- Messages

- 1,321

- Reaction score

- 1,732

- RC Driving Style

- Racing

I have made a number of updates to this chassis since its inception. Most all of it was custom made/designed, but there were a few factory Traxxas items, albeit modified, that I used to complete it. These were front/rear bulkheads, suspension hinge mounts, and links for the wheelie bar. I really wanted to get away from having to mod parts to make it work. One, it's a PITA and easy to mess up. It's also messy when I have to grind down plastic, and it's time consuming. I've also found these parts out of stock more times than I 'd care for. Lastly, I'm able to cut down my costs and build time significantly.

I had tried resin printing in the past, but I wasn't entirely happy with the results and prep work. I recently stumbled upon "high impact" resin and saw it could come in different colors (like, why didn't I see this before?). Decided to give it another go. Well, the stuff was quite a bit tougher than other resins for sure. I tried to break it by throwing it. Could not. Ok, so it's "high impact" as advertised. Took beating it with a hammer to actually break it. (Note, regular resin completely shattered simply by throwing it hard on the floor, and the "softer" resin held up better but still broke after a bit of throwing around). The only issue I saw remaining was that threading was required in prep. So, I made some designs and put them to test. I noticed right away that while the threading was strong and held up, the bolts still tended to back out, and it was (much like factory parts) possible to overtighten and strip. Got to re-designing and decided it would be good to be able to have pockets to put in steel nuts. No chance of backing out, no chance of stripping. I tested these parts on my Mustang and they held up perfectly. I also tested a spare bulkhead by throwing it down hard on the pavement to the shock of my teammates, and it only received a minor chip/scuff mark. Alright then. It's a go

