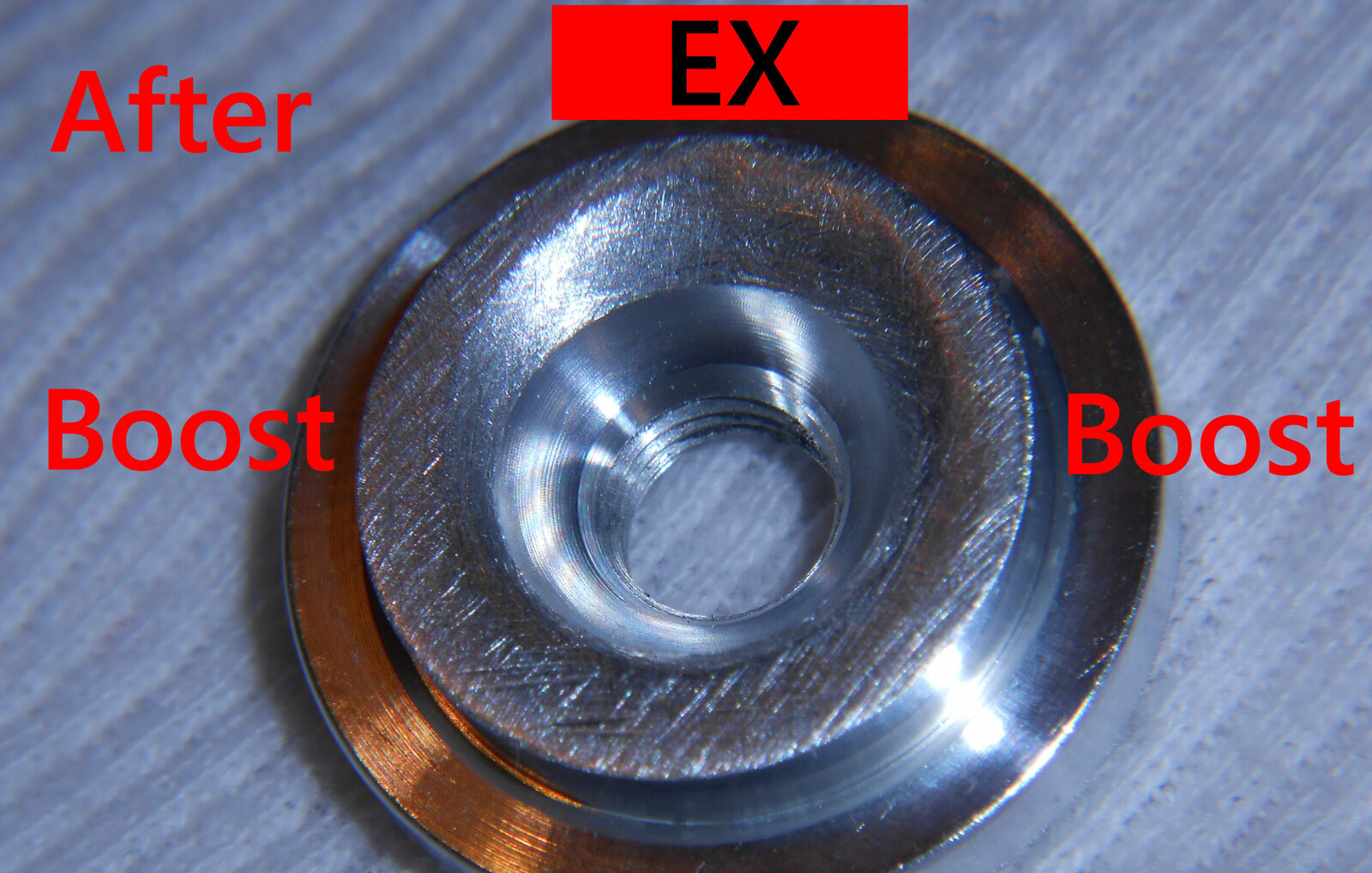

I smooth out the sharp edge of the combustion chamber’s squish band. While doing so, I dome out the exhaust side of the combustion chamber leaving only a little bit of the squish band flat, and I do the same for the boost ports but not as much material removed.

I do not remove material from the depth of the squish band, the squish bands depth is the same, just rounded the sharp edge some.

The intake, I somewhat just round out the sharp edge so the fuel that is being compressed has a smooth transition from the squish band, then up into the combustion chamber. But the whole sharp edge diameter gets rounded and scuffed up. Scuffed up is for drag as it lessens the internal drag of the fuel during the squish and chamber transition.

