trailsnail

RCTalk Member

- Messages

- 36

- Reaction score

- 0

- RC Driving Style

Well, over the last couple of days, I made my own setup system to get some more accuracy in setting up caster, camber, etc. I just couldn't see spending $100 - $300 for a hudy setup. The principle of what I made for the Revo was the same mostly, and it'll do what I need for my ride. I don't race and don't really bash hard, I just run the car and enjoy it. When I do run it, I like it to drive strait and handle well. Anyways, here goes.

I didn't like trying to eyeball all of the adjustments at the wheels. After running the car and having to trim it right 13, I knew there needed to be a better way. It wasn't accurate enough for me eyeball. I knew I needed to do something so I had an idea of using plexi glass. This provided me with some strait edges to get accurate measurements from. Trying to measure at the tires that may or may not be glued exactly right (I mean that one of them may be glued in the rim deeper than another ) bugged me.

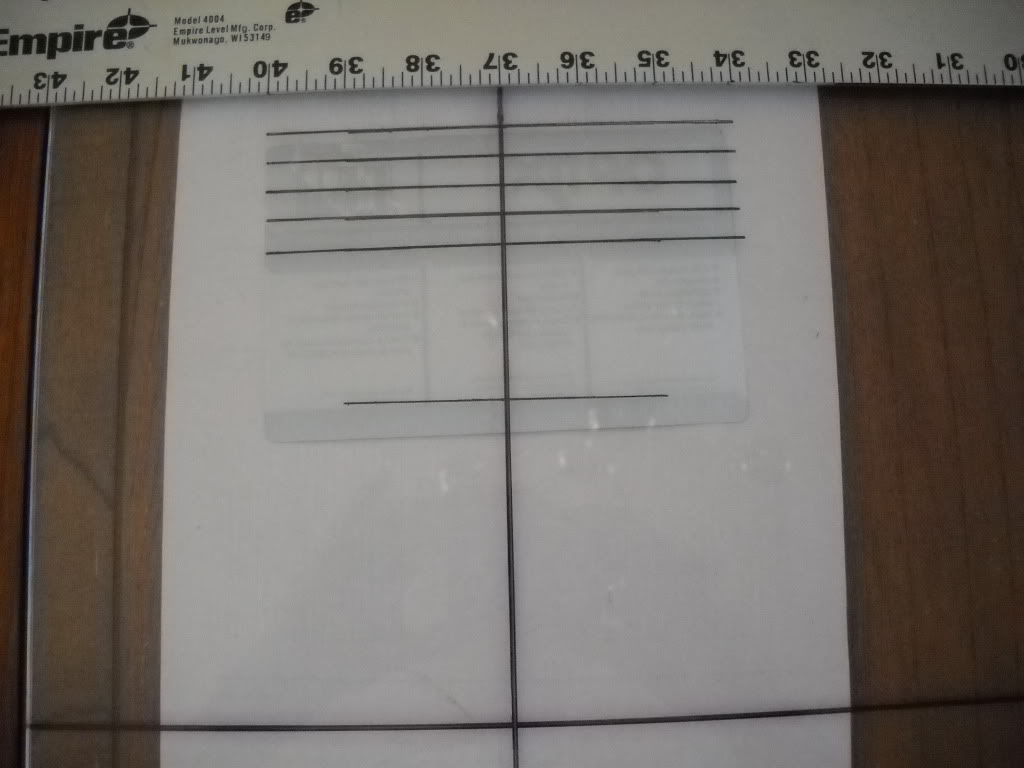

I started out with two pieces of 8" x 10" x 2mm of Plexi glass (lexan glass). These two pieces were cut down to 6" squares. I cut the squares with a utility knife and it worked relatively well. I've used this method before with success, and thought that on 2mm glass it'd work. Basically, I made the measurements, marked the plastic covering on the glass with marker, made the cuts (3-4 cuts) on the lines using a metal strait edge to guide the knife before broke the pieces I didn't need off. Once the squares were made, I made more measurements to find the centers of the 6" squares. Once the centers were found I used a pilot drill bit on my dremel press, and then finished it off with a 6mm bit. This is what I ended up with:

The arrows on the pieces show the corner (leading edge) of the glass that is factory cut on both sides. This gives me the best possible edge to set the truck on and make measurements from. While the edges where I cut are strait, they are also not as clean as the factory ones.

Once they were made, I added center lines for additional accuracy.

Next step was to make the base. For the base I used a piece of thicker glass that was 24" x 18". I left this piece the factory size. I also grabbed my metal strait edge, permanent markers, non permanent markers (which I didn't end up using), and a marker eraser (the white one in the middle).

