- Messages

- 540

- Reaction score

- 889

- Location

- Western Washington

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

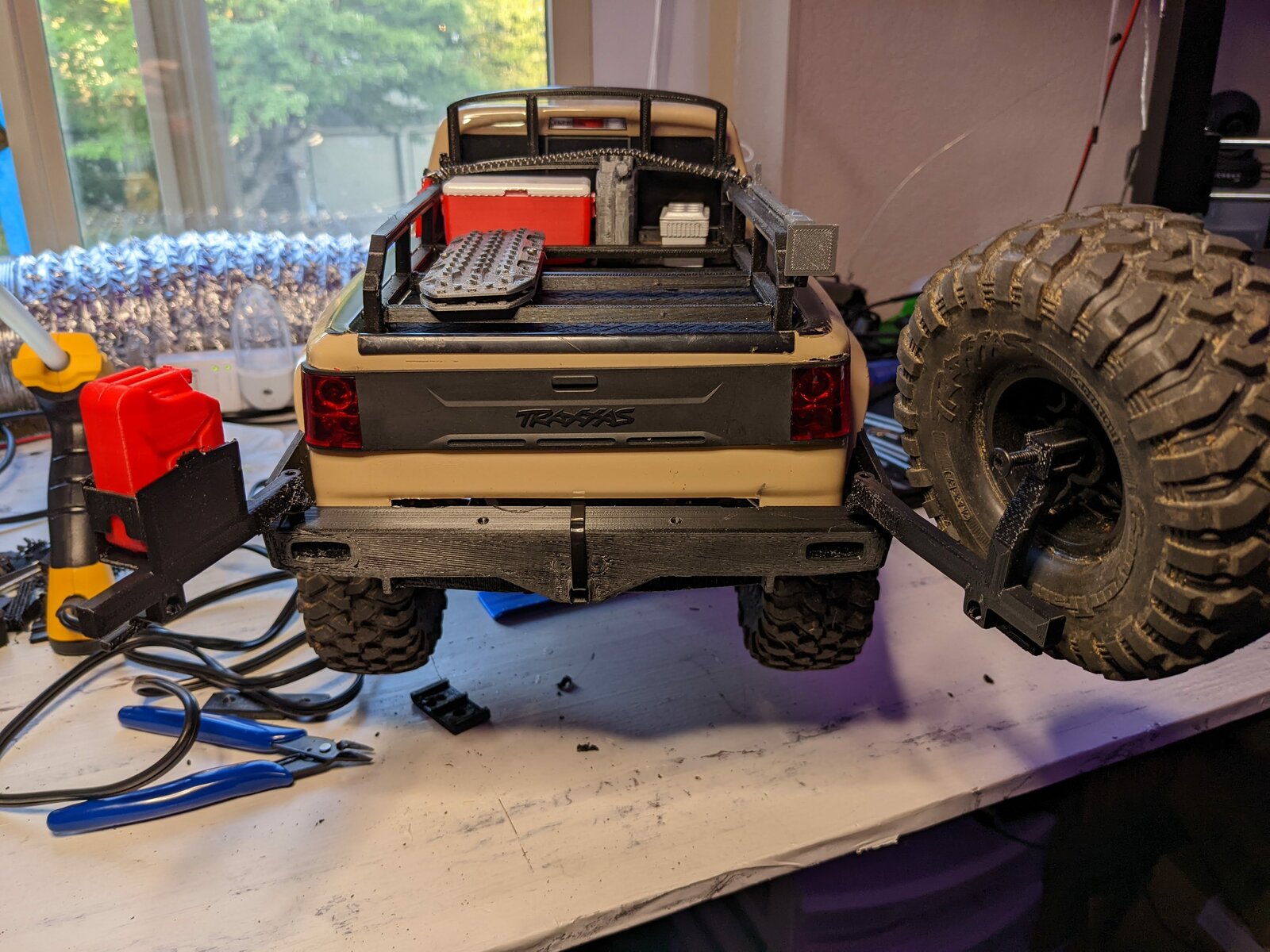

When I bought my TRX4 Sport I had planned on dumping the factory body and going to an actual branded body. Somewhere along the way I decided I really like the Sport body and decided to build on it for a while. Everyone thinks it's a standard cab Tacoma anyway.

I'll add some photos at the bottom but basically, I've added aluminum axle housings from Yeah Racing, and some Treal caster blocks after I broke one of the front housings in the snow. Nothing much done to it other than a Hobbywing 1080.

After I picked up a 3D printer things have progressed faster. I added the lighting kit when I got the truck but I'm currently in the process of kitting the truck out with a dual swingout rear bumper I'm modifying to be a direct fit, the bed rack which I'm going to swap the headache rack over to a low bar setup instead because it's fugly at some angles, and an ARB style front bumper that will get a winch in it by the time it's done.

The pictures are all pretty much mockup at this point. I got some of the redesign done over the weekend but the rear bumper print failed 4 times so I moved back to the front. All of the small accessory parts are from a file pack I pulled from Thiniverse and the bumper models started as https://www.thingiverse.com/4am_engineering/designs models that I have modified/am modifying in Tinkercad, as you can see in the pics I changed the Jerrycan holder orientation and doubled it to make room for the spare and allow me to move the spare closer to center.

The design and printing side is all still pretty new to me so just getting a part to fit feels like a victory at this point.

I'll add some photos at the bottom but basically, I've added aluminum axle housings from Yeah Racing, and some Treal caster blocks after I broke one of the front housings in the snow. Nothing much done to it other than a Hobbywing 1080.

After I picked up a 3D printer things have progressed faster. I added the lighting kit when I got the truck but I'm currently in the process of kitting the truck out with a dual swingout rear bumper I'm modifying to be a direct fit, the bed rack which I'm going to swap the headache rack over to a low bar setup instead because it's fugly at some angles, and an ARB style front bumper that will get a winch in it by the time it's done.

The pictures are all pretty much mockup at this point. I got some of the redesign done over the weekend but the rear bumper print failed 4 times so I moved back to the front. All of the small accessory parts are from a file pack I pulled from Thiniverse and the bumper models started as https://www.thingiverse.com/4am_engineering/designs models that I have modified/am modifying in Tinkercad, as you can see in the pics I changed the Jerrycan holder orientation and doubled it to make room for the spare and allow me to move the spare closer to center.

The design and printing side is all still pretty new to me so just getting a part to fit feels like a victory at this point.