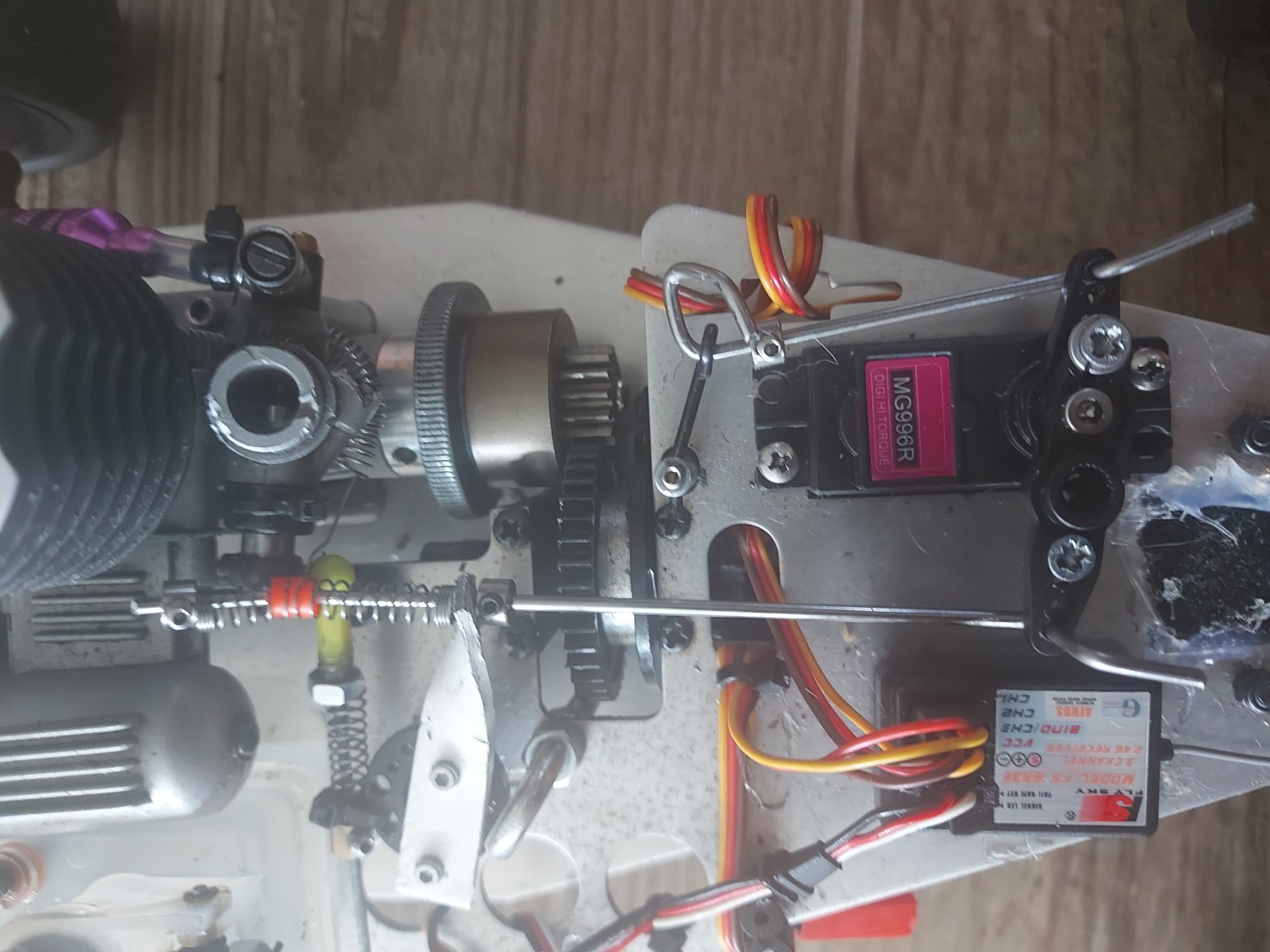

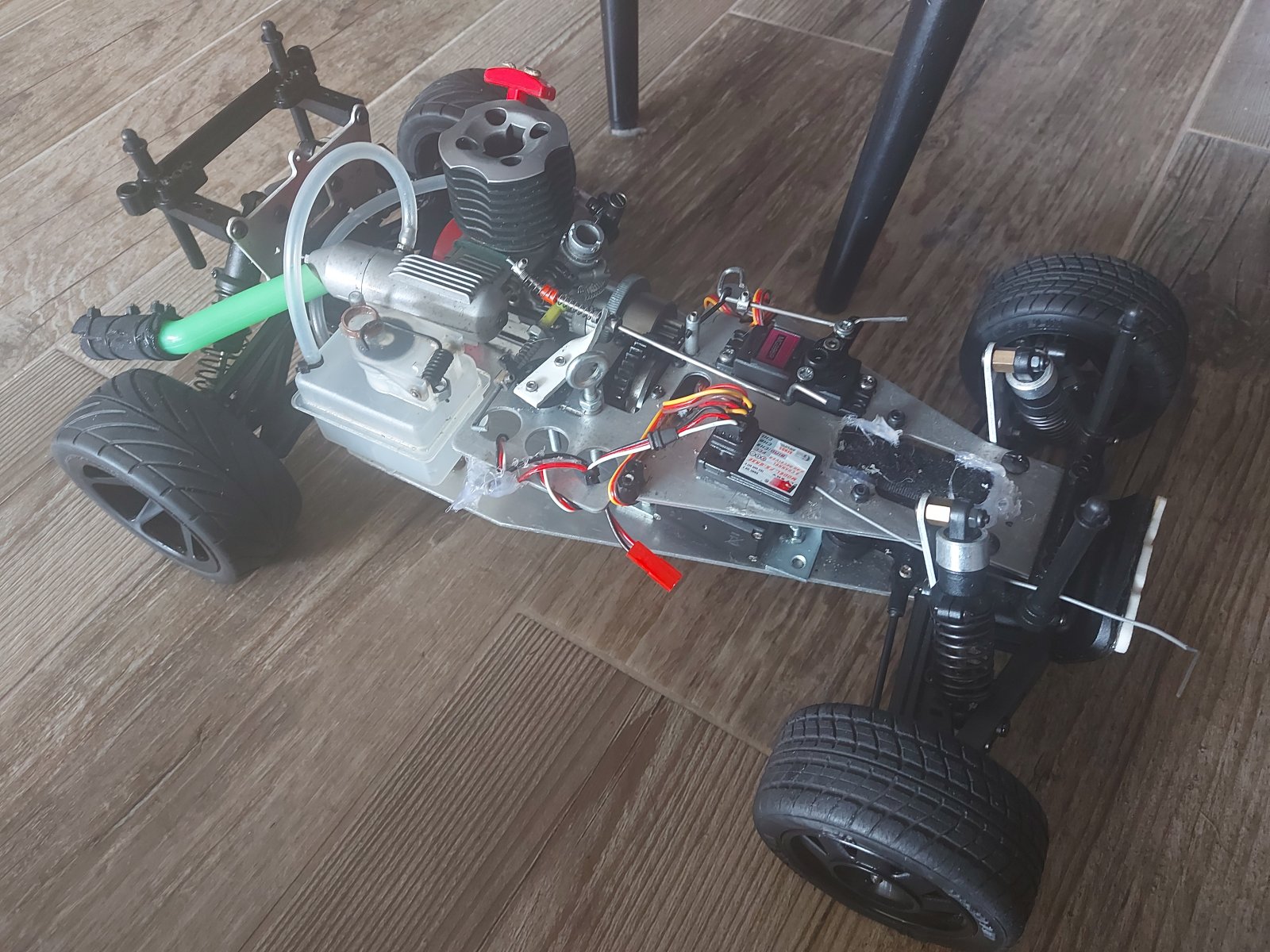

Hello just finished working on this "T2M serie 5000". After buying a second engine, because the first one started leaking from bearings, the newer one leaked too So this is the 3rd engine: a "CEN NT16". Looks kinda overpowered for this car... might switch to a bigger clutchbell sooner or later. The idea was to put this NT16 in my new project, the "Carson Dazzler", but there is no space in that car in order to switch to a slidecarb. So I ended up putting it in the T2M, I had to improvise a lot but atleast there was the space for it

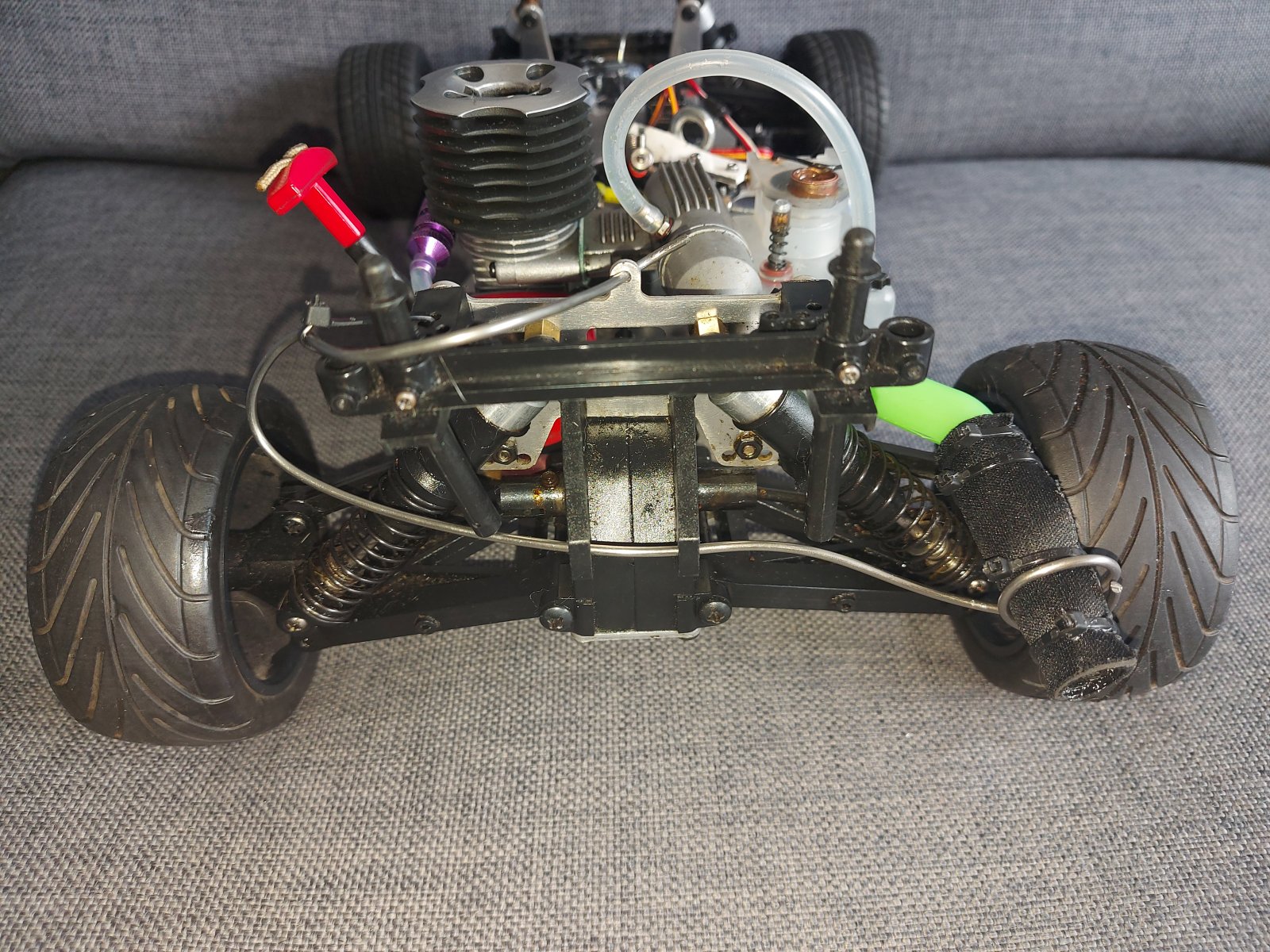

So this is the 3rd engine: a "CEN NT16". Looks kinda overpowered for this car... might switch to a bigger clutchbell sooner or later. The idea was to put this NT16 in my new project, the "Carson Dazzler", but there is no space in that car in order to switch to a slidecarb. So I ended up putting it in the T2M, I had to improvise a lot but atleast there was the space for it . Love the way things worked out, especially the rear exhaust! I'll make a hole for it in the body

. Love the way things worked out, especially the rear exhaust! I'll make a hole for it in the body

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

links, including eBay, Amazon, and others.

More options

Who Replied?- Thread starter

- #2

I just bent a 2mm metal rod and more or less made a "exhaust holder" from it. It was really wobbly

STONER RC

BUILD it, SEND it, BASH it, FIX it, REPEAT

Lifetime Supporter!

Supporter

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 4,429

- Reaction score

- 3,862

- Location

- Brick, New Jersey

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

- Flying

- Boating

Hell yeah man good job. Bet she rips. Smart thinking...I just bent a 2mm metal rod and more or less made a "exhaust holder" from it. It was really wobblyView attachment 170139

Nice work. I love working on them. It's peaceful. Till something doesn't git the way you want haha. Happy bashingHello just finished working on this "T2M serie 5000". After buying a second engine, because the first one started leaking from bearings, the newer one leaked tooSo this is the 3rd engine: a "CEN NT16". Looks kinda overpowered for this car... might switch to a bigger clutchbell sooner or later. The idea was to put this NT16 in my new project, the "Carson Dazzler", but there is no space in that car in order to switch to a slidecarb. So I ended up putting it in the T2M, I had to improvise a lot but atleast there was the space for it

. Love the way things worked out, especially the rear exhaust! I'll make a hole for it in the bodyView attachment 170133View attachment 170134View attachment 170135View attachment 170136View attachment 170137View attachment 170138

- Thread starter

- #4

ThanksHell yeah man good job. Bet she rips. Smart thinking...

Yes! The crank was 0.01cm too long, which is why it touched the brake's screw. Couldn't move the engine to the back but figured it outNice work. I love working on them. It's peaceful. Till something doesn't git the way you want haha. Happy bashing

Wanted to bash it today but I already started on my next project, Carson Dazzler

STONER RC

BUILD it, SEND it, BASH it, FIX it, REPEAT

Lifetime Supporter!

Supporter

Excellence Award

Hospitality Award

Build Thread Contributor

- Messages

- 4,429

- Reaction score

- 3,862

- Location

- Brick, New Jersey

- RC Driving Style

- Bashing

- Racing

- Crawling

- Scale Builder

- Flying

- Boating

I would have just grinded down the end of the crank. Or changed out the brake screws for shorter ones. Servo horns are a easy fix.Thanks

Yes! The crank was 0.01cm too long, which is why it touched the brake's screw. Couldn't move the engine to the back but figured it out. The middle servo arm also broke. But that was it, the rest went the way I wanted

Wanted to bash it today but I already started on my next project, Carson Dazzler

Glad you got it worked out. And it went the way you wanted it too. Nicely done sir. Happy bashing...