CharliesTheMan

Gone - bye bye.

This is a project that has been on the backburner for a while. Part of building a competitive crawler from scratch is that when it comes time to start mounting all of the different parts that weren't designed to work together, there's no way to have all of the hardware that you need and little doo-dads, things like that. The build has been a long process because I would have everything ready to go and start installing something to realize that my screws were 1/8 inch too short, then I would have to make a trip to the bolt store and order them, etc...

Also, I'm now a sponsored driver for East End Machining. Now you guys know how much I like to drive old beat up RC's put together with bailing wire and duct tape, but when you are a sponsored driver, it's your obligation to have a top of the line rig in tip top shape.

I've gone with a lot of STRC parts for this build, and I'm hooked. I was a little wary of buying from a big name brand company because integy put such a bad taste in my mouth. Boy was I wrong! I absolutely love every STRC part that I've had, and the counts now up to around 15 different parts between all of my rigs. The fit and finish is impeccable, the customer service is excellent, and the parts are absolutely beautiful and perform to the highest standard.

First things first, I had a long day yesterday and didn't get started on the truck until yet, so I guzzled a NOS energy drink, only the best, grape flavored. Breakfast of champions, and lunch and dinner of Charlie!

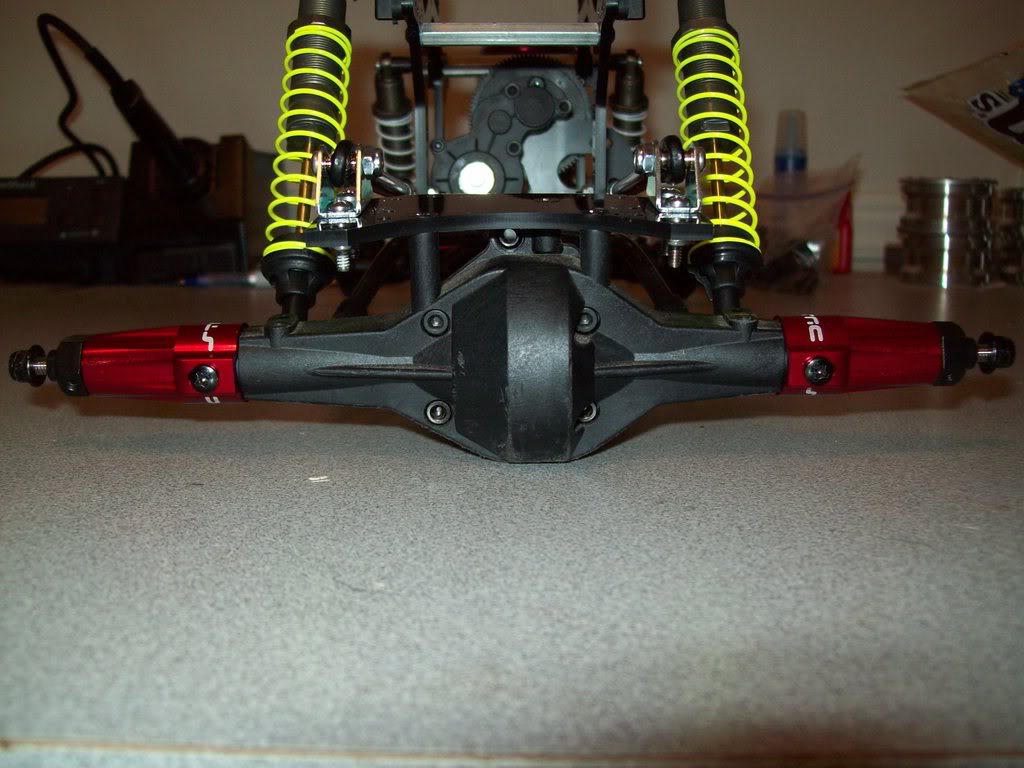

Here's some pics of the truck as I started to work on it. All the plastic axle parts, the upper links were bolted right to the servo plate, and the shocks were attached with phillips head screws, which was only temporary but bothered me a great deal.