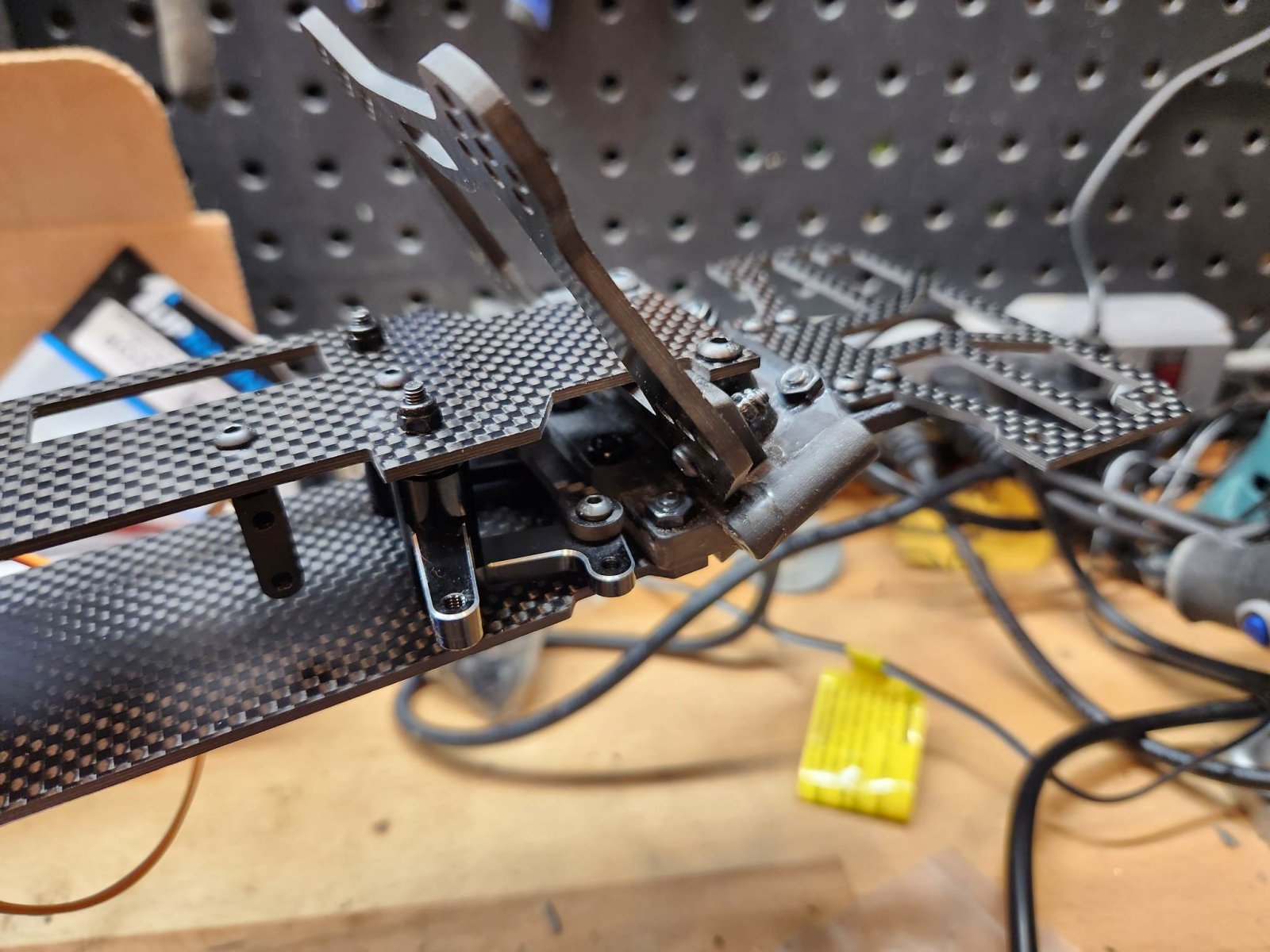

Front bulkhead. Backing nuts behind bolts, including slots for the top plate bolts.

