Nitrotrout

Nitro Junkie

Supporter

I've been a Thunder Tiger buggy enthusiast for well over 10 years now.

But the model I always wanted but could never locate was the ever elusive and rare EK4 S2.

Finally, after years of searching I found a complete 2004 model EK4 S2 Sport reasonably priced so I jumped on it.

Objective: My plan is to convert a rare and unusual old school truck into a durable, modernized, truggy style basher.

Background: History of the EK4 is blurry because they were short lived and discontinued rather quickly. What I gather so far is, the EK4 was offered from 2004-2006 at a cost of $700.00 retail. I can't confirm if this true though. What I do know is, the EK4 had a fair share of issues.

The Pro .70 helicopter engine was notorious for overheating. The lack of a center diff combined with the torque of the .70 engine often destroyed clutches and diffs. The unusual diameter and deep dish design of the wheels made tire and wheel selection difficult. Possibly the biggest complaint with the EK4 truck was the lack of replacement parts. This is true to a certain degree.

The EK4 is actually an EB4 S2 Buggy with monster truck accessories.Difference being, the EK4 has an extended rear bumper, deep dish monster truck wheels, front shock replacing the sway bar, and two additional rear shocks. The EK4 has slightly different shock towers and body mounts to accommodate a truck body, a center rigid axle replacing the center diff and a monstrous .70 helicopter engine replacing the Pro .21 engine. With the simple addition of a few MT parts, the EK4 could arguably be one of the first ever production truggies.

Although the part numbers differ, the EB4/ EK4 share identical suspension, chassis, and running gear components making parts replacement fairly easy.

A majority of replacement parts for my project are EB4 S2 parts that I found cheap and readily available on ebay.

Parts not so readily available: The original truck body,the rear bumper, Pro .70BX crank case, crank shaft, clutch assembly, carb, front and rear lower shock mounts, wheels and tires.

SO HERE'S MY CANVAS: KINDA CARTOONISH LOOKING NOW BUT I INTEND TO CHANGE ALL THAT

HORIZONTALLY MOUNTED SHOCK (BEHIND FRONT SKID) USED AS A FRONT SWAY CONTROL

DEEP DISH WHEELS WERE USED INSTEAD OF EXTENDED CONTROL ARMS TO WIDEN THE OVERALL TRACK WIDTH

HUGE EXTENDED REAR BUMPER WORKS AS A WHEELIE BAR

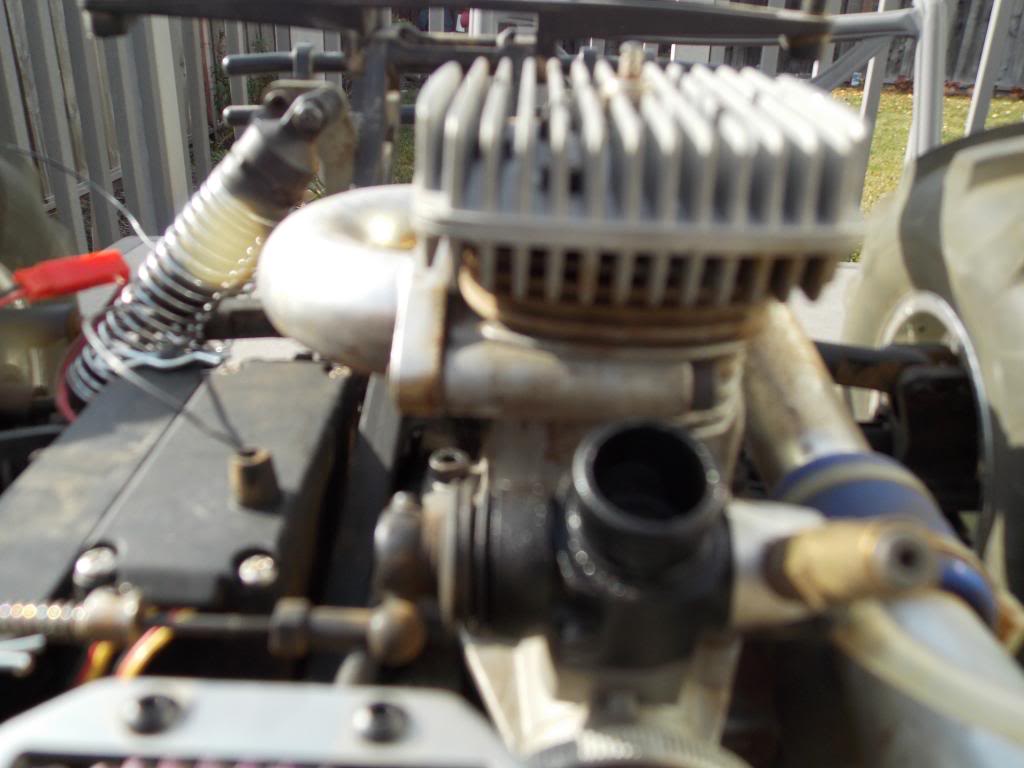

NOTICE THE FLAT HEAD DESIGN OF THE COOLING HEAD. THIS IN COMBO WITH NO CUT OUTS IN THE BODY CREATED

THE HEATING PROBLEMS I SUSPECT

MONSTEROUS 12v STARTER, OWNERS MANUAL AND A REALLY COOL COMBO WRENCH

WERE INCLUDED WITH THE TRUCKJ

CURRENTLY WEIGHS 10lbs 12oz. I'M GONNA TRY TO LIGHTEN HER UP A BIT.

But the model I always wanted but could never locate was the ever elusive and rare EK4 S2.

Finally, after years of searching I found a complete 2004 model EK4 S2 Sport reasonably priced so I jumped on it.

Objective: My plan is to convert a rare and unusual old school truck into a durable, modernized, truggy style basher.

Background: History of the EK4 is blurry because they were short lived and discontinued rather quickly. What I gather so far is, the EK4 was offered from 2004-2006 at a cost of $700.00 retail. I can't confirm if this true though. What I do know is, the EK4 had a fair share of issues.

The Pro .70 helicopter engine was notorious for overheating. The lack of a center diff combined with the torque of the .70 engine often destroyed clutches and diffs. The unusual diameter and deep dish design of the wheels made tire and wheel selection difficult. Possibly the biggest complaint with the EK4 truck was the lack of replacement parts. This is true to a certain degree.

The EK4 is actually an EB4 S2 Buggy with monster truck accessories.Difference being, the EK4 has an extended rear bumper, deep dish monster truck wheels, front shock replacing the sway bar, and two additional rear shocks. The EK4 has slightly different shock towers and body mounts to accommodate a truck body, a center rigid axle replacing the center diff and a monstrous .70 helicopter engine replacing the Pro .21 engine. With the simple addition of a few MT parts, the EK4 could arguably be one of the first ever production truggies.

Although the part numbers differ, the EB4/ EK4 share identical suspension, chassis, and running gear components making parts replacement fairly easy.

A majority of replacement parts for my project are EB4 S2 parts that I found cheap and readily available on ebay.

Parts not so readily available: The original truck body,the rear bumper, Pro .70BX crank case, crank shaft, clutch assembly, carb, front and rear lower shock mounts, wheels and tires.

SO HERE'S MY CANVAS: KINDA CARTOONISH LOOKING NOW BUT I INTEND TO CHANGE ALL THAT

HORIZONTALLY MOUNTED SHOCK (BEHIND FRONT SKID) USED AS A FRONT SWAY CONTROL

DEEP DISH WHEELS WERE USED INSTEAD OF EXTENDED CONTROL ARMS TO WIDEN THE OVERALL TRACK WIDTH

HUGE EXTENDED REAR BUMPER WORKS AS A WHEELIE BAR

NOTICE THE FLAT HEAD DESIGN OF THE COOLING HEAD. THIS IN COMBO WITH NO CUT OUTS IN THE BODY CREATED

THE HEATING PROBLEMS I SUSPECT

MONSTEROUS 12v STARTER, OWNERS MANUAL AND A REALLY COOL COMBO WRENCH

WERE INCLUDED WITH THE TRUCKJ

CURRENTLY WEIGHS 10lbs 12oz. I'M GONNA TRY TO LIGHTEN HER UP A BIT.

Last edited: