- Thread starter

- #21

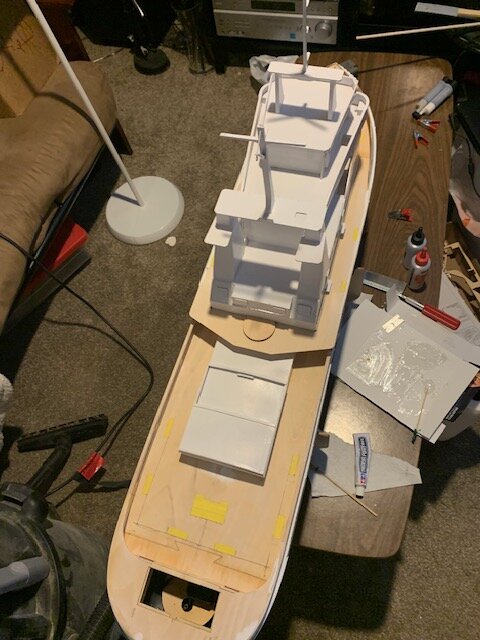

Well back to the build, summer and harvest got in the way was a busy one.

Managed to squeeze in a few days of painting on and off.

Now working on the finish of the rigging.

Will be ready for maiden come spring.

Couple closer shots of the cable guard rails.

Braided cable is run through thin metal uprights , a slow process but adds to the finish look.

Managed to squeeze in a few days of painting on and off.

Now working on the finish of the rigging.

Will be ready for maiden come spring.

Couple closer shots of the cable guard rails.

Braided cable is run through thin metal uprights , a slow process but adds to the finish look.