- Messages

- 5,887

- Reaction score

- 9,728

- Location

- Baltimore

- RC Driving Style

- Bashing

- Racing

- Crawling

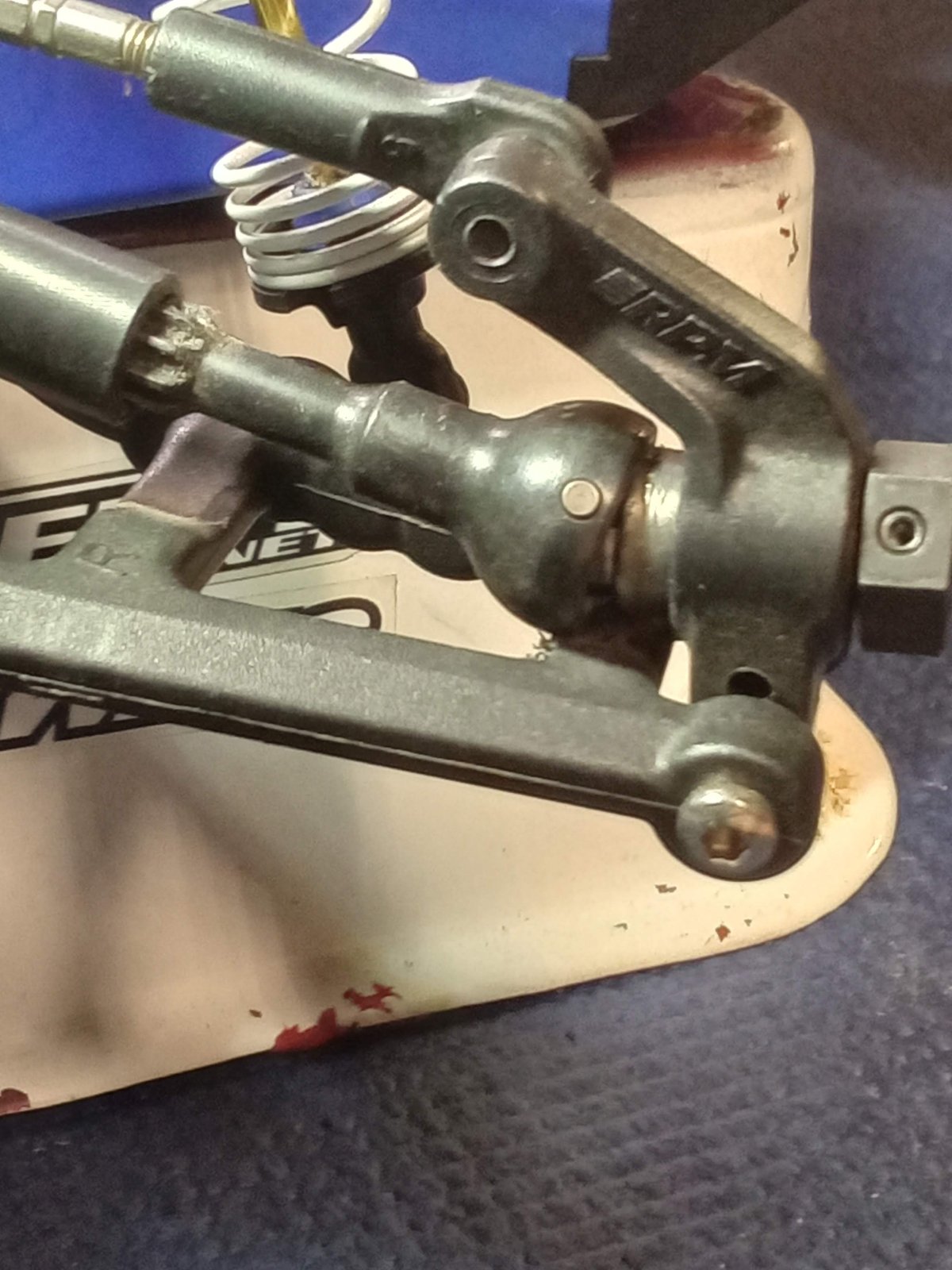

- Scale Builder

So this is the 2nd time i blew a bearing this week. It is the bearing that goes into the rear hub. The first time was last night then the second time was this morning. Could it be the bearings I'm using? Here are the bearings that I am using: Winter Evening - for Traxxas Slash, Stampede, Rustler 2WD 1/10 Bearings Kit (19 Pcs) For the rear hubs I'm using RPM. Also should note I blew the same bearing on the same side. Or it could be the gearing? For the spur I'm using the stock 86t. For the pinion I'm using the optional high speed gearing which is a 23t. What I'm going to try is I'm going to gear down to the stock gearing.(16t pinion) For driveshafts I'm using the MIP X-Duty driveshafts. Everything else in the trans/diff is all stock.