First thing I did to the board was remove the plastic film from one side and draw a center line.

Then I about crapped my pants and realized that I have some serious sucking up to do with the wife. I hit a Christmas ball that my wife and I have had since our first Christmas, 14 years ago, and broke it. Talking about palm face plant!

And double crap!

Got the mess cleaned up, sucked up praising the wife as my goddess for 20 minutes, and went back to work.

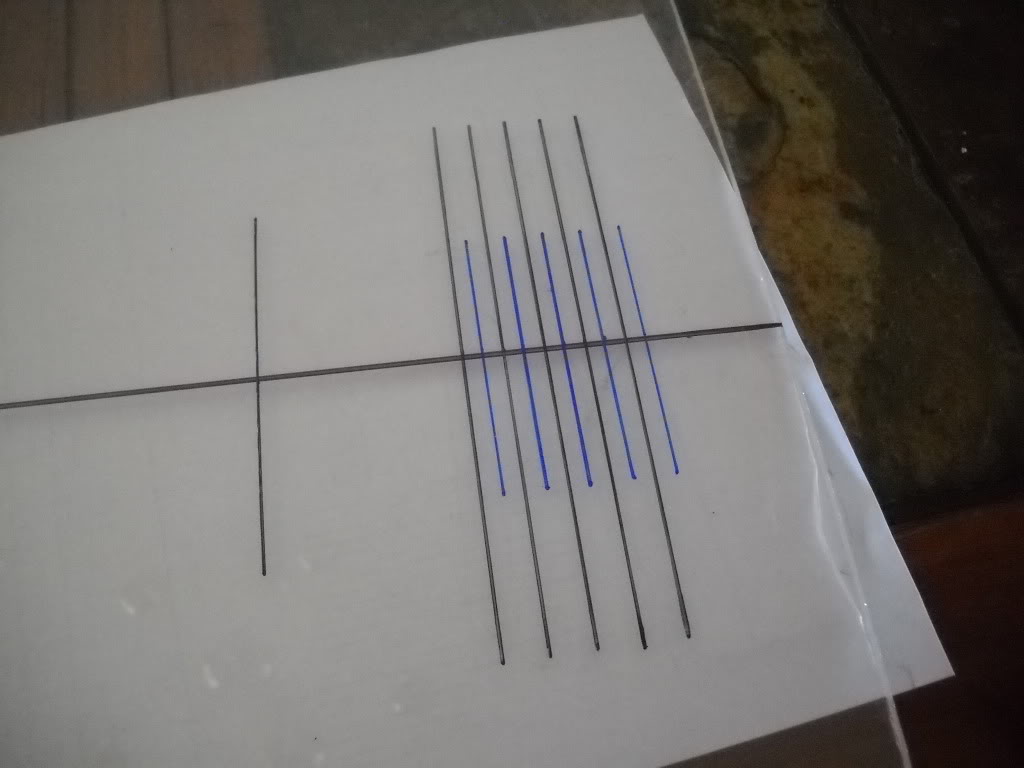

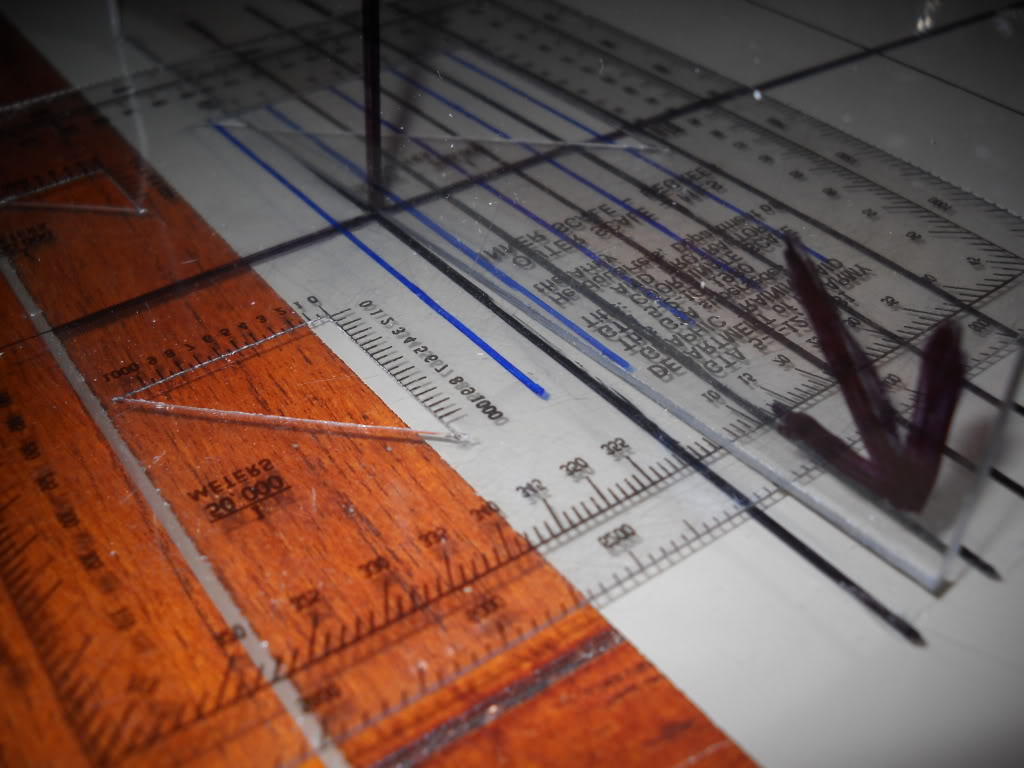

Then what I will call axle lines. On the axle lines I made more marks. The first one was at 10cm from center, then at 15cm from center and 1cm each line after that. The long line in the picture is actually the axle line.