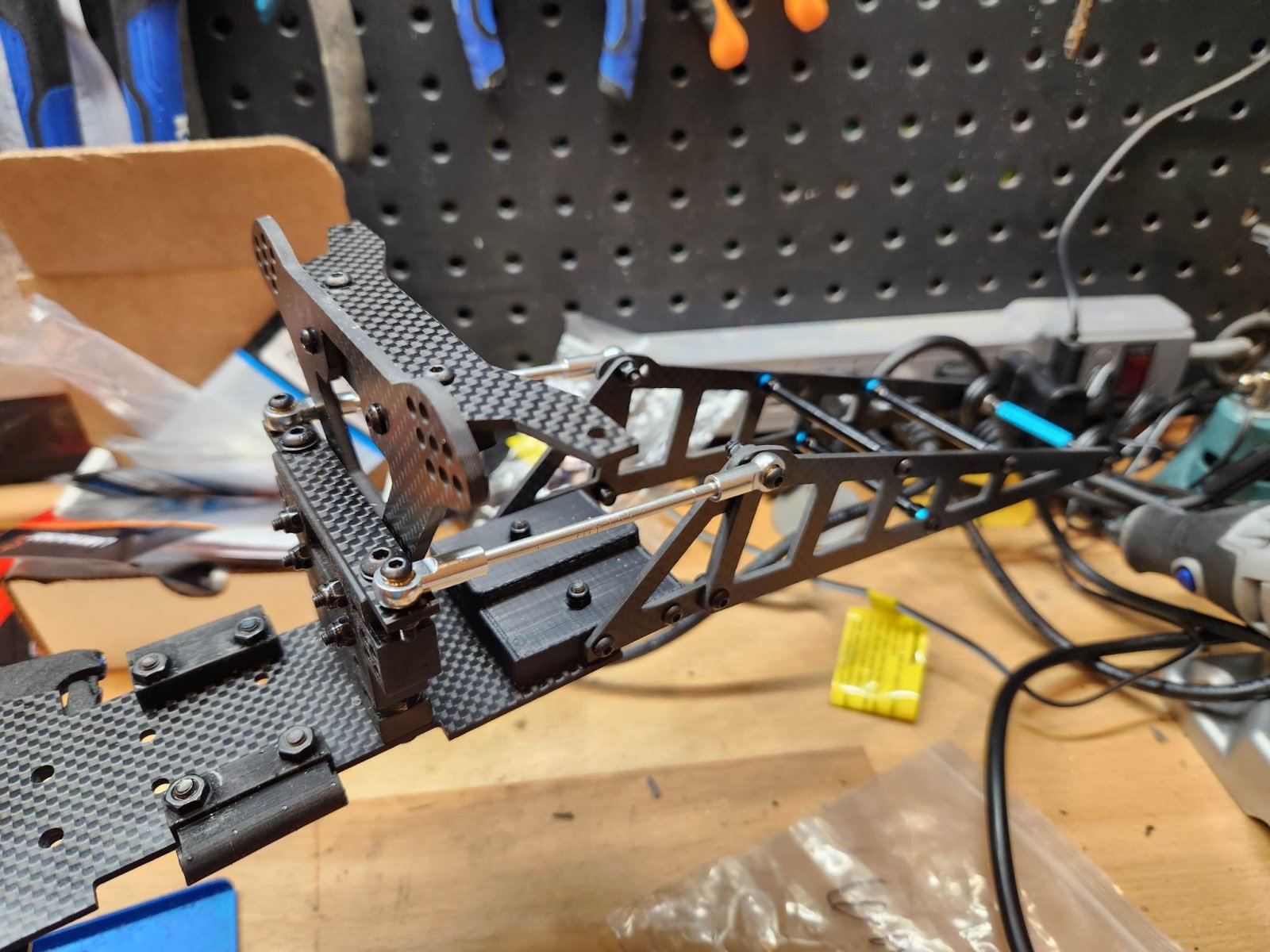

Rear bulkhead. Slots for backing bolts. Suspension mounts - threaded, with backing bolts. Note the new body mount plate too. Traxxas links now replaced with super lightweight aluminum struts that I cut and threaded myself.

This is the 17th chassis I've built now, and it's on its way to a customer. So far the feedback and input from my customers has been amazingly helpful, and I truly appreciate their patience realizing how the design would evolve as it got more use. I've been making sure to take care of the guys that have broken anything in crashes (which hasn't happened that much), as well as updating their parts if defects were discovered. I find there's always room for improvement, so I will never say this is a "final" design, but I can say that it's now a design that I'm no longer dependent on factory parts. The only non-built parts are the Hot Racing bell crank and the wheelie bar wheels. I'm strongly considering machining my own aluminum wheelie bar wheels very soon actually.

I had tried resin printing in the past, but I wasn't entirely happy with the results and prep work. I recently stumbled upon "high impact" resin and saw it could come in different colors (like, why didn't I see this before?). Decided to give it another go. Well, the stuff was quite a bit tougher than other resins for sure. I tried to break it by throwing it. Could not. Ok, so it's "high impact" as advertised. Took beating it with a hammer to actually break it. (Note, regular resin completely shattered simply by throwing it hard on the floor, and the "softer" resin held up better but still broke after a bit of throwing around). The only issue I saw remaining was that threading was required in prep. So, I made some designs and put them to test. I noticed right away that while the threading was strong and held up, the bolts still tended to back out, and it was (much like factory parts) possible to overtighten and strip. Got to re-designing and decided it would be good to be able to have pockets to put in steel nuts. No chance of backing out, no chance of stripping. I tested these parts on my Mustang and they held up perfectly. I also tested a spare bulkhead by throwing it down hard on the pavement to the shock of my teammates, and it only received a minor chip/scuff mark. Alright then. It's a go

Front bulkhead. Backing nuts behind bolts, including slots for the top plate bolts.

Rear bulkhead. Slots for backing bolts. Suspension mounts - threaded, with backing bolts. Note the new body mount plate too. Traxxas links now replaced with super lightweight aluminum struts that I cut and threaded myself.

This is the 17th chassis I've built now, and it's on its way to a customer. So far the feedback and input from my customers has been amazingly helpful, and I truly appreciate their patience realizing how the design would evolve as it got more use. I've been making sure to take care of the guys that have broken anything in crashes (which hasn't happened that much), as well as updating their parts if defects were discovered. I find there's always room for improvement, so I will never say this is a "final" design, but I can say that it's now a design that I'm no longer dependent on factory parts. The only non-built parts are the Hot Racing bell crank and the wheelie bar wheels. I'm strongly considering machining my own aluminum wheelie bar wheels very soon actually.