Knowing the head shims do not seal the head I know I can remove them and run the head alone.

I remove the head shims to compensate for the material I removed.

Keep in mind I run high content fuel, 40 to 65, and am known for running propylene oxide instead of methanol as an igniter (But don’t tell no one).

I already decided to run 50% Red Max fuel, so I know I have to decompress the engine some (Add head shims).

Well instead of adding head shims, I remove a slight amount of material to give me the extra head space I need to run 50%.

I been doing this for 37 years and never had an engine fail, or a rod break. Yes, I am decompressing the engine to gain RPM. I will gain 2000 (Stock tuned pipe length) to 4000 rpm (If I lengthen the pipe) right off the rip, and on 30% so with 50% those numbers go up.

I know you guys don’t talk about “Tuned” pipe length on buggies. That’s what the pipe is for, to tune to the pulse of the engine, not just bolt on and hope for the best. You tune the pipe, that’s why they are called tuned pipes.

I wouldn't suggest anyone do this.

But I do it to every head I ever had. It really lets the engine breath and exhale.

I spoke with Keeles not to long ago he sold me some old stock turbo heads he had laying around for my K&B engines. Nice guy. Even if I don't do any other mods to the sleeve or engine in general, they all get my version of the original turbo head.

I guess in a manufacturing standpoint, it's cheaper to mill a plug and head than to do all this work. So, I understand why he doesn't manufacture them anymore. But this is the head button that gave birth to what we now know as the Turbo Head.

A lot of you guys never knew this......

First up on my engine mods is the head button work.

Now before Greywolf chimes in, let me give him a history lesson on how the turbo head buttons came around, and why I do this to my heads.

In the 80’s we had what’s called a KEELEY TURBO HEAD BUTTON, manufactured in Canada. It is the first turbo head and it used regular long glow plugs (You didn’t have to buy a specific turbo head plug). Its design was to direct the fuel to the glow plug, allow the piston to work less to compress the fuel charge as the squish band was rather narrow and angled vs a flat sharp edge, and allow the “fuel rich” return supercharged exhaust to have an easier pathway to the combustion chamber, hence why the exhaust has the most removed surface. See the pic of the black head button.

Now that’s out of the way.

I do a similar mod to my head buttons but not as aggressive.

First, I mark the head button and heat sink. (Never take an engine apart without marking it). I mark the exhaust port side of the head button, so I know where to start. If you look really closely, I also marked the heatsink, so the head and heatsink, go back on the block 100% the way it was manufactured and assembled.

I smooth out the sharp edge of the combustion chamber’s squish band. While doing so, I dome out the exhaust side of the combustion chamber leaving only a little bit of the squish band flat, and I do the same for the boost ports but not as much material removed.

I do not remove material from the depth of the squish band, the squish bands depth is the same, just rounded the sharp edge some.

The intake, I somewhat just round out the sharp edge so the fuel that is being compressed has a smooth transition from the squish band, then up into the combustion chamber. But the whole sharp edge diameter gets rounded and scuffed up. Scuffed up is for drag as it lessens the internal drag of the fuel during the squish and chamber transition.

Knowing the head shims do not seal the head I know I can remove them and run the head alone.

I remove the head shims to compensate for the material I removed.

Keep in mind I run high content fuel, 40 to 65, and am known for running propylene oxide instead of methanol as an igniter (But don’t tell no one).

I already decided to run 50% Red Max fuel, so I know I have to decompress the engine some (Add head shims).

Well instead of adding head shims, I remove a slight amount of material to give me the extra head space I need to run 50%.

I been doing this for 37 years and never had an engine fail, or a rod break. Yes, I am decompressing the engine to gain RPM. I will gain 2000 (Stock tuned pipe length) to 4000 rpm (If I lengthen the pipe) right off the rip, and on 30% so with 50% those numbers go up.

I know you guys don’t talk about “Tuned” pipe length on buggies. That’s what the pipe is for, to tune to the pulse of the engine, not just bolt on and hope for the best. You tune the pipe, that’s why they are called tuned pipes.

I wouldn't suggest anyone do this.

But I do it to every head I ever had. It really lets the engine breath and exhale.

I spoke with Keeles not to long ago he sold me some old stock turbo heads he had laying around for my K&B engines. Nice guy. Even if I don't do any other mods to the sleeve or engine in general, they all get my version of the original turbo head.

I guess in a manufacturing standpoint, it's cheaper to mill a plug and head than to do all this work. So, I understand why he doesn't manufacture them anymore. But this is the head button that gave birth to what we now know as the Turbo Head.

A lot of you guys never knew this......