ChuChu

RCTalk Rookie

- Messages

- 20

- Reaction score

- 7

Hi,

I decided to create this topic, because I still have too many questions and do not want to create more and more topics...

I am total newbie but with some mechanical knowledge and skills, mainly from cycling. I spent last 9 years on stripping down every bike part to undestand how it works.

I started with Racing Fighter kit but read a lot and decided to go with some Hop Ups. I have luck that Tamiya distributor in my country has shop 10 minutes from my home.

Kit was supplied with Torque Tuned engine, CVA dampers and ESC. I bought:

- Aluminium Bridges

- Sway Bars

- Aluminium Servo Mount

- High Torque Servo Saver

- Ball Bearings ( Tamiya + 1$ generic)

- CVA dampers... Shop told me that there are friction shock in kit, so I bought CVA...

- Hard suspension oil

- Aluminium Cover for Servo Saver

- Aluminium M4 wheels bolts

- Aluminium M3 for Servo Saver

- 12 Aluminium Hex for rear wheels

- 0.1 0.2 0.3 0.5 shims

Some of them just for "bling", some because I read a lot reccomendations.

Today I ordered light gearbox shaft but I will install them next time. I do not want to strip down gearbox again.

Progress photos:

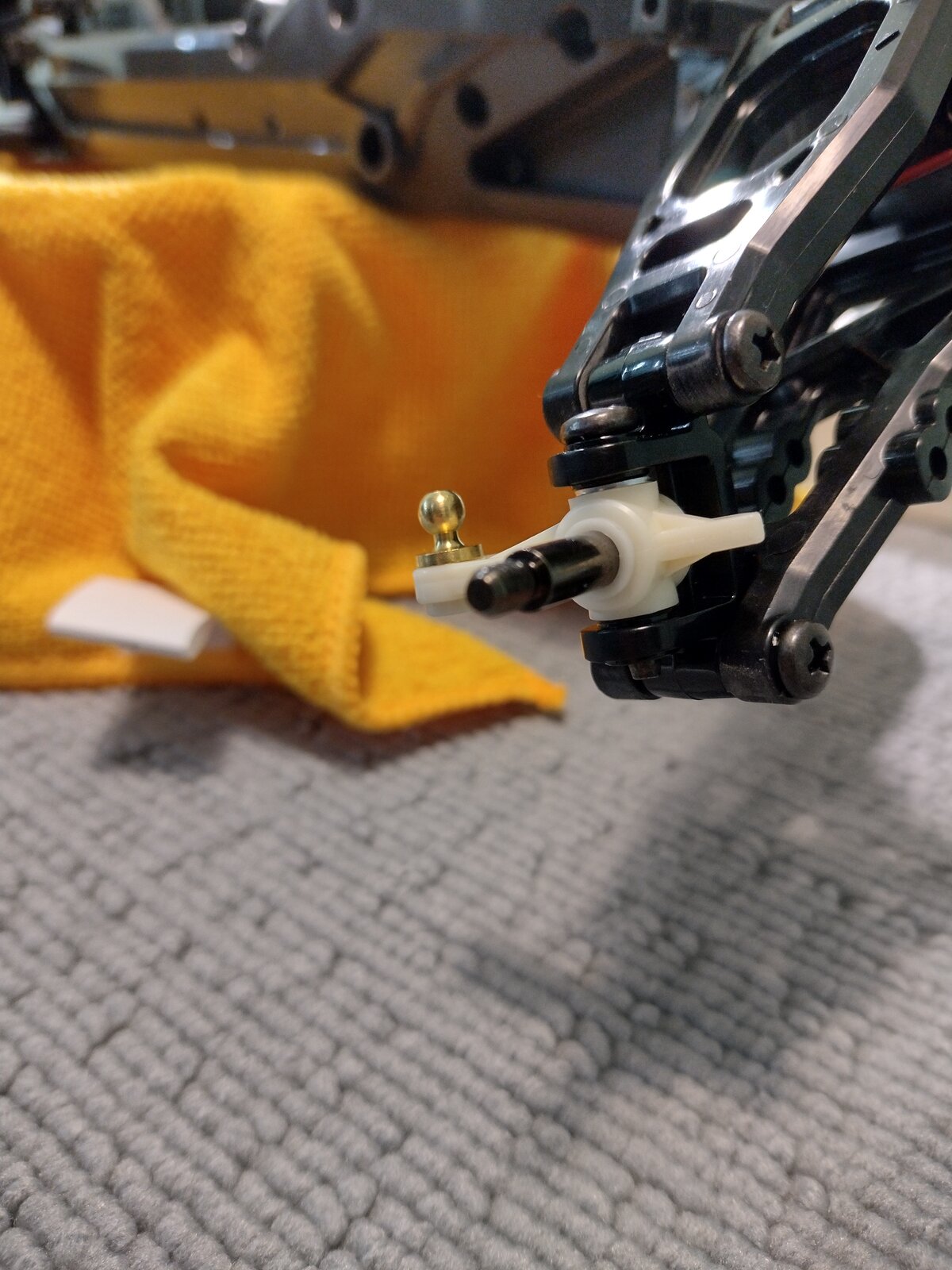

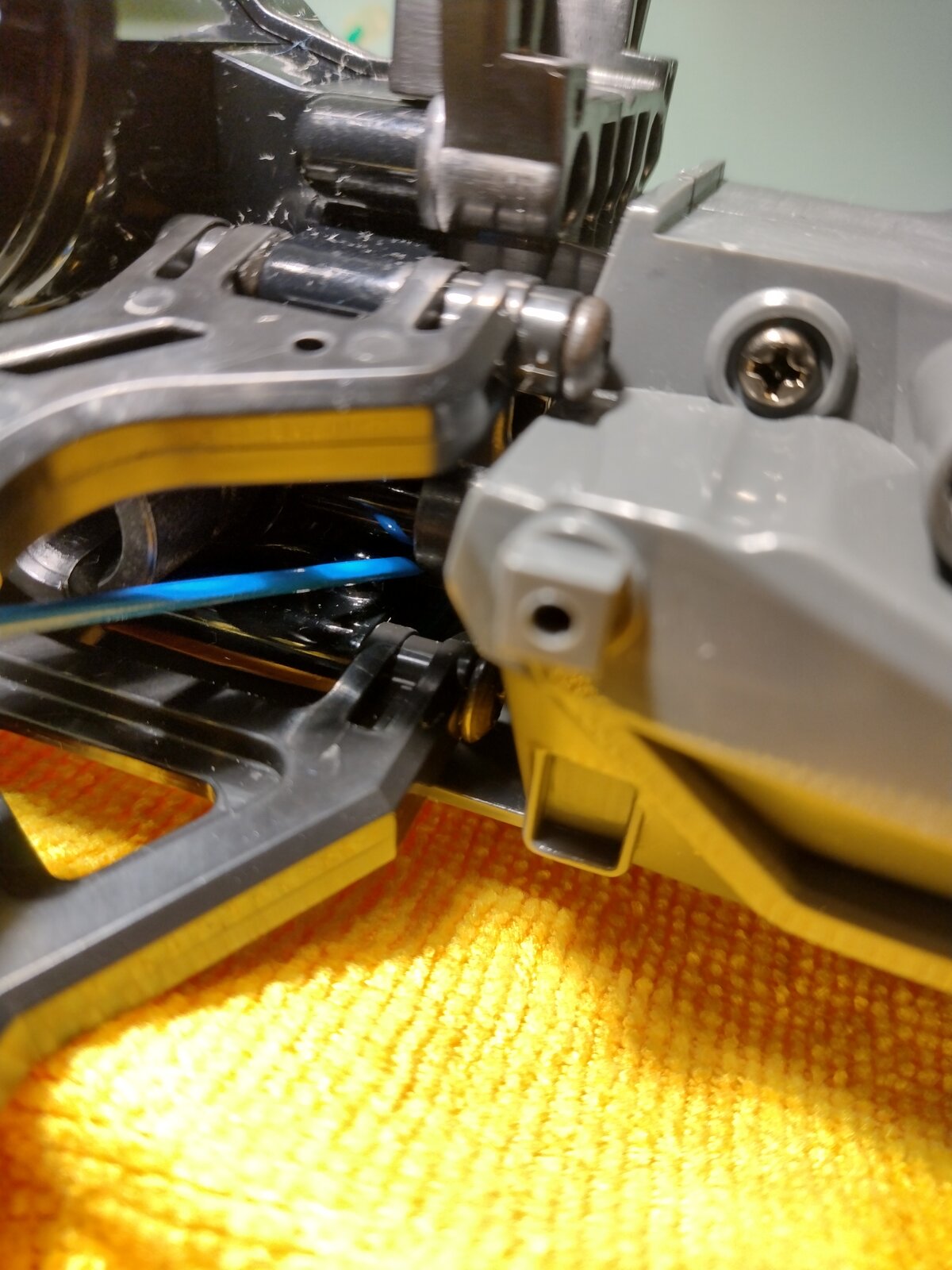

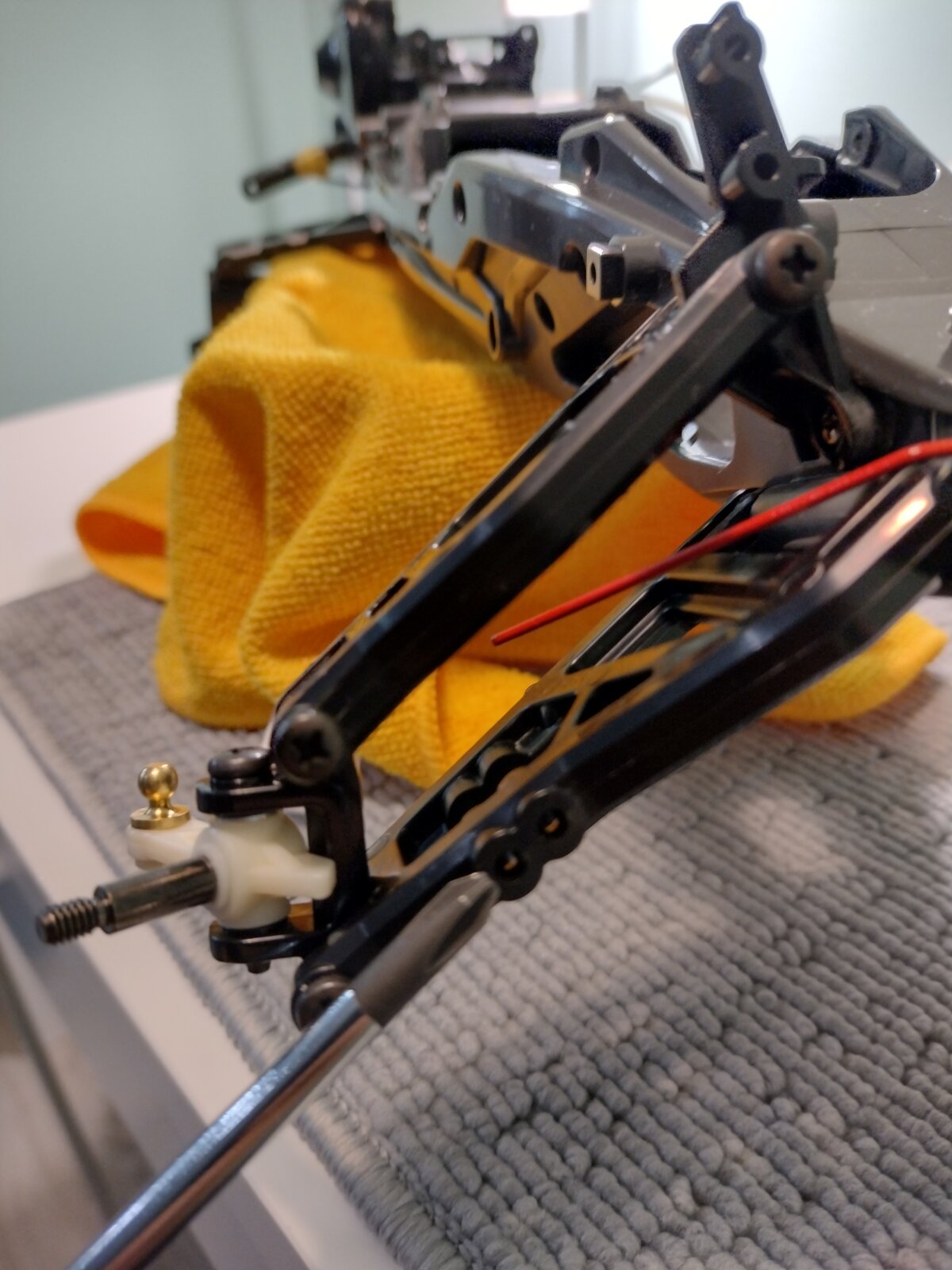

Shims in suspension. I tried to leave around 0.1 mm of play. I used wax on shafts to reduce friction. All parts are sanded down on contact surfaces.

Plan is to buy all Hop Ups I want to install them now and not to disassembly model each month to put something new.

Of course as newbie I did few mistakes. Nothing big, but still. I diff I used M3 screws instead of M2.6. Works fine so no big deal. Worse is that I installed bottom rear wishbones shafts from wrong side. It works fine but I do not have access to them. Upper shafts are installed correctly but on the same side. So in the end to do something with wishbones I have to remove gearbox.

I wanted few more things like stainless steel suspensions shafts but unfortunately they are not available in my country. I also wanted metal drivetrains shafts but again, not all parts are available.

Questions time!

Can I use both holes to install shocks ( front and rear) or should I stick to manual?

I have also problem with Servo Saver but I will do photos tommorow when light be better...

I decided to create this topic, because I still have too many questions and do not want to create more and more topics...

I am total newbie but with some mechanical knowledge and skills, mainly from cycling. I spent last 9 years on stripping down every bike part to undestand how it works.

I started with Racing Fighter kit but read a lot and decided to go with some Hop Ups. I have luck that Tamiya distributor in my country has shop 10 minutes from my home.

Kit was supplied with Torque Tuned engine, CVA dampers and ESC. I bought:

- Aluminium Bridges

- Sway Bars

- Aluminium Servo Mount

- High Torque Servo Saver

- Ball Bearings ( Tamiya + 1$ generic)

- CVA dampers... Shop told me that there are friction shock in kit, so I bought CVA...

- Hard suspension oil

- Aluminium Cover for Servo Saver

- Aluminium M4 wheels bolts

- Aluminium M3 for Servo Saver

- 12 Aluminium Hex for rear wheels

- 0.1 0.2 0.3 0.5 shims

Some of them just for "bling", some because I read a lot reccomendations.

Today I ordered light gearbox shaft but I will install them next time. I do not want to strip down gearbox again.

Progress photos:

Shims in suspension. I tried to leave around 0.1 mm of play. I used wax on shafts to reduce friction. All parts are sanded down on contact surfaces.

Plan is to buy all Hop Ups I want to install them now and not to disassembly model each month to put something new.

Of course as newbie I did few mistakes. Nothing big, but still. I diff I used M3 screws instead of M2.6. Works fine so no big deal. Worse is that I installed bottom rear wishbones shafts from wrong side. It works fine but I do not have access to them. Upper shafts are installed correctly but on the same side. So in the end to do something with wishbones I have to remove gearbox.

I wanted few more things like stainless steel suspensions shafts but unfortunately they are not available in my country. I also wanted metal drivetrains shafts but again, not all parts are available.

Questions time!

Can I use both holes to install shocks ( front and rear) or should I stick to manual?

I have also problem with Servo Saver but I will do photos tommorow when light be better...