Electric RCs can be confusing especially for people that are newer to the hobby and, some aspects of electrics can be confusing even to RC veterans, so I thought Id take a few minutes and explain some things that tends to trip people up. This post is going to attempt to explain what "Turns", "Winds", "kV", and "Poles" are in DC motors.

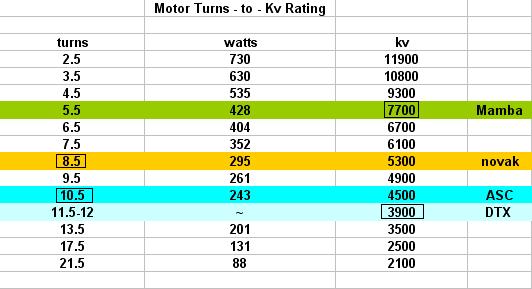

One thing that I see all the time is people confused about the difference between turns and kV. They both are an indication of how fast and/or torque"y" the motor is but theres no direct way of comparing one to the other. The only thing we can do is look up a chart or do some math to come up with an approximation. Most, if not all, of the Turns to kV charts I've found on the internet seem to all be based on a chart that was created by RC Car Action. Ill post their chart below. As far as I can tell, RCCA's chart was based on tests done on 4 different motors (The motors that are highlighted) and the rest were extrapolated from those four results. Someone correct me if I'm wrong about this.

I have also found this formula for approximating kV to turns that was based directly on this chart. Using this formula, as noted below, the approximations get less accurate as you get closer to the extremes. (either really high or really low turn motors).

kV rating is (as most people generally know) is how many RPMs a motor will spin per volt applied to it. For example a 2000kV motor will spin 2000RPM per volt of electricity applied to it. So if you give it 10V it will spin at 20,000RPM.

Turns, on the other hand, are how many times the copper wire inside the motor wraps around each armature of the motor. "kV" is kinda like HP in an engine and "Turns" has more to do with how the engine was built. This is why there is no direct correlation between turns and kV and it can only be approximated.

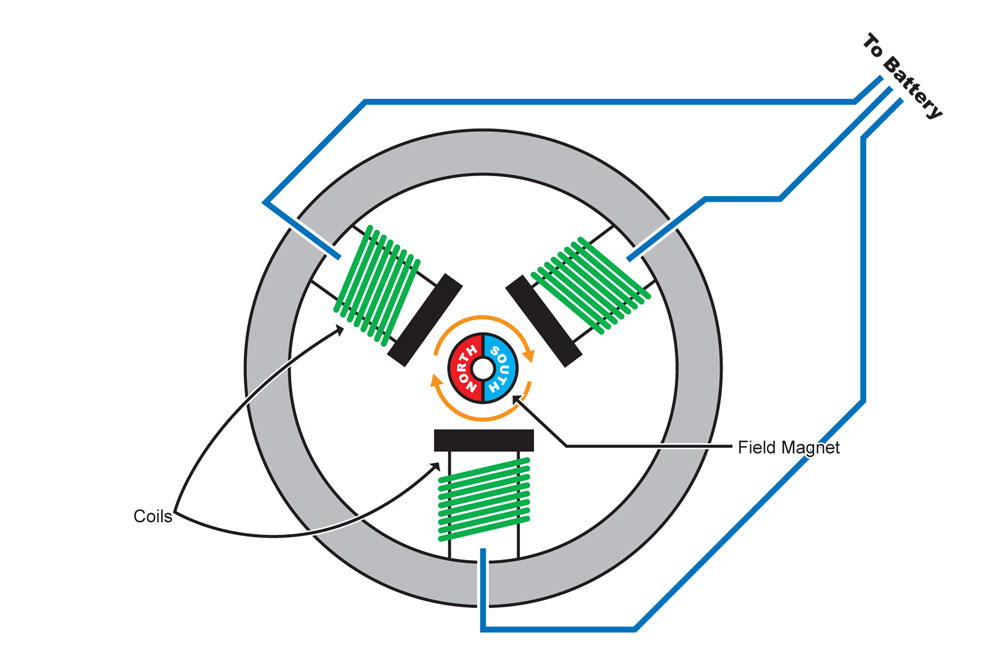

*NOTE* In the pic below where it says "To Battery" it really should say "To Speed Controller"