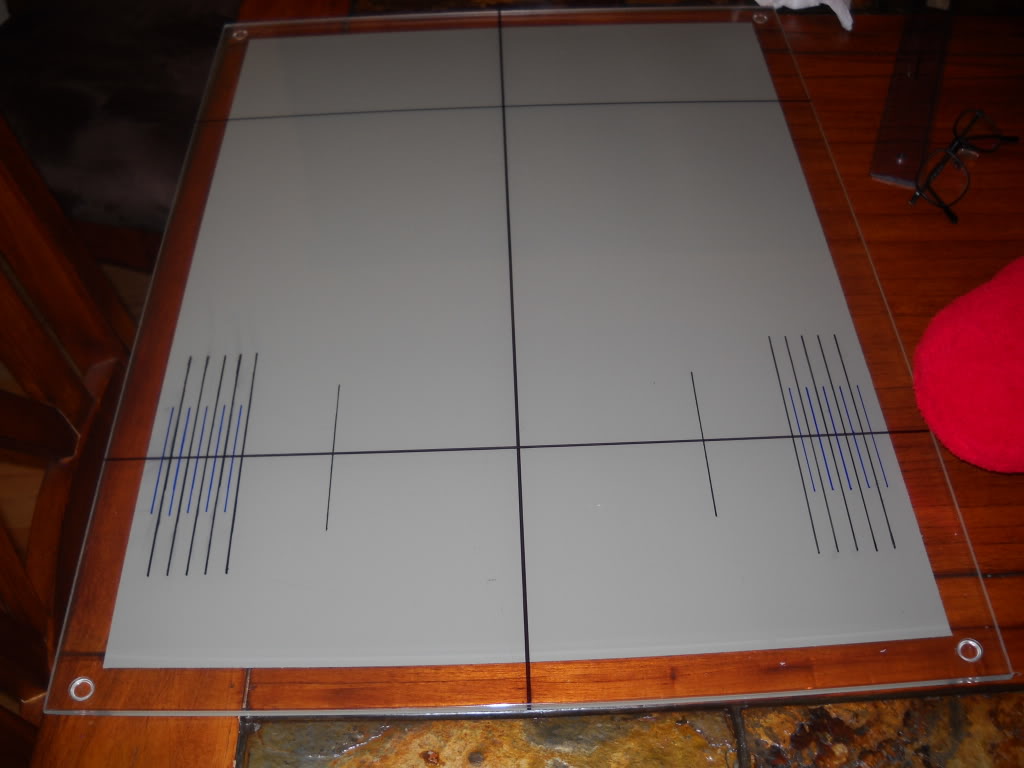

This is what the above looked like after I was done.

The measurements I used were what I got off of my ride. Axle width of 37" and axle to axle of 32". Remember, the axle width will change with how the pillow balls are set into the arms.

Some shorter blue lines 1/2 cm between the longer black lines.

And the completed product. I used some paper while drawing the lines for contrast. After I was done, I masked the edges and painted the underside. I also had some rubber feet that I added to the corners.

Leaving the glass clear wasn't an option because it would have made the lines too hard to see. Especially on my black work bench. Prior to painting the glass, I removed the film from the back side, and cleaned with denatured alcohol.

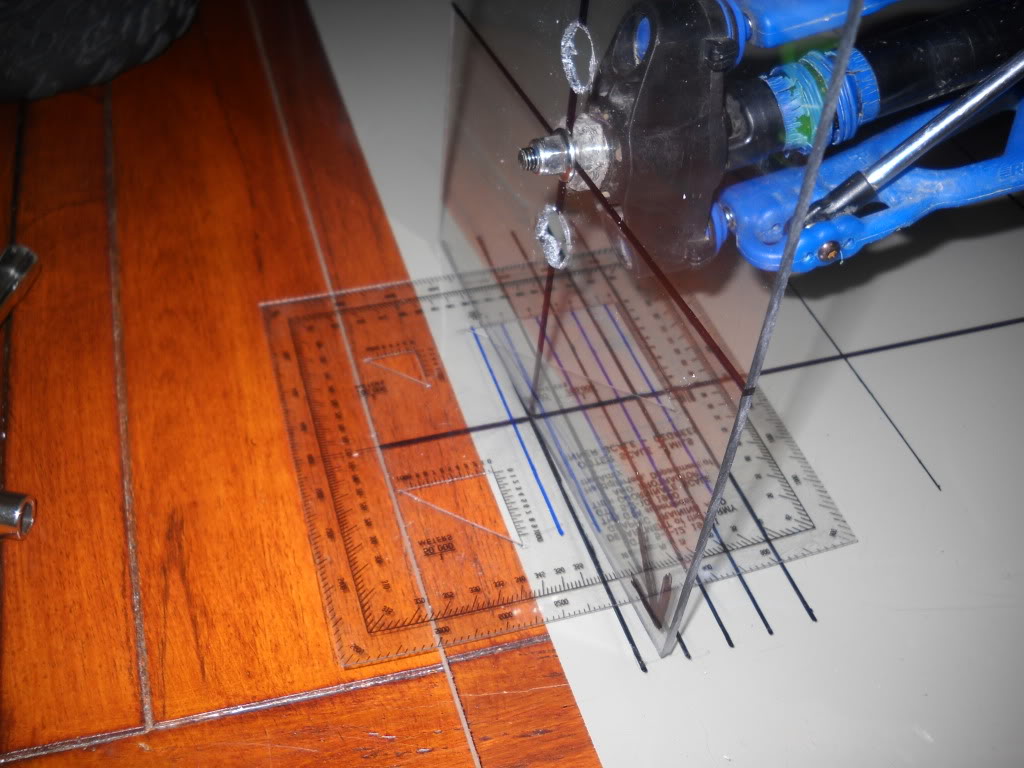

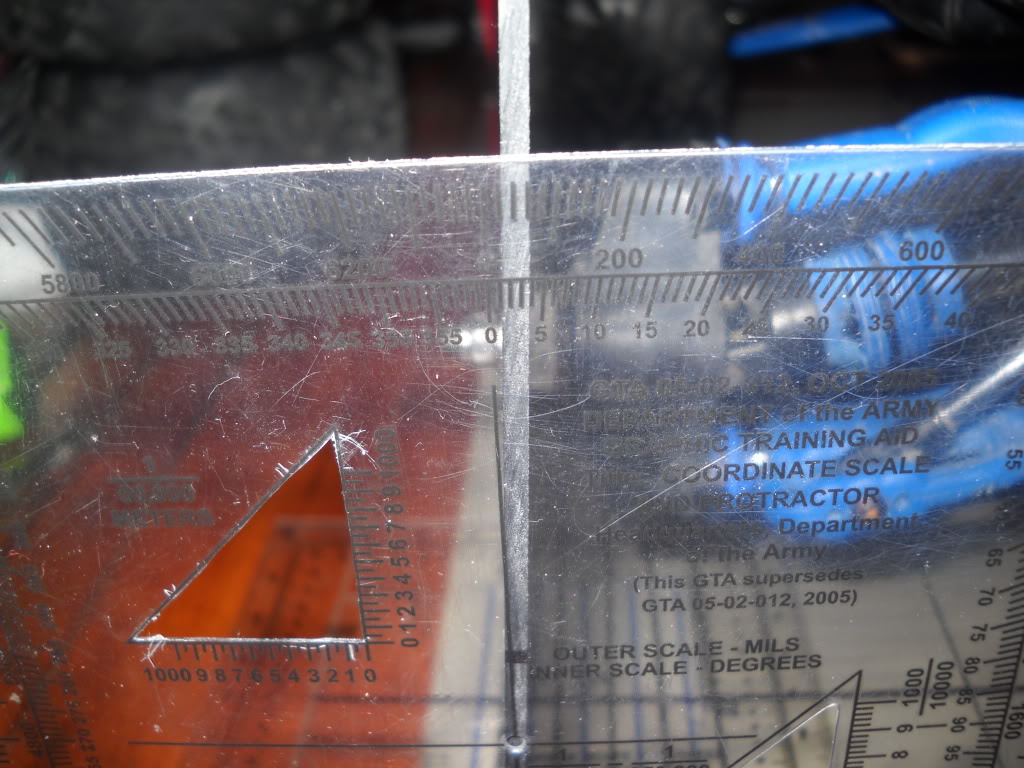

Here's pics of the finished product. I am using some military style protractors. They have 360 degrees marked on them and cross lines in the middle so they can be centered well with the board. Eventually I'll get a camber gauge, but that's a few weeks away. I make sure that the squares are centered on the axle line, and make adjustments as I see fit. The 1/2" holes for the pillow ball adjustments aren't as clean as I would have liked, but it works for what I need and allows for camber adjustments. Easier than having to measure, remove the wheel, adjust, replace wheel, etc, etc, etc.

Hope this helps someone else out. There was a total cost for me of around $24 for the glass. Paint, markers, etc, I had already at the house. I think with the spare pieces I have left from cutting the 6" square, I'll make some mounts for the rear wheels.

I didn't like trying to eyeball all of the adjustments at the wheels. After running the car and having to trim it right 13, I knew there needed to be a better way. It wasn't accurate enough for me eyeball. I knew I needed to do something so I had an idea of using plexi glass. This provided me with some strait edges to get accurate measurements from. Trying to measure at the tires that may or may not be glued exactly right (I mean that one of them may be glued in the rim deeper than another ) bugged me.

I started out with two pieces of 8" x 10" x 2mm of Plexi glass (lexan glass). These two pieces were cut down to 6" squares. I cut the squares with a utility knife and it worked relatively well. I've used this method before with success, and thought that on 2mm glass it'd work. Basically, I made the measurements, marked the plastic covering on the glass with marker, made the cuts (3-4 cuts) on the lines using a metal strait edge to guide the knife before broke the pieces I didn't need off. Once the squares were made, I made more measurements to find the centers of the 6" squares. Once the centers were found I used a pilot drill bit on my dremel press, and then finished it off with a 6mm bit. This is what I ended up with:

The arrows on the pieces show the corner (leading edge) of the glass that is factory cut on both sides. This gives me the best possible edge to set the truck on and make measurements from. While the edges where I cut are strait, they are also not as clean as the factory ones.

Once they were made, I added center lines for additional accuracy.

Next step was to make the base. For the base I used a piece of thicker glass that was 24" x 18". I left this piece the factory size. I also grabbed my metal strait edge, permanent markers, non permanent markers (which I didn't end up using), and a marker eraser (the white one in the middle).

First thing I did to the board was remove the plastic film from one side and draw a center line.

Then I about crapped my pants and realized that I have some serious sucking up to do with the wife. I hit a Christmas ball that my wife and I have had since our first Christmas, 14 years ago, and broke it. Talking about palm face plant!

And double crap!

Got the mess cleaned up, sucked up praising the wife as my goddess for 20 minutes, and went back to work.

Then what I will call axle lines. On the axle lines I made more marks. The first one was at 10cm from center, then at 15cm from center and 1cm each line after that. The long line in the picture is actually the axle line.

This is what the above looked like after I was done.

The measurements I used were what I got off of my ride. Axle width of 37" and axle to axle of 32". Remember, the axle width will change with how the pillow balls are set into the arms.

Some shorter blue lines 1/2 cm between the longer black lines.

And the completed product. I used some paper while drawing the lines for contrast. After I was done, I masked the edges and painted the underside. I also had some rubber feet that I added to the corners.

Leaving the glass clear wasn't an option because it would have made the lines too hard to see. Especially on my black work bench. Prior to painting the glass, I removed the film from the back side, and cleaned with denatured alcohol.

Here's pics of the finished product. I am using some military style protractors. They have 360 degrees marked on them and cross lines in the middle so they can be centered well with the board. Eventually I'll get a camber gauge, but that's a few weeks away. I make sure that the squares are centered on the axle line, and make adjustments as I see fit. The 1/2" holes for the pillow ball adjustments aren't as clean as I would have liked, but it works for what I need and allows for camber adjustments. Easier than having to measure, remove the wheel, adjust, replace wheel, etc, etc, etc.

Hope this helps someone else out. There was a total cost for me of around $24 for the glass. Paint, markers, etc, I had already at the house. I think with the spare pieces I have left from cutting the 6" square, I'll make some mounts for the rear wheels.