coldvod

RCTalk Talkaholic

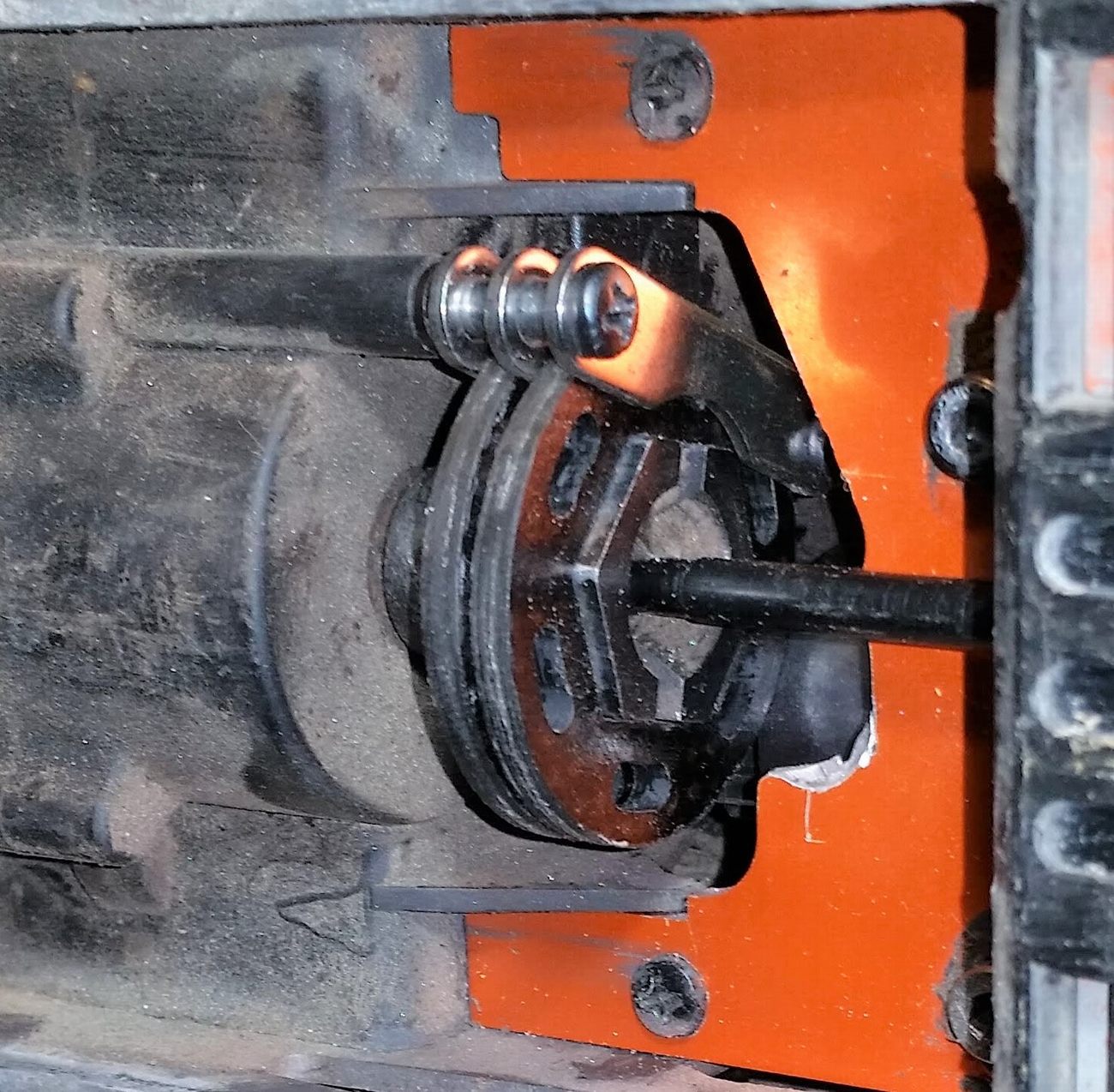

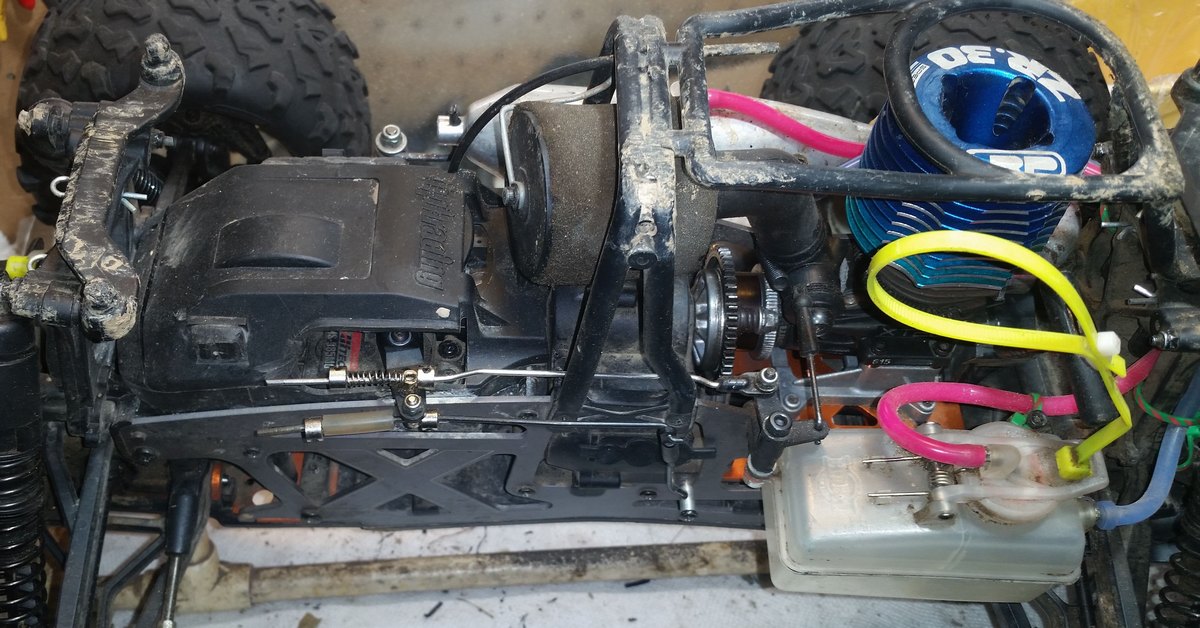

It's fun but I don't have brakes. I'm lazy and I don't feel like taking the whole brake, transmission and stuff etc. off my vehicle. Basically the brake linkage doesn't press the pad/compress it. The servo moves it. If you need me to provide video and/or photos I will provide them but at the moment it's 9pm and I don't feel like troubleshooting an rc car. Any help is appreciated