So my v14.6 is showing signs that its comeing to the end of its life witch sucks ass really bad as we do get attached to these things lol but fear not my dudes i have been repinching these cylinders for a while now and it works really well .you get a lot more runtime before the symptoms come back so i would recommend trying it for all you need to achieve it cost's very little .

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

More options

Who Replied?Deku

RCTalk Basher

wait what.. what type of bracket in the workbench clamp is that ? could you perhaps point me to a link of some sorts ? or more info

cbaker65

RCTalk VIP

So my v14.6 is showing signs that its comeing to the end of its life witch sucks ass really bad as we do get attached to these things lol but fear not my dudes i have been repinching these cylinders for a while now and it works really well .you get a lot more runtime before the symptoms come back so i would recommend trying it for all you need to achieve it cost's very little .

If you can figure out how to squeeze that all a way around the sleeve evenly you can put back some of

the pinch for some more run time ,looks like you found away ,use to be able to buy the pinch tooling ,

I missed out on some years ago when they were on E-bay!..

- Thread starter

- #4

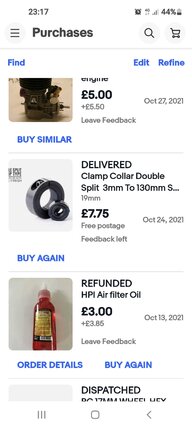

Yea bro iv got the tools they still sell them mate all different broes .these cheep clamps do the same job its the copper ring that goes inside the tool that dose the real work

22mm clamps bro 22mm copper cut into a 5mm wide ring as u only want to clamp the top 5mm of the cylinder and a table top clamp heat your cylinder to 100c clamp and quench in cold water test with piston and repeatedly do this till u get a good pinchwait what.. what type of bracket in the workbench clamp is that ? could you perhaps point me to a link of some sorts ? or more info

Attachments

Maximum_Quake_Pro.com

RCTalk Addict

Key points I've learned;

Breathe just barely tighten it , overdo and you ruined it.

Make sure the pressure is applied evenly and piston at TDC otherwise you most likely will make sleeve a bit ovaled

Be sure to check rod bushing slop every time you Repinch. Extra stress from the increased compression on a worn rod bushing or crank pin will end badly.

Breathe just barely tighten it , overdo and you ruined it.

Make sure the pressure is applied evenly and piston at TDC otherwise you most likely will make sleeve a bit ovaled

Be sure to check rod bushing slop every time you Repinch. Extra stress from the increased compression on a worn rod bushing or crank pin will end badly.

Deku

RCTalk Basher

i have found the magic squeezing ring in my country.

Good info on re-pinching and doing it in baby steps!

i have an old gs? .15 engine i can test this on and get a feel for it.

its a parts engine anyways and the sleeve is shot no matter what, piston falls right through

Good info on re-pinching and doing it in baby steps!

i have an old gs? .15 engine i can test this on and get a feel for it.

its a parts engine anyways and the sleeve is shot no matter what, piston falls right through

Maximum_Quake_Pro.com

RCTalk Addict

I'm a gs racing freak. Former sponsored driver and still have my storms and run them.i have found the magic squeezing ring in my country.

Good info on re-pinching and doing it in baby steps!

i have an old gs? .15 engine i can test this on and get a feel for it.

its a parts engine anyways and the sleeve is shot no matter what, piston falls right through

If its a black head gs .15 its the same internally as the mach .15 black head from a losi

Deku

RCTalk Basher

It's not a gs sadly, i just took it out of my benched engine closet because i wanted to know for sureI'm a gs racing freak. Former sponsored driver and still have my storms and run them.

If its a black head gs .15 its the same internally as the mach .15 black head from a losi

i discovered it says "Team Orion" on the side of the block which is also marked on top of the grey/silver head.

but i cannot for the life of me find the engine size number anywhere on the block. the block looks smaller then a .15 but the head doesn't..

EDIT: so i just found out it is a .12 and probably made between 2001 and whenever. it used to power my RS4 back in the day

Maximum_Quake_Pro.com

RCTalk Addict

Oooh one of my favorites id love to have her if completeIt's not a gs sadly, i just took it out of my benched engine closet because i wanted to know for sure

i discovered it says "Team Orion" on the side of the block which is also marked on top of the grey/silver head.

but i cannot for the life of me find the engine size number anywhere on the block. the block looks smaller then a .15 but the head doesn't..

EDIT: so i just found out it is a .12 and probably made between 2001 and whenever. it used to power my RS4 back in the day

- Thread starter

- #10

If you over titen it u can just reheat and push the piston back in to open her back up mateKey points I've learned;

Breathe just barely tighten it , overdo and you ruined it.

Make sure the pressure is applied evenly and piston at TDC otherwise you most likely will make sleeve a bit ovaled

Be sure to check rod bushing slop every time you Repinch. Extra stress from the increased compression on a worn rod bushing or crank pin will end badly.

Maximum_Quake_Pro.com

RCTalk Addict

Meant to say thanks for sharing your methodYea bro iv got the tools they still sell them mate all different broes .these cheep clamps do the same job its the copper ring that goes inside the tool that dose the real work

22mm clamps bro 22mm copper cut into a 5mm wide ring as u only want to clamp the top 5mm of the cylinder and a table top clamp heat your cylinder to 100c clamp and quench in cold water test with piston and repeatedly do this till u get a good pinch

- Thread starter

- #12

No problem at all mateMeant to say thanks for sharing your method