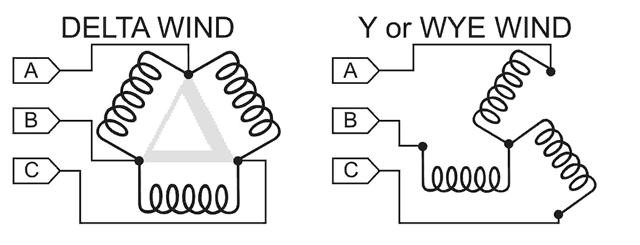

Then there are winds which are different than turns. Youve probably seen on some motors, like Castle Creations motors, Wye and Delta wind types listed. For example we all know the famous Castle 1515 2200kV and if you look at the can it will say 1515/1Y 2200kV on the can. The 1Y tells us that this motor has a 1 Wye wind. What is a wind? I can't say I fully understand everything there is to know about winds but what I do know is the basics. So in the previous paragraph we talked about how a 12T motor has the copper wire wrapped around each armature 12 times. The wind rating is actually a rating signifying two different things. Lets use 12T/1Y as an example. The 12T tells us that the copper wire is wrapped around each armature 12 times. The 1 in 1Y tells us that there is only 1 stand of copper being wound around each of the armatures 12 times. Wye and Delta just signifies the pattern in which the wire is wrapped and terminated before exiting the can to go to the ESC. So if we had a 12T/4D motor then each armature has 4 pieces of wire wrapped around it 12 times in the delta pattern. The pic below will give you a better idea of the difference between a wye and delta wind.

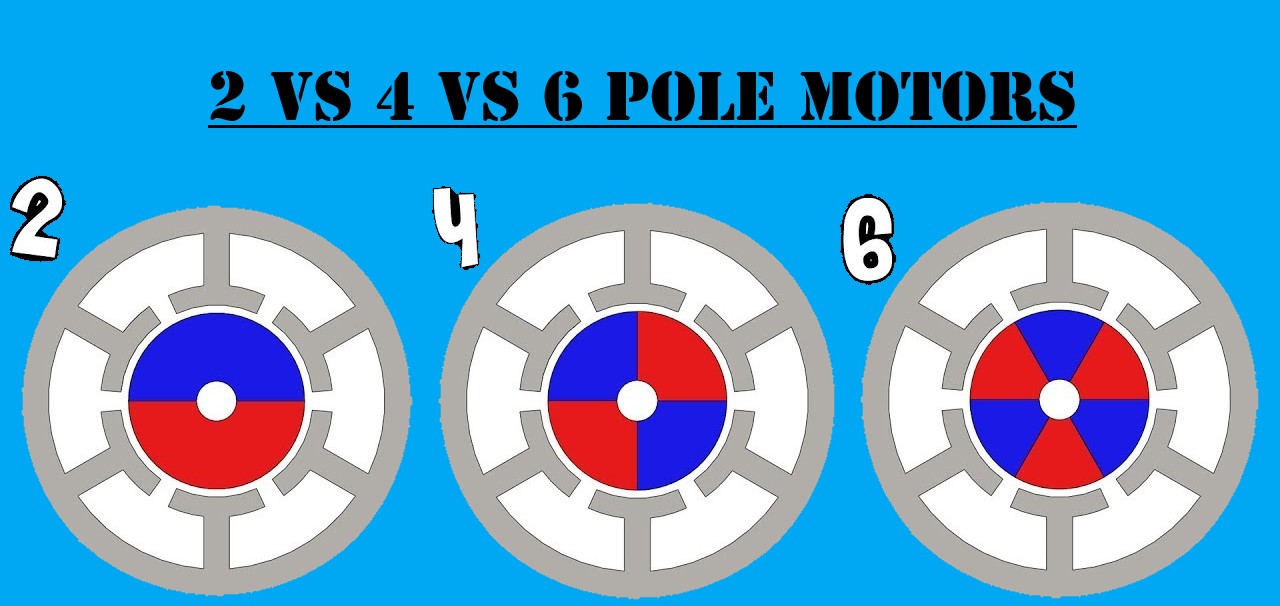

As for poles this has to do with the number of magnetic "poles" inside the motor. A 2pole motor only has two magnets or "poles", a 4 pole has 4, etc etc. The poles or magnets are what is mounted to the "rotor" which is the piece that is essentially the shaft sticking out of the motor. The armatures that have the copper wire wrapped around them are called stators. The more poles the more torque but it also means less RPMs at least generally speaking. Sometimes, there are ways an engineer can make up for a motor having more or less torque/RPMs based on the type of winds used for a given turn rating but I'm not even going to go down that rabbit hole.

I already hear you asking "how can we tell how many poles a motor has?". Well the only sure fire 100% way is to take it apart and visually inspect it (or look at the motors specs) but the vast majority of the time motors that are listed in turns are 2 pole and motors listed with a kV rating are 4 (or more) poles. There are exceptions to this but most of the time this is going to be true at least from what I've read. One other possible way to tell a 2 pole motor from a 4 pole motor is to take a magnet and while holding the rotor still and get the magnet close enough to the motor to feel the push and pull of the poles (you want to keep the magnet off of the motor though) and slowly run it around the motor counting how many times you feel the poles change in one revolution.

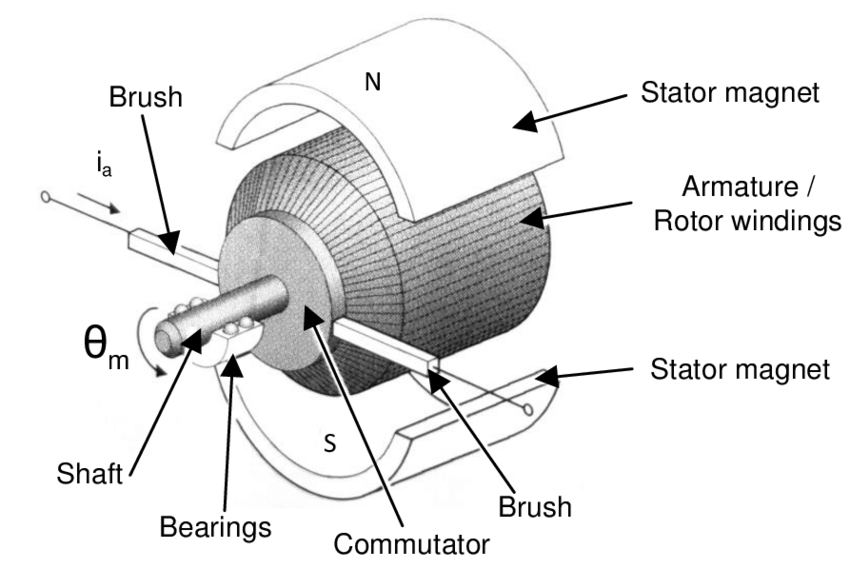

Incidentally if you didnt know this already, brushed motors also have stators and rotors too but the copper wire is wound around the rotor instead of the stator and the magnets are placed on the stator, which in the case of a brushed motor, the stator is basically the entire inside of the can. This is why brushed motors have to have brushes. Since you can't hook wires up directly to a spinning rotor the brushes take the electricity from the wires and transfer it to the rotor. The brushes are pushed against a section of the rotor called the commutator by springs so that they keep in constant contact with it. This is how the turns of copper wire are powered when they are attached to the rotor.

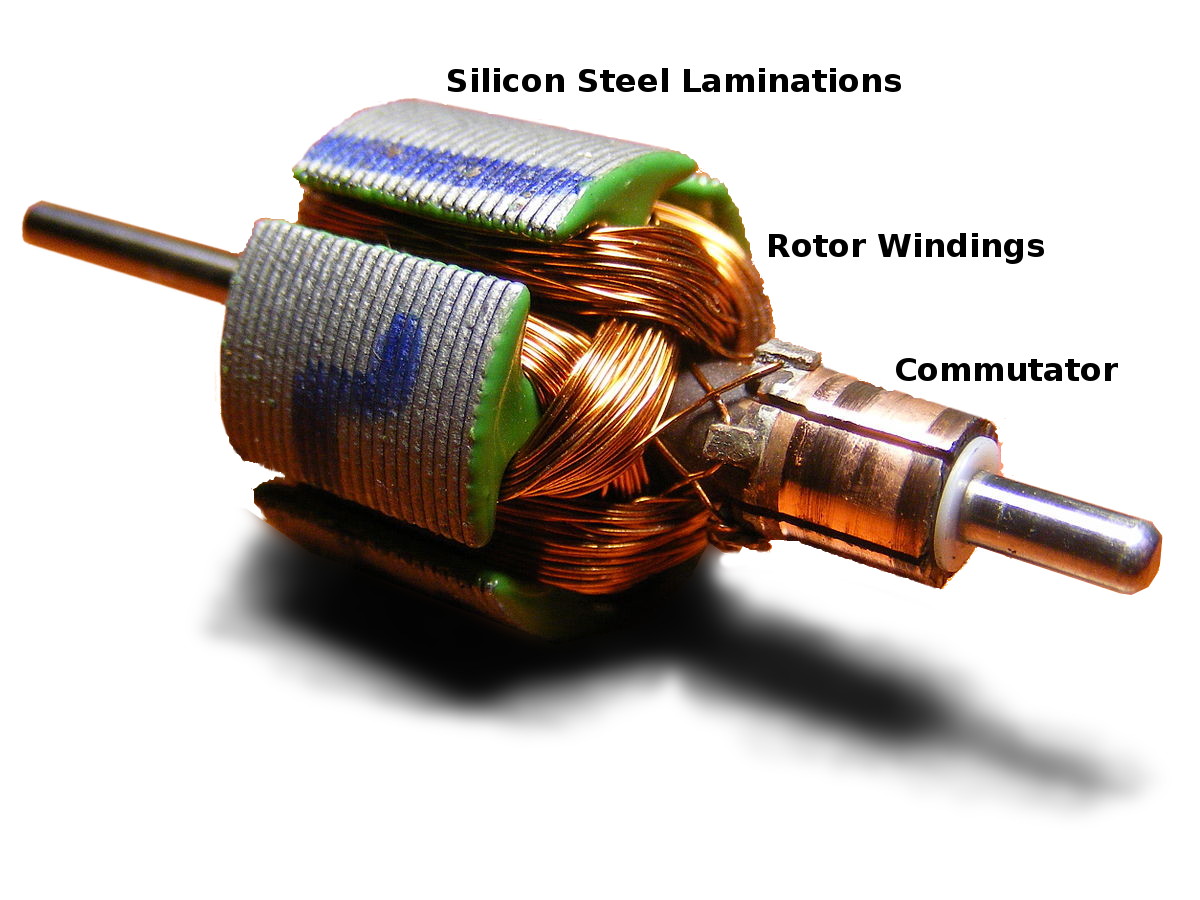

This pic here shows the wear spots from where the brushes were in contact with the commutator while it was spinning. The separations in the commutator are how the rotor activates each section of windings. That way only the section that is in contact with the brushes is active and thats what allows it to "chase" the magnets around and spin.

This is probably waaaaay more in depth than anyone wanted to know but i hope that clears up some of the confusion around turns, winds, kV and poles.

One thing that I see all the time is people confused about the difference between turns and kV. They both are an indication of how fast and/or torque"y" the motor is but theres no direct way of comparing one to the other. The only thing we can do is look up a chart or do some math to come up with an approximation. Most, if not all, of the Turns to kV charts I've found on the internet seem to all be based on a chart that was created by RC Car Action. Ill post their chart below. As far as I can tell, RCCA's chart was based on tests done on 4 different motors (The motors that are highlighted) and the rest were extrapolated from those four results. Someone correct me if I'm wrong about this.

