ohmygahitscoby

Hardcore RCTalk User

Hey guys,

I would think this would go here, it is the Electric Talk section.

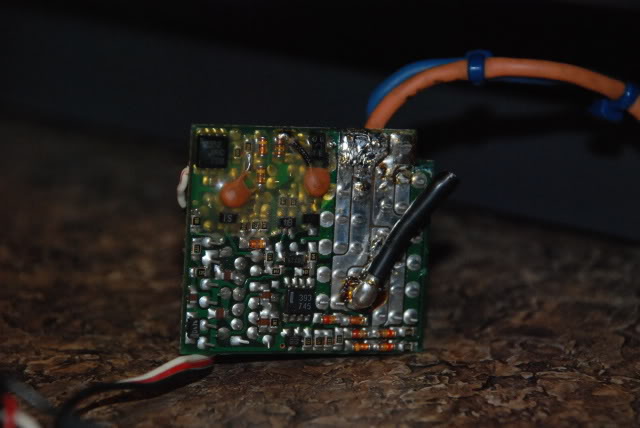

Anyways, I was soldering on new plugs to the circuit board of my ESC, and chaos happened. I tried applying heat to the ugly solder, but no use. Does anybody know a tool I can use to clean up this monster ugly solder job?

Top right

Thanks!

-Coby

I would think this would go here, it is the Electric Talk section.

Anyways, I was soldering on new plugs to the circuit board of my ESC, and chaos happened. I tried applying heat to the ugly solder, but no use. Does anybody know a tool I can use to clean up this monster ugly solder job?

Top right

Thanks!

-Coby