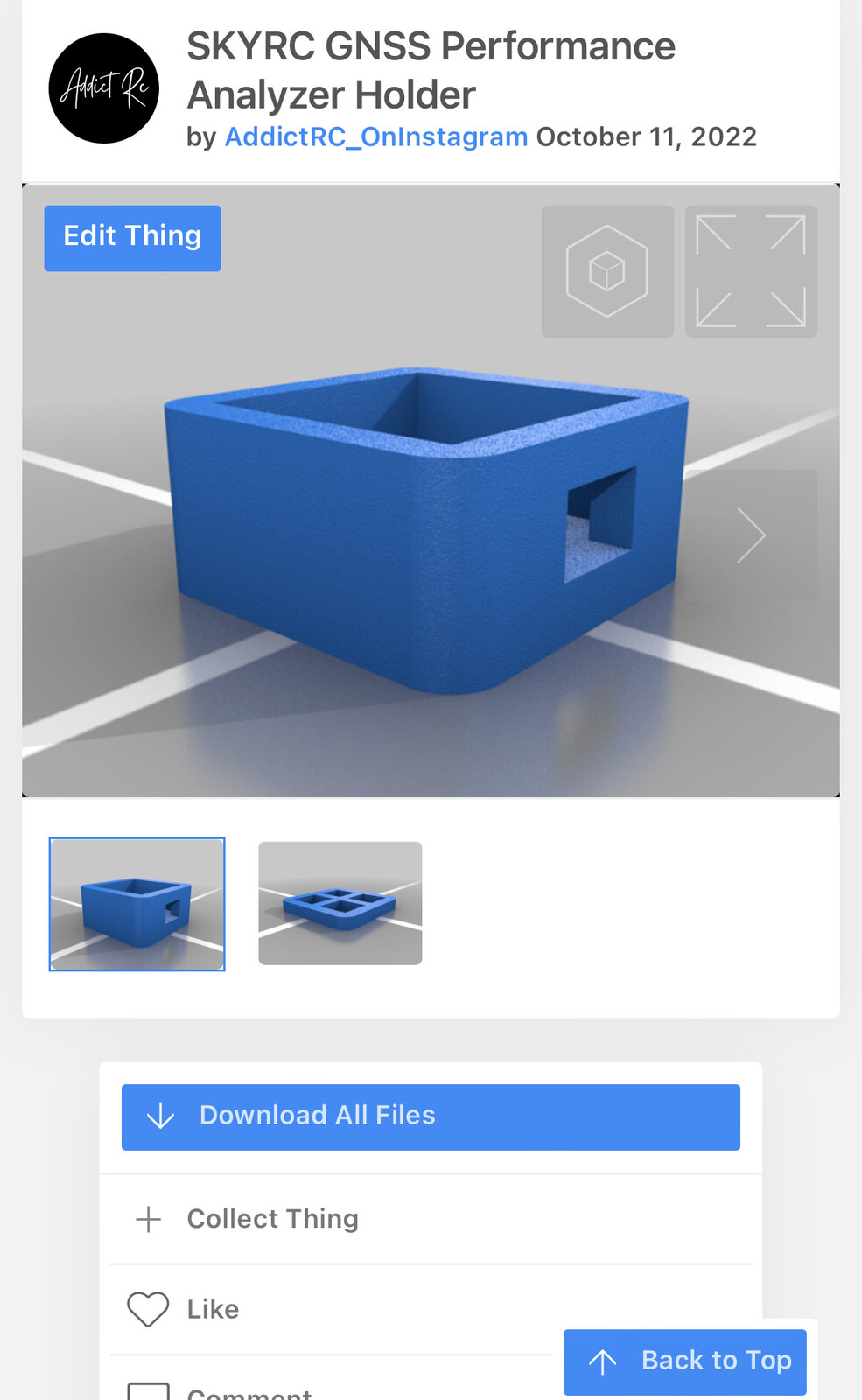

If anyone has a speedrun car or whatever and has a SKYRC GNSS here I made this ready to print 2 pieces must drill holes to secure pieces together, but here you go https://www.thingiverse.com/thing:5561241

Also to see all updates and designs go follow my Instagram just hit 1k followers recently https://instagram.com/addict.rc?r=nametag

Also to see all updates and designs go follow my Instagram just hit 1k followers recently https://instagram.com/addict.rc?r=nametag