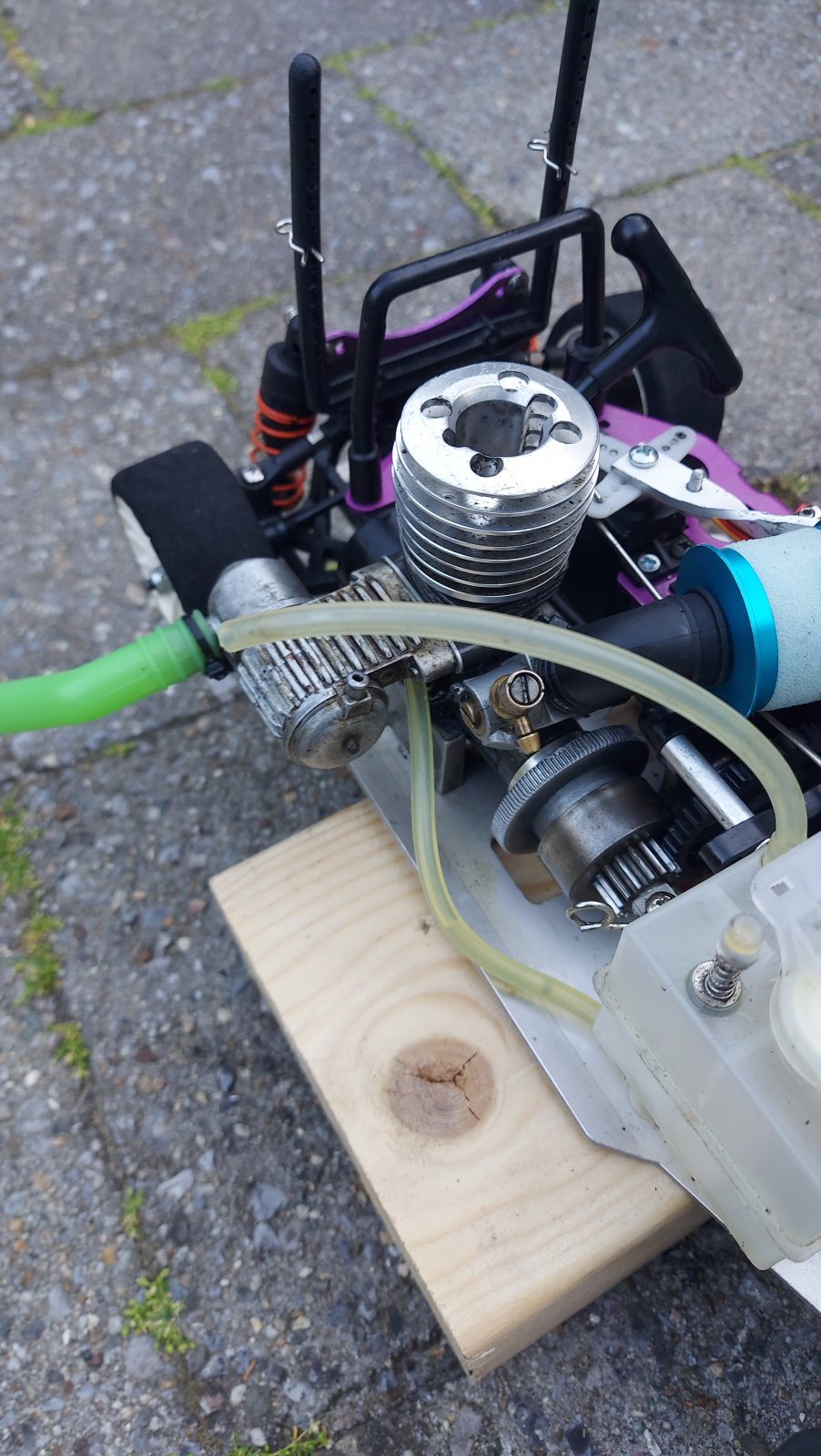

Hello, today I've put in and set all the electronics to my new RC. I confirmed the engine started for 4 seconds but that's it. Guess what? My fourth carb with a problem. They must hate me. Here some pics:

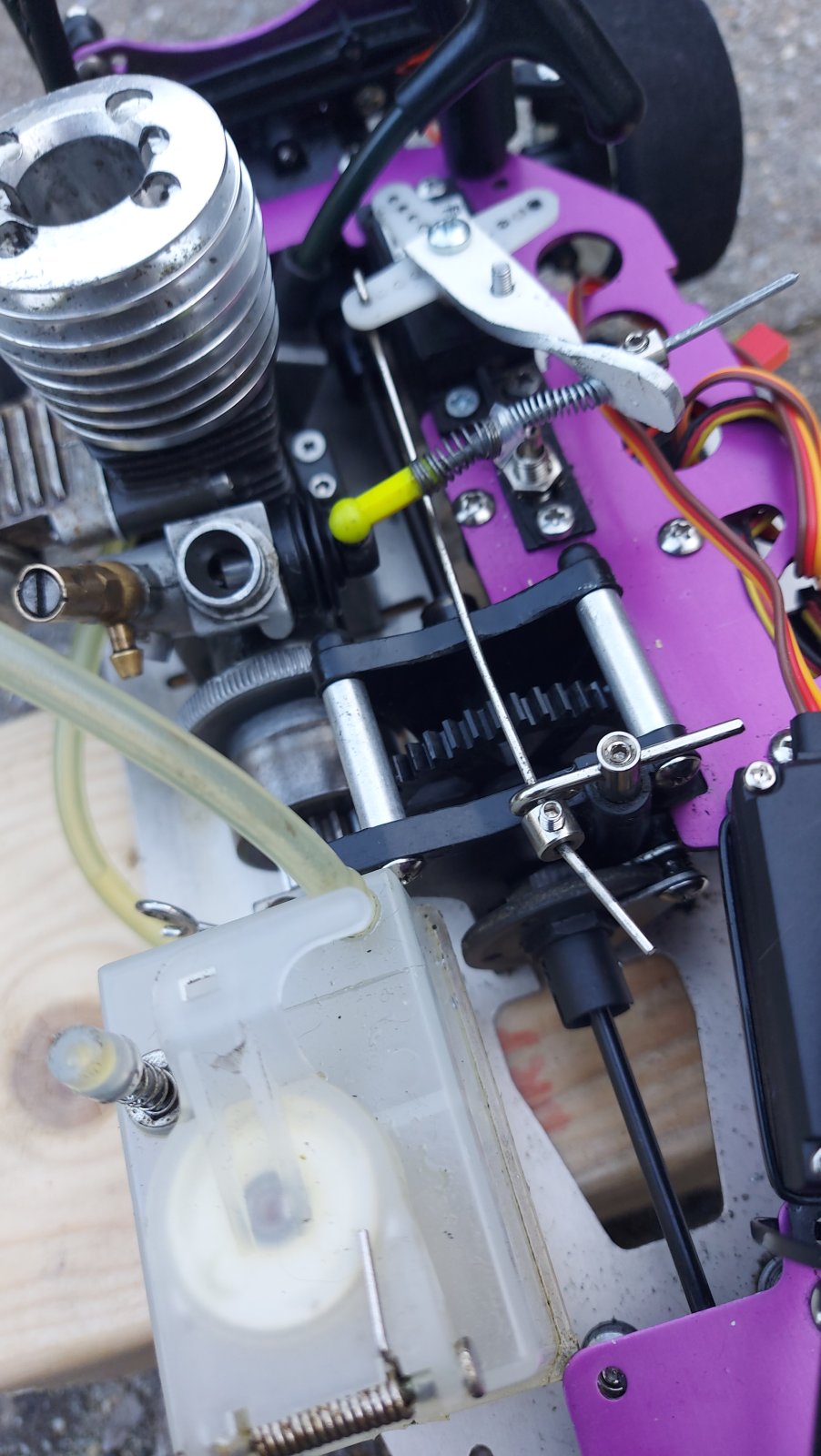

I know I know, the throttle setup is awesome, but please help. Is there a cheap replacement carb? If there is any way to repair this massive crack in the old carb please tell me.

I know I know, the throttle setup is awesome, but please help. Is there a cheap replacement carb? If there is any way to repair this massive crack in the old carb please tell me.

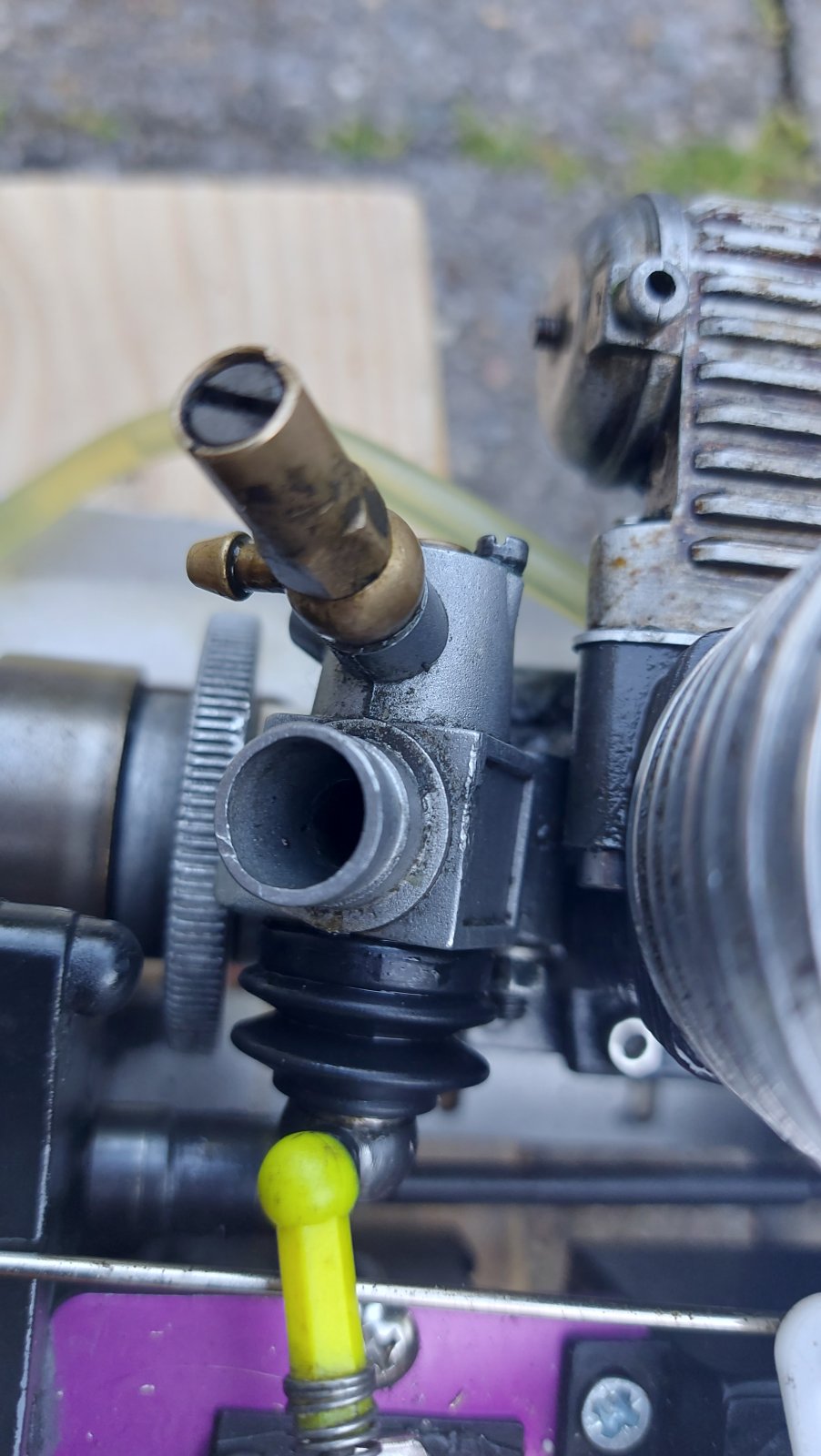

This crack was already there before I bought it. But when I screwed it in, which didn't even need any force, it broke even further.

Total diameter of the carb where airfilter is hooked up: 11mm

Total diameter of the other side of the carb that goes into the engine:i guess 10mm(hard time measuring due to crack)

I'm talking about the diameter of the whole, not the hole

This crack was already there before I bought it. But when I screwed it in, which didn't even need any force, it broke even further.

Total diameter of the carb where airfilter is hooked up: 11mm

Total diameter of the other side of the carb that goes into the engine:i guess 10mm(hard time measuring due to crack)

I'm talking about the diameter of the whole, not the hole