WickedFog

Starter of too many projects

Supporter

Excellence Award

Hospitality Award

Rig of the Month Winner

Build Thread Contributor

- Messages

- 14,818

- Reaction score

- 20,923

- Location

- Terre Haute, IN

- RC Driving Style

- Bashing

- Crawling

- Scale Builder

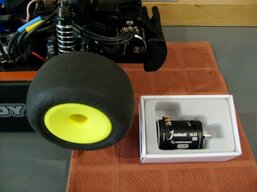

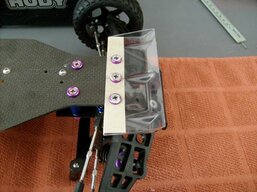

Lol. That's funny. I wish I had gotten into RC drag racing a long time ago. Never thought I would enjoy it so much.Thanks, Kevin. Chassis is veteran of two seasons bracket class in RC drag racing, '05-'06. Placed 21st in national standings 2006. Brought her out of retirement for this project.

Staging opposite one of my frequent competitors back then, he said "I'm gonna build a slow car like yours so I can always leave first. . ." I just grinned and then took the win light (again). HeHe. Fun times. 'AC'