I have also found this formula for approximating kV to turns that was based directly on this chart. Using this formula, as noted below, the approximations get less accurate as you get closer to the extremes. (either really high or really low turn motors).

kV rating is (as most people generally know) is how many RPMs a motor will spin per volt applied to it. For example a 2000kV motor will spin 2000RPM per volt of electricity applied to it. So if you give it 10V it will spin at 20,000RPM.

Turns, on the other hand, are how many times the copper wire inside the motor wraps around each armature of the motor. "kV" is kinda like HP in an engine and "Turns" has more to do with how the engine was built. This is why there is no direct correlation between turns and kV and it can only be approximated.

*NOTE* In the pic below where it says "To Battery" it really should say "To Speed Controller"

Then there are winds which are different than turns. Youve probably seen on some motors, like Castle Creations motors, Wye and Delta wind types listed. For example we all know the famous Castle 1515 2200kV and if you look at the can it will say 1515/1Y 2200kV on the can. The 1Y tells us that this motor has a 1 Wye wind. What is a wind? I can't say I fully understand everything there is to know about winds but what I do know is the basics. So in the previous paragraph we talked about how a 12T motor has the copper wire wrapped around each armature 12 times. The wind rating is actually a rating signifying two different things. Lets use 12T/1Y as an example. The 12T tells us that the copper wire is wrapped around each armature 12 times. The 1 in 1Y tells us that there is only 1 stand of copper being wound around each of the armatures 12 times. Wye and Delta just signifies the pattern in which the wire is wrapped and terminated before exiting the can to go to the ESC. So if we had a 12T/4D motor then each armature has 4 pieces of wire wrapped around it 12 times in the delta pattern. The pic below will give you a better idea of the difference between a wye and delta wind.

As for poles this has to do with the number of magnetic "poles" inside the motor. A 2pole motor only has two magnets or "poles", a 4 pole has 4, etc etc. The poles or magnets are what is mounted to the "rotor" which is the piece that is essentially the shaft sticking out of the motor. The armatures that have the copper wire wrapped around them are called stators. The more poles the more torque but it also means less RPMs at least generally speaking. Sometimes, there are ways an engineer can make up for a motor having more or less torque/RPMs based on the type of winds used for a given turn rating but I'm not even going to go down that rabbit hole.

I already hear you asking "how can we tell how many poles a motor has?". Well the only sure fire 100% way is to take it apart and visually inspect it (or look at the motors specs) but the vast majority of the time motors that are listed in turns are 2 pole and motors listed with a kV rating are 4 (or more) poles. There are exceptions to this but most of the time this is going to be true at least from what I've read. One other possible way to tell a 2 pole motor from a 4 pole motor is to take a magnet and while holding the rotor still and get the magnet close enough to the motor to feel the push and pull of the poles (you want to keep the magnet off of the motor though) and slowly run it around the motor counting how many times you feel the poles change in one revolution.

Incidentally if you didnt know this already, brushed motors also have stators and rotors too but the copper wire is wound around the rotor instead of the stator and the magnets are placed on the stator, which in the case of a brushed motor, the stator is basically the entire inside of the can. This is why brushed motors have to have brushes. Since you can't hook wires up directly to a spinning rotor the brushes take the electricity from the wires and transfer it to the rotor. The brushes are pushed against a section of the rotor called the commutator by springs so that they keep in constant contact with it. This is how the turns of copper wire are powered when they are attached to the rotor.

This pic here shows the wear spots from where the brushes were in contact with the commutator while it was spinning. The separations in the commutator are how the rotor activates each section of windings. That way only the section that is in contact with the brushes is active and thats what allows it to "chase" the magnets around and spin.

This is probably waaaaay more in depth than anyone wanted to know but i hope that clears up some of the confusion around turns, winds, kV and poles.

Last edited: