ohmygahitscoby

Hardcore RCTalk User

Hey guys,

I just bought my flywheel (HPI 3-shoe flywheel for Savage) and Kyosho shoes (Aluminum shoes + 1.0 springs), and I noticed that it was fairly easy installing them. I'm not sure if I did anything wrong, but many people were having problems with their first time. So I want to see if I did do anything wrong or it's all correct. My idea was that I put the flywheel nut upside down, which made it easier, but I'm uncertain. Also, the CB is a bit over the clutch shoes, but it says that you don't want to see the shoes with the CB on. This happen with this combo and also with the Integy flywheel and shoes combo (Aluminum). I did not shim under the CB, so it's like that. One last thing, if I want to add shims to reduce the space of the CB going back and forth, do I add it above or below the CB? If anyone can point out where I went wrong, I'd be glad. Thanks!

Pictures:

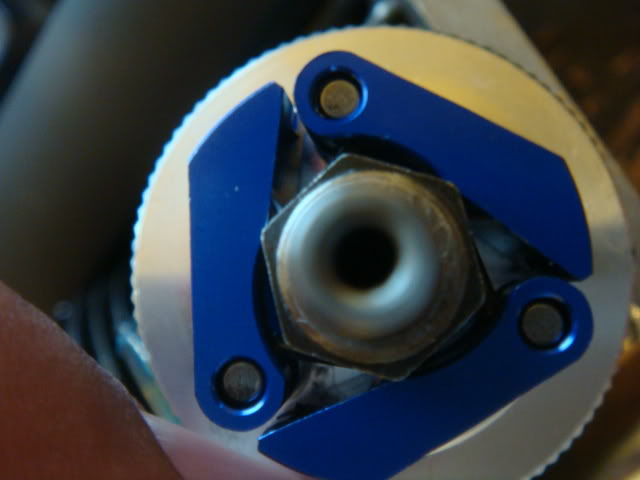

Picture of two shoes on the flywheel. You can also see direction of flywheel nut.

Picture of all shoes installed.

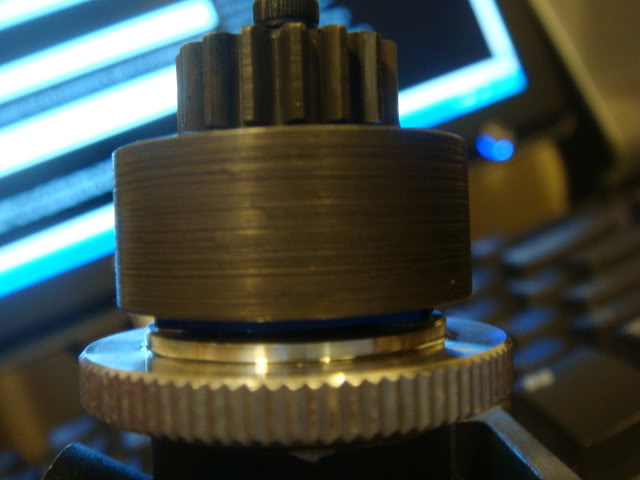

Picture with CB on.

-Coby

I just bought my flywheel (HPI 3-shoe flywheel for Savage) and Kyosho shoes (Aluminum shoes + 1.0 springs), and I noticed that it was fairly easy installing them. I'm not sure if I did anything wrong, but many people were having problems with their first time. So I want to see if I did do anything wrong or it's all correct. My idea was that I put the flywheel nut upside down, which made it easier, but I'm uncertain. Also, the CB is a bit over the clutch shoes, but it says that you don't want to see the shoes with the CB on. This happen with this combo and also with the Integy flywheel and shoes combo (Aluminum). I did not shim under the CB, so it's like that. One last thing, if I want to add shims to reduce the space of the CB going back and forth, do I add it above or below the CB? If anyone can point out where I went wrong, I'd be glad. Thanks!

Pictures:

Picture of two shoes on the flywheel. You can also see direction of flywheel nut.

Picture of all shoes installed.

Picture with CB on.

-Coby

Last edited:

?

?