DMC-81

RCTalk Basher

- Thread starter

- #21

Build Process: Step 6

Step 6 involves assembling the Counter Gears and Differential Spur Gear in the Front gearbox.

Here are the Instructions:

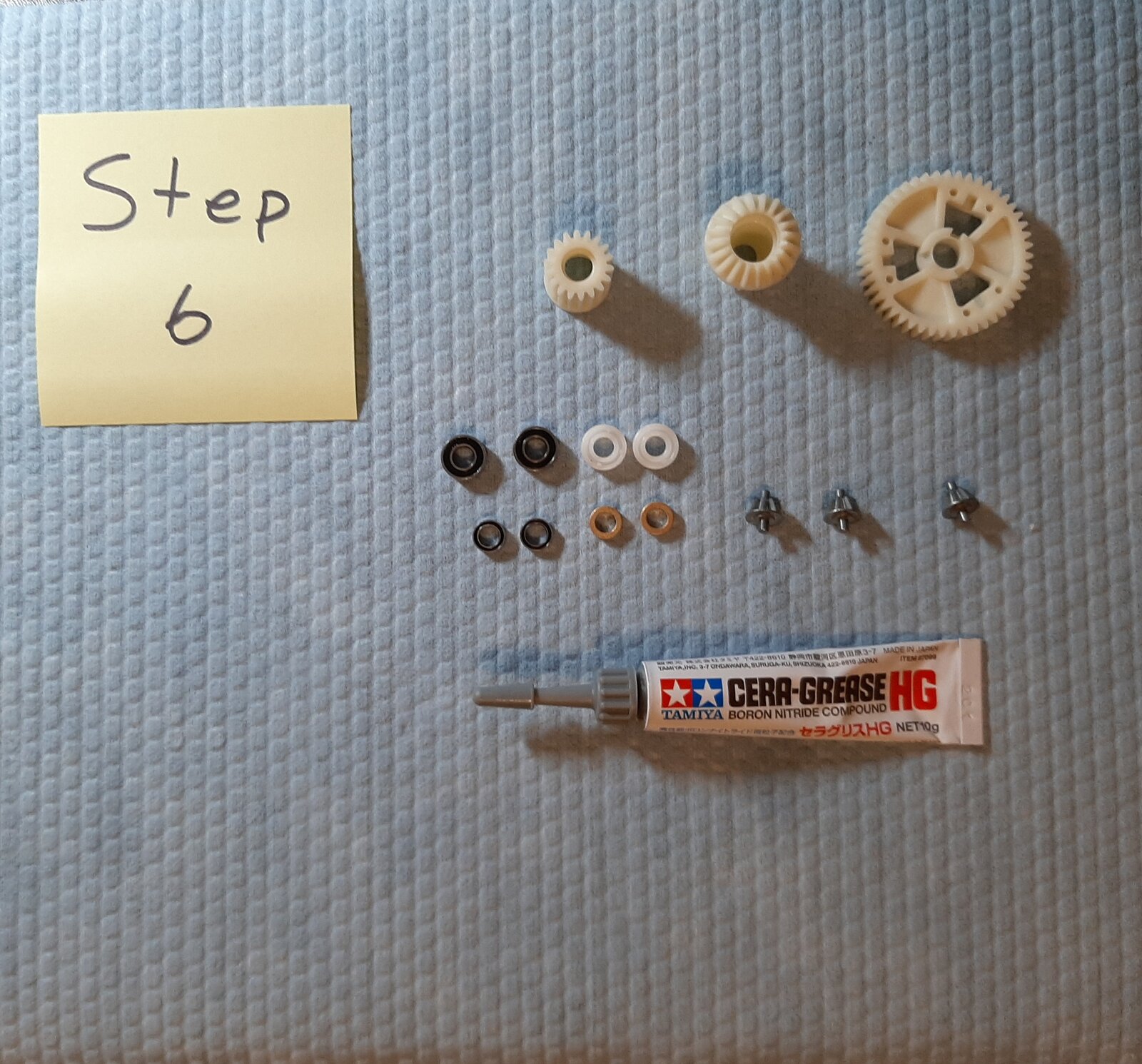

Here are the parts laid out:

Step 6 Commentary:

The Fast Eddy sealed ball bearings are on the left side and the original Tamiya plastic and brass bushings are on the right side. As before, I chose the sealed ball bearings. I remember the super-fast performance of this little buggy at the time in 1985 so I can’t wait to see what a full set of ball bearings and the optional motors will do:

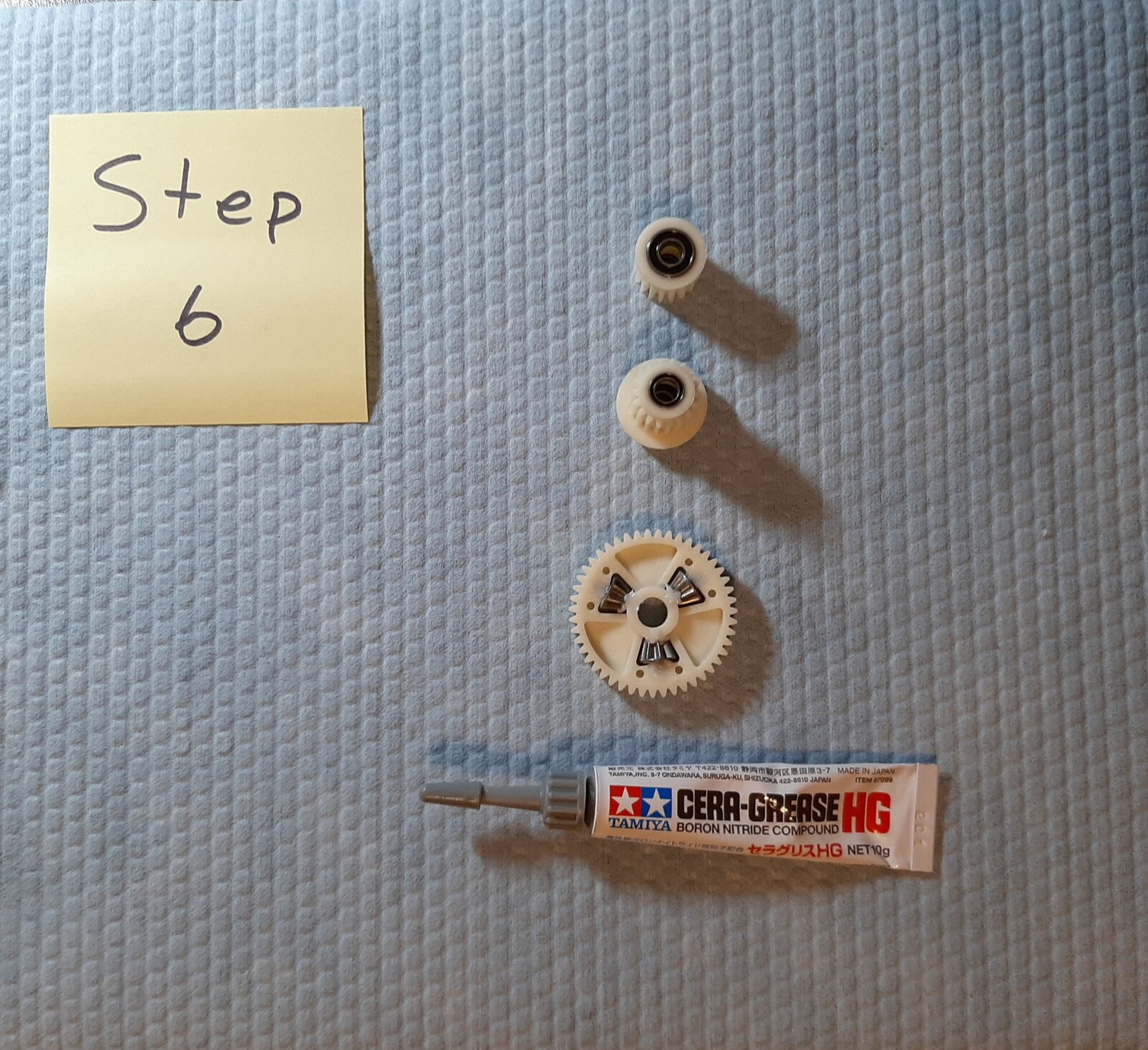

Here are the gears assembled. I added more grease in a later step:

Step 6 involves assembling the Counter Gears and Differential Spur Gear in the Front gearbox.

Here are the Instructions:

Here are the parts laid out:

Step 6 Commentary:

The Fast Eddy sealed ball bearings are on the left side and the original Tamiya plastic and brass bushings are on the right side. As before, I chose the sealed ball bearings. I remember the super-fast performance of this little buggy at the time in 1985 so I can’t wait to see what a full set of ball bearings and the optional motors will do:

Here are the gears assembled. I added more grease in a later step: