- Thread starter

- #21

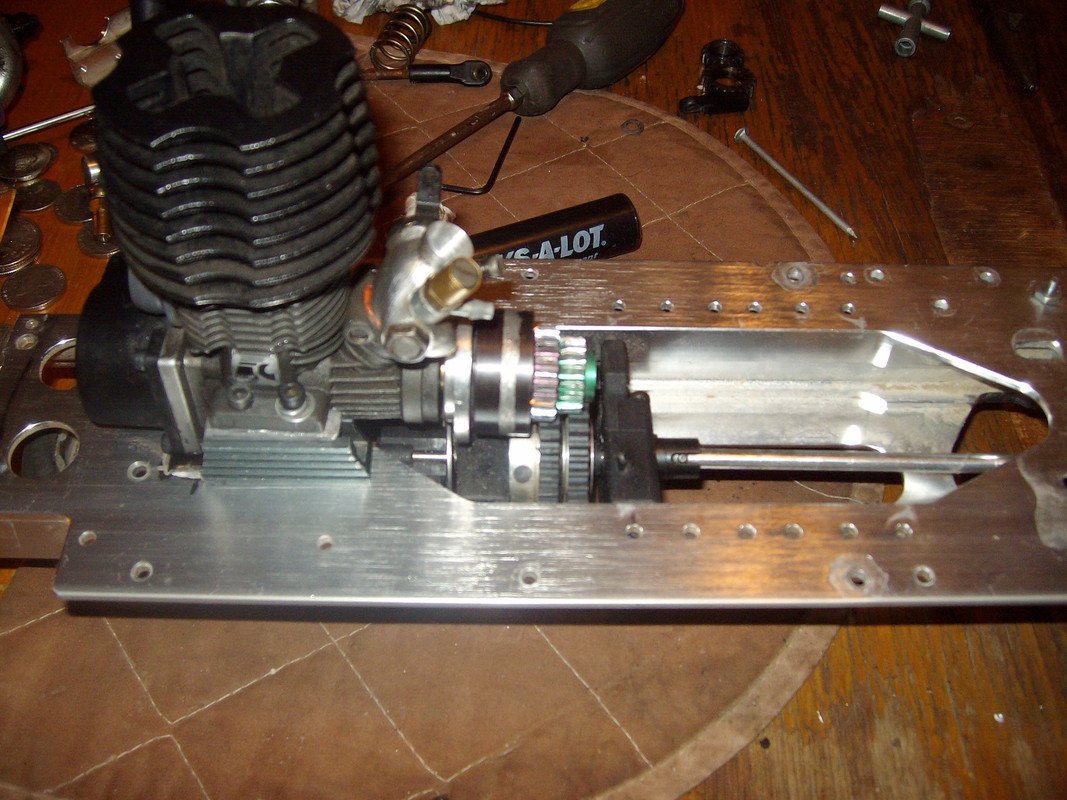

Kyosho pureten alpha 2 speed transmission /bell kit ,fitted to a cen nt-16 engine, had to swap the owb from a 14mm to 12mm one so the kit bell would fit ,was all pretty straight forward realy .... just need to fab up a little fixing plate for the engine/chassis or could just drill 4 new holes in the chassis and bolt it on like the original kyosho gx12 .... whats your thoughts ?? Drill holes or make a engine mount ??