First thing, I had ordered some special Tamiya TLT-1 suspension stays (link mounts) to mount the upper links to the servo plates. The way I had them before has worked for some people, but it just didn't seem perfect to me and I don't compromise when it comes to my RC's. So I unbolted the links and mounted the brackets, then installed the upper links to the brackets. You can see how they were bolted on orginally in the pics above, and then compare it with how I mounted them with these brackets. This my friends is what crawling is all about, finding and fabricating parts that work for your situation, which were originally designed for something totally different.

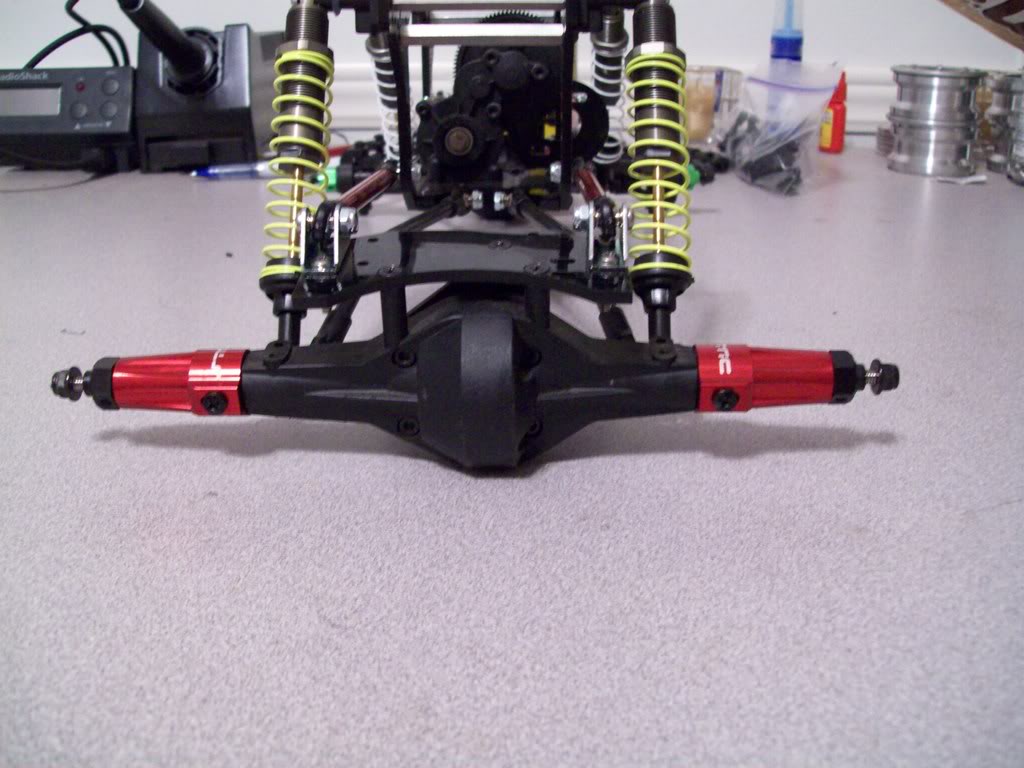

Then I installed the rear lockout. While searching for something I ran across Swetdiesel's article on the dammit wrench. It was perfect timing. I had a bearing that I could not for the life of me get off the axle shaft. I used the dammit wrench a lot, and finally baked the whole assembly at 350 degrees in the oven for about 20 minutes, and it finally came off with some pursuasion. The straight axle conversion provides added stregth and the axles are REALLY beefy (I busted a front axle at the last comp, first time anyone there had actually seen someone that was able to break on lol). They improve ground clearance dramatically, and add a more scale profile. Also, the axials have really bad axle slop from the factory where the axle will slide back and fourth, allowing you to "wiggle" the tire back and fourth when installed. I used a washer inside the STRC lockouts, and completely eliminated that axle wiggle, which made me really happy.

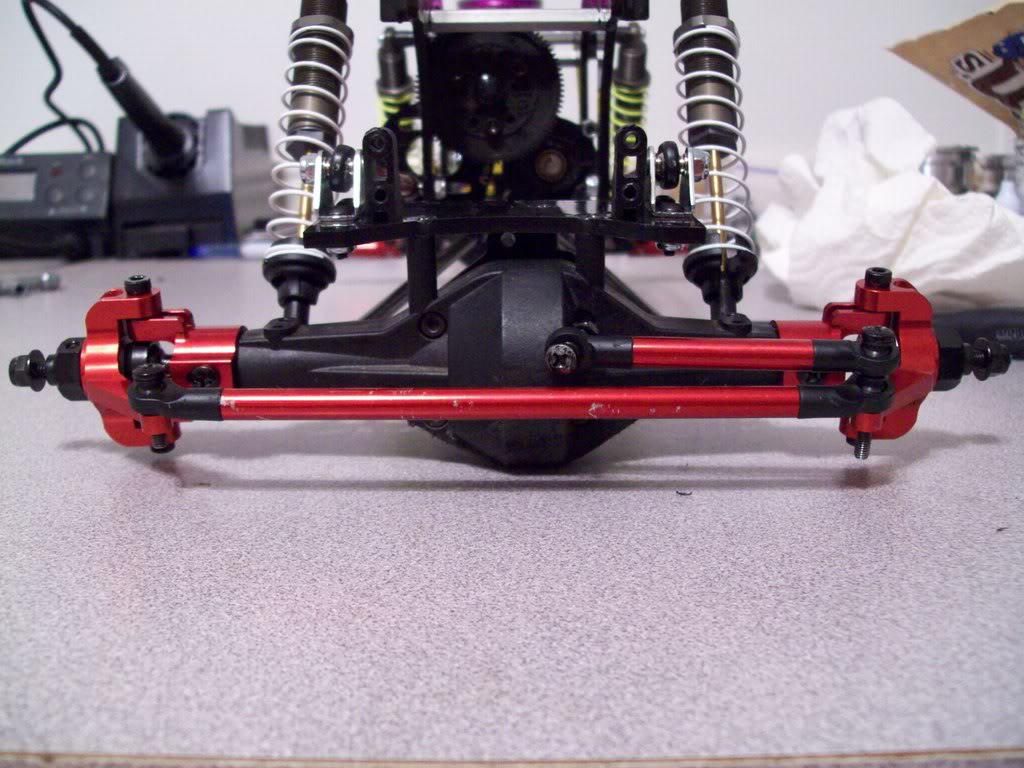

Nex I got started on the front axles. First while I had them apart, I went ahead and installed my brandy new MIP CVD's in the front axle. I only used them in the front because of the straight axle conversion. I went in on halves with another member on the set, so we didn't pay for two that would go to waste. That might be an idea for some of you guys, and it will give you better quality for less money than the axials, even with shipping. After that, I installed the STRC red aluminum knuckles followed by the red aluminum C's. The C's and knuckles are EXCELLENT. They COMPLETELY eliminated the axle wiggle, with no washers or shimming needed. Because of the design, it's going to be REALLY easy to mod these knuckles into high steer knuckles, and with the CVD's, I'm going to have way more steering than most people have with axial axles.

After finishing the axles, I bent the front lower links about 27 degrees to match the rear. This provides tons of ground clearance and puts the wheelbase just under 12.5 inches. Then I replaced the philips head screws that mounted the shocks (they were also too short), with socket head cap screws that were longer which I really needed.

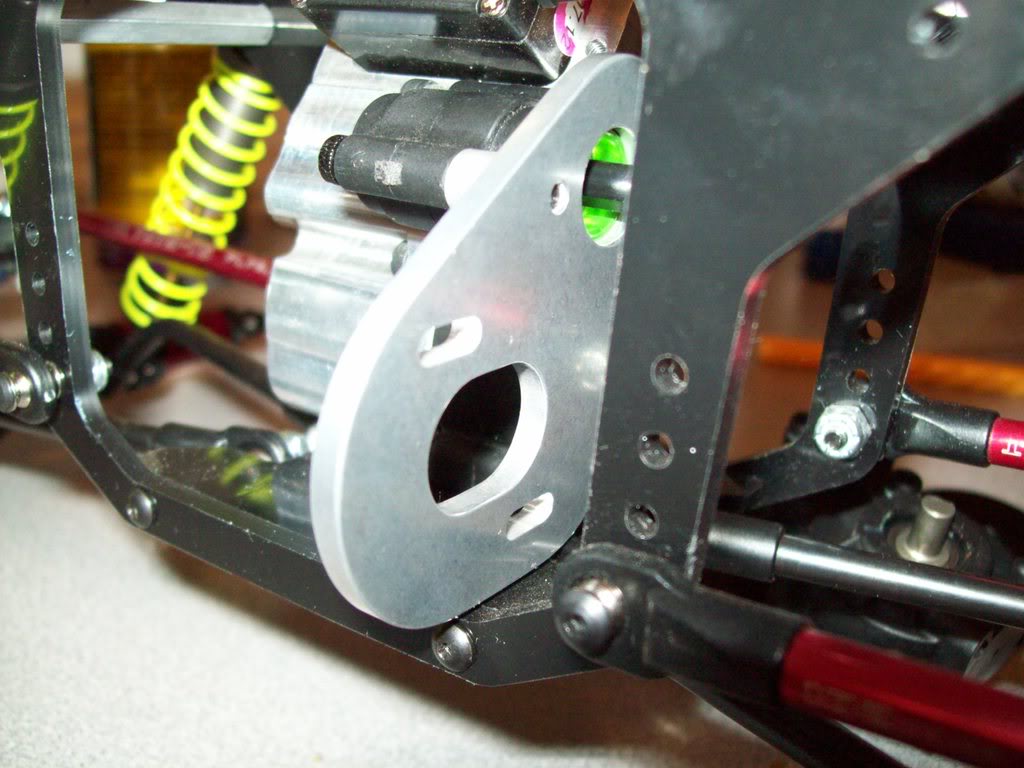

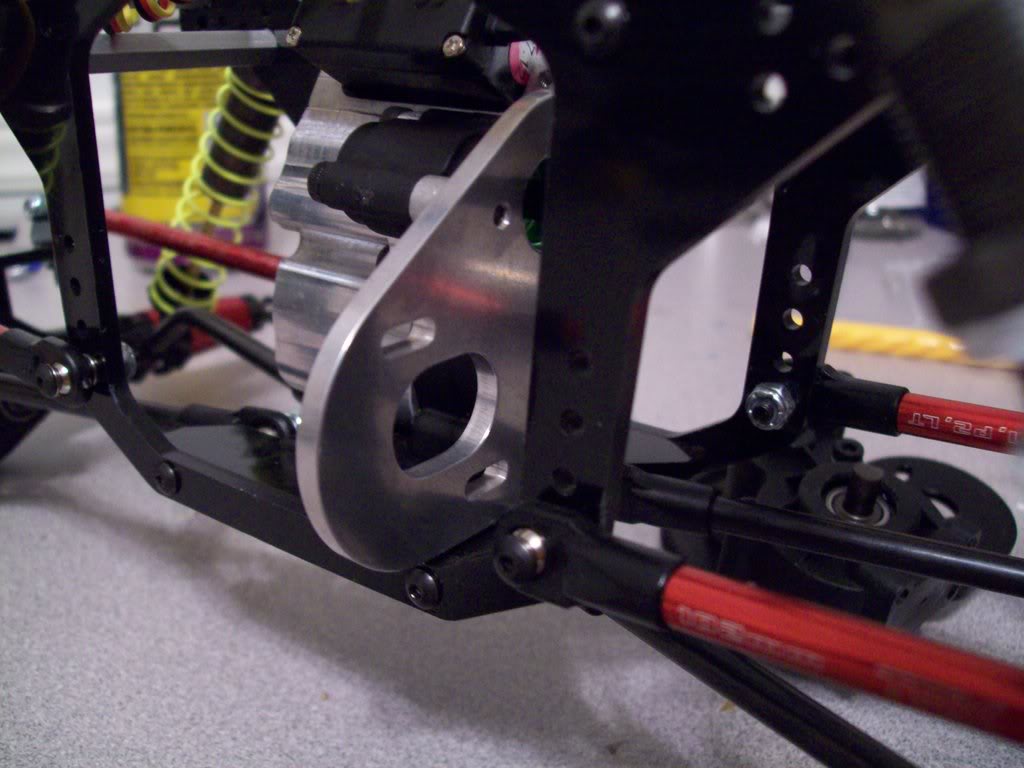

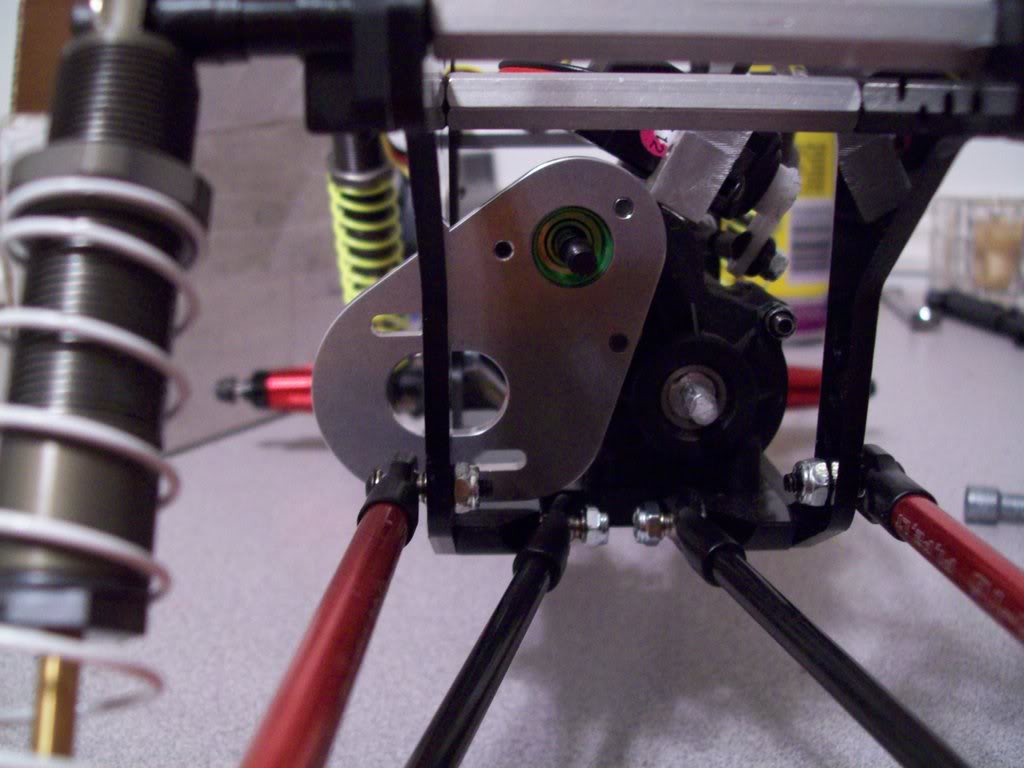

After finishing those two things, it was starting to get late so I decided to install my East End Machining Heavy Duty motor plate and VF dig unit on the Axial tranny, and fit them in the chassis to see how they fit. I will be replacing this dig unit with one of the new black dig units eventually, but this one was already assembled and has been tweaked and tuned to perform perfect. They say the new ones don't need adjusting like the older silver VF style, but only time will tell. WIth the original VF digs, they take just a little adjusting and sanding tolerances and such for smooth, trouble free operation.

I will try to get more done today, and will be posting a complete parts list shortly.

Also, I'm now a sponsored driver for East End Machining. Now you guys know how much I like to drive old beat up RC's put together with bailing wire and duct tape, but when you are a sponsored driver, it's your obligation to have a top of the line rig in tip top shape.

I've gone with a lot of STRC parts for this build, and I'm hooked. I was a little wary of buying from a big name brand company because integy put such a bad taste in my mouth. Boy was I wrong! I absolutely love every STRC part that I've had, and the counts now up to around 15 different parts between all of my rigs. The fit and finish is impeccable, the customer service is excellent, and the parts are absolutely beautiful and perform to the highest standard.

First things first, I had a long day yesterday and didn't get started on the truck until yet, so I guzzled a NOS energy drink, only the best, grape flavored. Breakfast of champions, and lunch and dinner of Charlie!

Here's some pics of the truck as I started to work on it. All the plastic axle parts, the upper links were bolted right to the servo plate, and the shocks were attached with phillips head screws, which was only temporary but bothered me a great deal.

First thing, I had ordered some special Tamiya TLT-1 suspension stays (link mounts) to mount the upper links to the servo plates. The way I had them before has worked for some people, but it just didn't seem perfect to me and I don't compromise when it comes to my RC's. So I unbolted the links and mounted the brackets, then installed the upper links to the brackets. You can see how they were bolted on orginally in the pics above, and then compare it with how I mounted them with these brackets. This my friends is what crawling is all about, finding and fabricating parts that work for your situation, which were originally designed for something totally different.

Then I installed the rear lockout. While searching for something I ran across Swetdiesel's article on the dammit wrench. It was perfect timing. I had a bearing that I could not for the life of me get off the axle shaft. I used the dammit wrench a lot, and finally baked the whole assembly at 350 degrees in the oven for about 20 minutes, and it finally came off with some pursuasion. The straight axle conversion provides added stregth and the axles are REALLY beefy (I busted a front axle at the last comp, first time anyone there had actually seen someone that was able to break on lol). They improve ground clearance dramatically, and add a more scale profile. Also, the axials have really bad axle slop from the factory where the axle will slide back and fourth, allowing you to "wiggle" the tire back and fourth when installed. I used a washer inside the STRC lockouts, and completely eliminated that axle wiggle, which made me really happy.

Nex I got started on the front axles. First while I had them apart, I went ahead and installed my brandy new MIP CVD's in the front axle. I only used them in the front because of the straight axle conversion. I went in on halves with another member on the set, so we didn't pay for two that would go to waste. That might be an idea for some of you guys, and it will give you better quality for less money than the axials, even with shipping. After that, I installed the STRC red aluminum knuckles followed by the red aluminum C's. The C's and knuckles are EXCELLENT. They COMPLETELY eliminated the axle wiggle, with no washers or shimming needed. Because of the design, it's going to be REALLY easy to mod these knuckles into high steer knuckles, and with the CVD's, I'm going to have way more steering than most people have with axial axles.

After finishing the axles, I bent the front lower links about 27 degrees to match the rear. This provides tons of ground clearance and puts the wheelbase just under 12.5 inches. Then I replaced the philips head screws that mounted the shocks (they were also too short), with socket head cap screws that were longer which I really needed.

After finishing those two things, it was starting to get late so I decided to install my East End Machining Heavy Duty motor plate and VF dig unit on the Axial tranny, and fit them in the chassis to see how they fit. I will be replacing this dig unit with one of the new black dig units eventually, but this one was already assembled and has been tweaked and tuned to perform perfect. They say the new ones don't need adjusting like the older silver VF style, but only time will tell. WIth the original VF digs, they take just a little adjusting and sanding tolerances and such for smooth, trouble free operation.

I will try to get more done today, and will be posting a complete parts list shortly.

Last edited: